Abstract

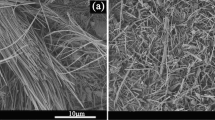

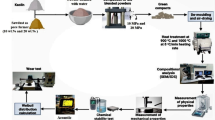

Zeolite-based porous ceramics were developed using inexpensive natural zeolite powder with B2O3, Bi2O3, and SiO2 additives and sintered at low temperatures (500–600 °C) compared to those in previous studies (800–1300 °C). The effects of sintering temperature on the porosity, microstructure, flexural strength, thermal conductivity, and water absorption capacity were investigated. As the sintering temperature increased from 500 to 600 °C, the porosity of the zeolite-based porous ceramics decreased from 49.6 to 45.7%, which is attributed to improved densification at high temperature via viscous flow of the glass phase. The flexural strength and thermal conductivity increased from 5.4 to 11.9 MPa and from 0.19 to 0.30 W/mK, respectively, with increasing sintering temperature. The samples sintered at 550 and 600 °C were highly stable in water, with high absorption capacities of 37.6 and 34.1 wt%, respectively. The typical flexural strength, thermal conductivity, and water absorption capacity of the zeolite-based porous ceramic sintered at 550 °C (~ 46% porosity) were 8.4 MPa, 0.24 W/mK, and 37.6%, respectively.

Similar content being viewed by others

Availability of data and material

The material and data are available from the authors upon reasonable request.

Code availability

This study does not cover custom computer code or algorithm.

References

M.W. Ackley, S.U. Rege, H. Saxena, Microporous Mesoporous Mater. (2003). https://doi.org/10.1016/S1387-1811(03)00353-6

R. Roque-Malherbe, W.D. Valle, F. Marquez, J. Duconge, M.F.A. Goosen, Sep. Sci. Technol. (2006). https://doi.org/10.1080/01496390500446277

J. Cui, X. Zhang, H. Liu, S. Liu, K.L. Yeung, J. Membr. Sci. (2008). https://doi.org/10.1016/j.memsci.2008.08.015

B. Kim, S. Lee, J. Korean Ceram. Soc. (2020). https://doi.org/10.1007/s43207-020-00043-y

B. Gao, S. Jang, H. Son, H.J. Lee, H.J. Lee, J.J. Yang, C.J. Bae, J. Korean Ceram. Soc. (2020). https://doi.org/10.1007/s43207-020-00075-4

Y. Tian, Y. Tang, J. Wang, R. Zhang, X. Yan, G. Peng, L. Fang, Q. Jing, Int. J. Appl. Ceram. Technol. (2020). https://doi.org/10.1111/ijac.13468

R.S. Bowman, Microporous Mesoporous Mater. (2003). https://doi.org/10.1016/S1387-1811(03)00354-8

S. Wang, Y. Peng, Chem. Eng. J. 156, 11–24 (2010). https://doi.org/10.1016/j.cej.2009.10.029

I. Solmus, C. Yamali, B. Kaftanoglu, D. Baker, A. Caglar, Appl. Energy (2010). https://doi.org/10.1016/j.apenergy.2009.11.027

W. Wang, L. Wu, Z. Li, Y. Fang, J. Ding, J. Xiao, Dry. Technol. (2013). https://doi.org/10.1080/07373937.2013.792094

R. Konig, M. Spaggiari, O. Santoliquido, P. Principi, G. Bianchi, A. Ortona, J. Clean Prod. (2020). https://doi.org/10.1016/j.jclepro.2020.120500

B. Mendes, I.K. Andrade, J.M. de Carvalho, L. Pedroti, A. de Oliveira Junior, Int. J. Appl. Ceram. Technol. (2021). https://doi.org/10.1111/ijac.13635

