Abstract

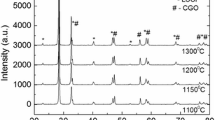

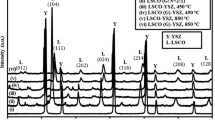

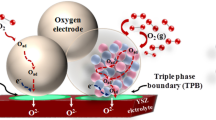

LSM–ScSZ composite electrode for solid oxide fuel cells (SOFCs) cathode application has been investigated for its oxygen reduction reaction (ORR) performance. The composition and sintering temperature of LSM–ScSZ were controlled to determine the optimized microstructure of the LSM–ScSZ electrode layer, considering its length of triple-phase boundaries (TPBs), and transfer of oxygen for cathode reaction. The electrochemical impedance spectroscopy (EIS) method with an equivalent circuit model was introduced to characterize the specific impedance of each sample. The results demonstrated that volume ratio of LSM:ScSZ = 6:4 sintered at 1200 °C sample showed the lowest total impedance of 0.031 Ω cm2 at 900 °C operating temperature, compensating slightly increased high-frequency impedance (RHF) of TPBs region with drastically improved the active surface of LSM area and their connectivity, which correspond to middle- and low-frequency impedance (RMF and RLF) value, respectively. This study suggests an integrated approach in the development of the SOFCs cathode design with the proper compositional ratio and sintering process via using commercial materials.

Similar content being viewed by others

References

J.T.S. Irvine, D. Neagu, M.C. Verbraeken et al., Evolution of the electrochemical interface in high-temperature fuel cells and electrolysers. Nat Energy 1, 1–13 (2016). https://doi.org/10.1038/nenergy.2015.14

P.A. Connor, X. Yue, C.D. Savaniu et al., Tailoring SOFC electrode microstructures for improved performance. Adv Energy Mater 8, 1–20 (2018). https://doi.org/10.1002/aenm.201800120

S. Hussain, L. Yangping, Review of solid oxide fuel cell materials: cathode, anode, and electrolyte. Energy Transit 4, 113–126 (2020). https://doi.org/10.1007/s41825-020-00029-8

E.V. Tsipis, V.V. Kharton, Electrode materials and reaction mechanisms in solid oxide fuel cells: a brief review: I Electrochemical behavior vs materials science aspects. J Solid State Electrochem 12, 1367–1391 (2008). https://doi.org/10.1007/s10008-008-0611-6

J.W. Shin, D. Go, S.H. Kye et al., Review on process-microstructure-performance relationship in ALD-engineered SOFCs. J Phys Energy 1, 042002 (2019). https://doi.org/10.1088/2515-7655/ab30a0

J. Ascolani-Yael, A. Montenegro-Hernández et al., The oxygen reduction reaction in solid oxide fuel cells: from kinetic parameters measurements to electrode design. J Phys Energy 2, 042004 (2020). https://doi.org/10.1088/2515-7655/abb4ec

W.H. Kan, A.J. Samson, V. Thangadurai, Trends in electrode development for next generation solid oxide fuel cells. J Mater Chem A 4, 17913–17932 (2016). https://doi.org/10.1039/c6ta06757c

H. Fukunaga, M. Ihara, K. Sakaki et al., The relationship between overpotential and the three phase boundary length. Solid State Ionics 86–88, 1179–1185 (1996). https://doi.org/10.1016/0167-2738(96)00284-6

D. Ding, X. Li, S.Y. Lai et al., Enhancing SOFC cathode performance by surface modification through infiltration. Energy Environ Sci 7, 552–575 (2014). https://doi.org/10.1039/c3ee42926a

R.R. Romero, A.G. Báez, A.M.N. Garza et al., A review of wet impregnation—an alternative method for the fabrication of high performance and nano-structured electrodes of solid oxide fuel cell. Vet Mex 42, 331–338 (2011)

S.P. Jiang, Nanoscale and nano-structured electrodes of solid oxide fuel cells by infiltration: advances and challenges. Int J Hydrogen Energy 37, 449–470 (2012). https://doi.org/10.1016/j.ijhydene.2011.09.067

N. Imanishi, R. Ohno, K. Murata et al., LSM-YSZ cathode with infiltrated cobalt oxide and cerium oxide nanoparticles. Fuel Cells 9, 215–221 (2009). https://doi.org/10.1002/fuce.200800090

Y. Jeon, J.H. Myung, S.-H. Hyun et al., Corn-cob like nanofibres as cathode catalysts for an effective microstructure design in solid oxide fuel cells. J Mater Chem A 5, 3966–3973 (2017). https://doi.org/10.1039/c6ta08692f

G. Chen, Y. Gao, Y. Luo et al., Effect of A site deficiency of LSM cathode on the electrochemical performance of SOFCs with stabilized zirconia electrolyte. Ceram Int 43, 1304–1309 (2017). https://doi.org/10.1016/j.ceramint.2016.10.082