R. Gusain, N. Kumar, S.S. Ray, Coord. Chem Rev. (2020). https://doi.org/10.1016/j.ccr.2019.213111

S. Kesraoui-Ouki, C.R. Cheeseman, R. Perry, J. Chem. Tech. Biotechnol. (1994). https://doi.org/10.1002/jctb.280590202

P. Misaelides, Microporous Mesoporous Mater. (2011). https://doi.org/10.1016/j.micromeso.2011.03.024

J. Janchen, D. Ackermann, H. Stach, W.B. Rosicke, Sol. Energy. (2004). https://doi.org/10.1016/j.solener.2003.07.036

M.M. Arimi, Prog. Nat. Sci: Mater. Int. (2017). https://doi.org/10.1016/j.pnsc.2017.02.001

A.C. Feltrin, H.M. de Souza, T.F. de Aquino, C.R.M. Marques, E. Angioletto, Int. J. Appl. Ceram. Technol. (2021). https://doi.org/10.1111/ijac.13744

D.A. White, R.L. Bussey, Separ Purif Technol. (1997). https://doi.org/10.1016/S1383-5866(97)00009-9

V.I. Vereshagin, S.N. Sokolova, Constr. Build. Mater. (2008). https://doi.org/10.1016/j.conbuildmat.2007.01.016

O. Şan, M. Koç, H. Cengizler, Ceram. Int. (2019). https://doi.org/10.1016/j.ceramint.2019.08.108

O. Şan, C. Özgür, Sintering effect on the microstructure of glassy porous ceramics. In: 6th International Advanced Technologies Symposium (IATS’11) Elazığ, Turkey, p. 132–135 (2011)

S. Yamanaka, P.B. Malla, S. Komarneni, Zeolites (1989). https://doi.org/10.1016/0144-2449(89)90004-3

E.P. Ng, S. Mintova, Microporous Mesoporous Mater. (2008). https://doi.org/10.1016/j.micromeso.2007.12.022

M. Raimondo, M. Dondi, D. Gardini, G. Guarini, F. Mazzanti, Constr. Build. Mater. (2009). https://doi.org/10.1016/j.conbuildmat.2009.01.009

J.H. Eom, Y.W. Kim, I.H. Song, J. Eur. Ceram. Soc. (2012). https://doi.org/10.1016/j.jeurceramsoc.2011.11.040

S.C. Kim, H.J. Yeom, Y.W. Kim, I.H. Song, J.H. Ha, Int. J. Appl. Ceram. Technol. (2017). https://doi.org/10.1111/ijac.12693

O. San, S. Abalı, C. Hosten, Ceram. Int. (2003). https://doi.org/10.1016/S0272-8842(03)00047-6

P. Hristov, A. Yoleva, S. Djambazov, I. Chukovska, D. Dimitrov, J. Univ. Chem. Technol. Metall. 47, 476–480 (2012)

H. Liu, C. Jie, Y. Ma, Z. Wang, X. Wang, Trans. Indian Ceram. Soc. (2020). https://doi.org/10.1080/0371750X.2020.1722754

M. Mohamed, N. Dayirou, H. Mohamed, N. André, L.N.G. Laure, N. Daniel, Trans Indian Ceram. Soc. (2020). https://doi.org/10.1080/0371750X.2019.1692695

S.M.B. Respati, R. Soenoko, Y.S. Irawan, W. Suprapto, Appl. Mech. Mater. (2016). https://doi.org/10.4028/www.scientific.net/AMM.836.219

T.J. Rockett, W.R. Foster, J. Am. Ceram. Soc. (1965). https://doi.org/10.1111/j.1151-2916.1965.tb11803.x

T. Takamori, J. Am. Ceram. Soc. (1990). https://doi.org/10.1111/j.1151-2916.1990.tb05112.x

H. Shao, T. Wang, Q. Zhang, J. Alloy Compd. (2009). https://doi.org/10.1016/j.jallcom.2009.03.186

A.I. Borhan, M. Gromada, G.G. Nedelcu, L. Leontie, Ceram. Int. (2016). https://doi.org/10.1016/j.ceramint.2016.03.199

S. Wu, X. Wei, X. Wang, H. Yang, S. Gao, J. Mater. Sci. Technol. (2010). https://doi.org/10.1016/S1005-0302(10)60075-8

K.W. Tay, Y.P. Fu, Q.F. Huang, F.H. Jang, Ceram. Int. (2010). https://doi.org/10.1016/j.ceramint.2009.12.021

K.W. Tay, Y.P. Fu, J.F. Huang, H.C. Huang, Ceram. Int. (2011). https://doi.org/10.1016/j.ceramint.2010.11.017

H. Doweidar, K. El-Egili, R. Ramadan, M. Al-Zaibani, J. Non-Cryst. Solids (2018). https://doi.org/10.1016/j.jnoncrysol.2018.01.025

T. Uchino, A. Aboshi, S. Kohara, Y. Ohishi, M. Shakashita, K. Aoki, Phys. Rev. B. (2004). https://doi.org/10.1103/PhysRevB.69.155409

S. Kultayeva, J.H. Ha, R. Malik, Y.W. Kim, K.J. Kim, J. Eur. Ceram. Soc. (2020). https://doi.org/10.1016/j.jeurceramsoc.2019.11.045

D. Zhao, K. Cleare, C. Oliver, C. Ingram, D. Cook, R. Szostak, L. Kevan, Microporous Mesoporous Mater. (1998). https://doi.org/10.1016/S1387-1811(98)00131-0

D.B. Akkoca, M. Yιlgιn, M. Ural, H. Akçin, A. Mergen, Geochem. Int. (2013). https://doi.org/10.1134/S0016702913040022

S.K. Wahono, D.J. Prasetyo, T.H. Jatmiko, A. Suwanto, D. Pratiwi, Hernawan, K. Vasilev, IOP Conf. Ser: Earth Environ. Sci. (2019). https://doi.org/10.1088/1755-1315/251/1/012009

G.E. Christidis, D. Moratis, E. Keheyan, L. Akhalbedashvili, N. Kekelidze, R. Gevorkyan, H. Yeritsyan, H. Sargsyan, Appl. Clay Sci. (2003). https://doi.org/10.1016/S0169-1317(03)00150-9

T. Tunç, A.Ş Demirkıran, Powder Technol. (2014). https://doi.org/10.1016/j.powtec.2014.03.069

F. Matteucci, M. Dondi, G. Guarini, Ceram. Int. (2002). https://doi.org/10.1016/S0272-8842(02)00067-6

S. Yuruyen, H.O. Toplan, Ceram. Int. (2009). https://doi.org/10.1016/j.ceramint.2009.02.005

J.H. Eom, Y.W. Kim, B.J. Jung, Ceram. Int. (2013). https://doi.org/10.1016/j.ceramint.2012.08.064

J.H. Eom, H.J. Yeom, Y.W. Kim, I.H. Song, Clays Clay. Miner. (2015). https://doi.org/10.1346/CCMN.2015.0630305

J. Rouquerol, G. Baron, R. Denoyel, H. Giesche, J. Groen, P. Klobes, P. Levitz, A.V. Neimark, S. Rigby, R. Skudas, K. Sing, M. Thommes, K. Unger, Pure. Appl. Chem. (2012). https://doi.org/10.1351/PAC-REP-10-11-19

M. Kruk, M. Jaroniec, Chem. Mater. (2001). https://doi.org/10.1021/cm0101069

R. Malik, Y.W. Kim, I.H. Song, J. Eur. Ceram. Soc. (2020). https://doi.org/10.1016/j.jeurceramsoc.2019.10.056

M. Fukushima, Y. Zhou, Y.I. Yoshizawa, H. Miyazaki, K. Hirao, J. Ceram. Soc. Jpn. (2006). https://doi.org/10.2109/jcersj.114.571

H.J. Yeom, S.C. Kim, Y.W. Kim, I.H. Song, Ceram. Int. (2016). https://doi.org/10.2109/jcersj.114.571