J.H. Kim, A. Manthiram, Layered LnBaCo2O5+δ perovskite cathodes for solid oxide fuel cells: an overview and perspective. J Mater Chem A 3, 24195–24210 (2015). https://doi.org/10.1039/c5ta06212h

Z. Shao, S.M. Halle, A high-performance cathode for the next generation of solid-oxide fuel cells. Nature 431, 170–173 (2004). https://doi.org/10.1038/nature02863

B. Ahmed, S.B. Lee, R.H. Song et al., A study on sintering inhibition of La0.8Sr0.2 MnO3-∂ cathode material for cathode-supported fuel cells. J Korean Ceram Soc 53(4), 94–99 (2016). https://doi.org/10.4191/kcers.2016.53.5.494

N. Hobara, K. Takizawa, A. Hagiwara et al., Effect of process parameters on electrochemical properties of mechanically prepared composite powders for solid oxide fuel cells. Adv Powder Technol 22, 102–107 (2011). https://doi.org/10.1016/j.apt.2010.08.004

Z. Wang, M. Cheng, Y. Dong et al., Investigation of LSM1.1-ScSZ composite cathodes for anode-supported solid oxide fuel cells. Solid State Ionics 176, 2555–2561 (2005). https://doi.org/10.1016/j.ssi.2005.07.013

E. Lee, H. Jeong, T.H. Shin et al., Determination of the rate-determining step of the oxygen reduction reaction of La0.8Sr0.2MnO3 (LSM)-8mol% yttria-stabilized zirconia(YSZ): Composition and microstructure. Ceram Int 47, 1792–1797 (2021). https://doi.org/10.1016/j.ceramint.2020.09.005

H. Shimada, K. Takizawa, H. Michibata et al., Equivalent circuit model analysis of microstructure-controlled LSM/ScSZ composite cathodes by powder slurry impregnation method. J Electrochem Soc 162, F40-53 (2015). https://doi.org/10.1149/2.0211501jes

S.B. Adler, Factors governing oxygen reduction in solid oxide fuel cell cathodes. Chem Rev 104, 4791–4843 (2004). https://doi.org/10.1021/cr020724o

F.H. Van Heuveln, H.J.M. Bouwmeester, F.P.F. Van Berkel, Electrode properties of Sr-doped LaMnO3 on yttria-stabilized zirconia: I. Three-phase boundary area. J Electrochem Soc 144, 126–133 (1997). https://doi.org/10.1149/1.1837374

J.D. Kim, G.D. Kim, J.W. Moon et al., Characterization of LSM-YSZ composite electrode by ac impedance spectroscopy. Solid State Ionics 143, 379–389 (2001). https://doi.org/10.1016/S0167-2738(01)00877-3

T.M.M. Heenan, X. Lu, D.P. Finegan et al., Evaluating microstructure evolution in an SOFC electrode using digital volume correlation. Sustain Energy Fuels 2, 2625–2635 (2018). https://doi.org/10.1039/c8se00292d

O.O. Agbede, K. Hellgardt, G.H. Kelsall, Electrical conductivities and microstructures of LSM, LSM-YSZ and LSM-YSZ/LSM cathodes fabricated on YSZ electrolyte hollow fibres by dip-coating. Mater Today Chem 16, 100252 (2020). https://doi.org/10.1016/j.mtchem.2020.100252

T. Tsai, S.A. Barnett, Effect of LSM-YSZ cathode on thin-electrolyte solid oxide fuel cell performance. Solid State Ionics 93, 207–217 (1997). https://doi.org/10.1016/s0167-2738(96)00524-3

J.C. Marrero, N.F.P. Ribeiro, C.F. Malfatti et al., Characterization of yttria-stabilized zirconia films deposited by dip-coating on La0.7Sr0.3MnO3 substrate: Influence of synthesis parameters. J Adv Ceram 2, 55–62 (2013). https://doi.org/10.1007/s40145-013-0042-4

A. Panghal, P.K. Kulriya, Y. Kumar et al., Investigations of atomic disorder and grain growth kinetics in polycrystalline La2Zr2O7. Appl Phys A Mater Sci Process 125, 1–11 (2019). https://doi.org/10.1007/s00339-019-2720-8

A. Chen, J.R. Smith, K.L. Duncan et al., Effect of La2Zr2O7 on interfacial resistance in solid oxide fuel cells. J Electrochem Soc 157, B1624 (2010). https://doi.org/10.1149/1.3484092

Acknowledgements

This work was supported by Research Assistance Program (2019) in the Incheon National University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Jeong, H., Sharma, B., Jo, S. et al. Electrochemical characteristics of La0.8Sr0.2MnO3 (LSM)–scandia-stabilized zirconia (ScSZ) composite cathode. J. Korean Ceram. Soc. 59, 473–479 (2022). https://doi.org/10.1007/s43207-022-00200-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43207-022-00200-5