Y. Liu, Y. Su, J. Cao, J. Guan, L. Xu, R. Zhang, M. He, Q. Zhang, L. Fan, Z. Jiang, Nanoscale (2017). https://doi.org/10.1039/C7NR00818J

T. Ohji, M. Fukushima, Int. Mater. Rev. (2012). https://doi.org/10.1179/1743280411Y.0000000006

K.H. Zuo, Y.P. Zeng, D. Jiang, Int. J. Appl. Ceram. Technol. (2008). https://doi.org/10.1111/j.1744-7402.2008.02190.x

F.P. Knudsen, J Am Ceram. Soc. (1959). https://doi.org/10.1111/j.1151-2916.1959.tb13596.x

R.W. Rice, J. Mater. Sci. (1996). https://doi.org/10.1007/BF00357860

J.H. Eom, Y.W. Kim, J. Ceram. Soc. Jpn. (2008). https://doi.org/10.2109/jcersj2.116.1159

B.K. Nandi, R. Uppaluri, M.K. Purkait, Appl. Clay Sci. (2008). https://doi.org/10.1016/j.clay.2007.12.001

F. Bouzerara, S. Boulanacer, A. Harabi, B. Boudaira, S. Achour, S. Condom, Phys. Procedia. (2009). https://doi.org/10.1016/j.phpro.2009.11.115

J.H. Eom, Y.W. Kim, I.H. Song, J. Korean Ceram. Soc. (2013). https://doi.org/10.4191/kcers.2013.50.5.341

H. Aloulou, H. Bouhamed, A. Ghorbel, R.B. Amar, S. Khemakhem, Desalin. Water Treat. (2017). https://doi.org/10.5004/dwt.2017.21348

M.M. Bazin, N. Ahmad, Y. Nakamura, J. Asian Ceram. Soc. (2019). https://doi.org/10.1080/21870764.2019.1658339

S. Rajpoot, J.H. Ha, Y.W. Kim, K.J. Kim, J. Eur Ceram. Soc. (2020). https://doi.org/10.1016/j.jeurceramsoc.2020.04.018

S. Rajpoot, R. Malik, Y.W. Kim, Ceram. Int. (2019). https://doi.org/10.1016/j.ceramint.2019.07.109

W.L. Huo, X. Zhang, Z. Hu, Y. Chen, Y. Wang, J. Yang, J. Am. Ceram. Soc. (2019). https://doi.org/10.1111/jace.16115

H. Mori, Y. Hamamoto, S. Yoshida, Trans. Jpn. Soc. Refrig. Air. Cond. Eng. (2000). https://doi.org/10.11322/tjsrae.17.171

S. Djambazov, A. Yoleva, P. Chervenliev, A. Georgiev, J. Chem. Technol. Metall. 50, 520–524 (2015)

J. Klett, L. Klett, J. Kaufman, U.S. Pat. 7,456,131, Nov. 25, (2008)

L. Borchardt, N.L. Michels, T. Nowak, S. Mitchell, J. Pérez-Ramírez, Microporous Mesoporous Mater. (2015). https://doi.org/10.1016/j.micromeso.2015.01.028

P.F. Ahmadi, A. Ardeshir, A.M. Ramezanianpour, Ceram Int. (2018). https://doi.org/10.1016/j.ceramint.2018.01.175

Funding

The financial support was provided by the Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (2018R1D1A1B07042558).

Author information

Authors and Affiliations

Contributions

SR: conceptualization, methodology, data curation, formal analysis, writing—original draft. ESK: operation—micromeritics instrument (BET). Y-WK: conceptualization, methodology, supervision, resources, writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Rajpoot, S., Kang, E.S. & Kim, YW. Processing and properties of water-absorbing zeolite-based porous ceramics. J. Korean Ceram. Soc. 59, 94–103 (2022). https://doi.org/10.1007/s43207-021-00160-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43207-021-00160-2