Abstract

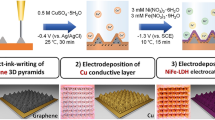

The electrochemical approach for the feasible ammonia production via N2 fixation is well-thought-out to be an eco-friendly strategy to replace the polluting Haber Bosch process. However, the impeding activation barrier of strong N≡N and the competing hydrogen evolution reaction constrain the Faradaic efficiency of the electrochemical nitrogen reduction reaction. Therefore, the implication of innovative strategies for designing an active electrocatalyst remains a crucial criterion to deliver operational efficiencies during electrochemical reactions. This study proposes a unique fabrication of three-dimensional (3D)-architectured electrodes encompassed with cobalt-rich tungsten carbide (Co-WC) as an electrocatalyst using a 3D-printing technique for the efficient electrochemical nitrogen reduction reaction. Here, the cobalt acts as a binder between tungsten carbide particles after sintering, and the particles are bonded to each other. The 3D-printing process generates 3D-architectured Co-WC electrodes with an average particle size of 1–3 µm through precise control of printing parameters. The electrochemical performance of the 3D-architectured Co-WC electrode reveals a better selectivity for N2 reduction under ambient condition. Substantially, the 3D-architectured Co-WC electrodes demonstrate an improved ammonia yield rate of 34.61 μg h−1 cm−2 and Faradaic efficiency of 2.12% at an applied potential − 0.6 V (vs. RHE). 3D-printing techniques can be an effective design method for manufacturing 3D-architectured active material with superior performance and selectivity.

Similar content being viewed by others

References

Y. Wang, D.F.R. Diaz, K.S. Chen, Z. Wang, X.C. Adroher, Materials, technological status, and fundamentals of PEM fuel cells–a review. Mater. Today 32, 178–203 (2020)

Y. Shao, J.P. Dodelet, G. Wu, P. Zelenay, PGM-free cathode catalysts for PEM fuel cells: a mini-review on stability challenges. Adv. Mater. 31, 1807615 (2019)

P.M. Bulemo, I.-D. Kim, Recent advances in ABO 3 perovskites: their gas-sensing performance as resistive-type gas sensors. J. Korean Ceram. Soc. 57, 24–39 (2020)

H.F. Wang, C. Tang, Q. Zhang, A review of precious-metal-free bifunctional oxygen electrocatalysts: rational design and applications in Zn− air batteries. Adv. Func. Mater. 28, 1803329 (2018)

S. Woo, H. Cho, J. Kim, Y. Lee, S. Lee, Microwave synthesis of MWCNT-supported PtRuNi catalysts and their electrocatalytic activity for direct methanol fuel cells. J. Korean Ceram. Soc. 57, 192–199 (2020)

G. Janani, Y. Chae, S. Surendran, Y. Sim, W. Park, J.K. Kim, U. Sim, Rational design of spinel oxide nanocomposites with tailored electrochemical oxygen evolution and reduction reactions for zincair batteries. Appl. Sci. 10, 3165 (2020)

Y. Sim, S.J. Kim, G. Janani, Y. Chae, S. Surendran, H. Kim, S. Yoo, D.C. Seok, Y.H. Jung, C. Jeon, The synergistic effect of nitrogen and fluorine co-doping in graphene quantum dot catalysts for full water splitting and supercapacitor. Appl. Surf. Sci. 507, 145157 (2020)

M. Peddigari, H. Palneedi, G.-T. Hwang, J. Ryu, Linear and nonlinear dielectric ceramics for high-power energy storage capacitor applications. J. Korean Ceram. Soc. 56, 1–23 (2019)

Y. Li, H. Wang, C. Priest, S. Li, P. Xu, G. Wu, Advanced electrocatalysis for energy and environmental sustainability via water and nitrogen reactions. Adv. Mater. 33, 2000381 (2021)

Y. Li, Z. Yin, X. Liu, M. Cui, S. Chen, T. Ma, Current progress of molybdenum carbide-based materials for electrocatalysis: potential electrocatalysts with diverse applications. Mater. Today Chem. 19, 100411 (2021)

D. Liu, M. Chen, X. Du, H. Ai, K.H. Lo, S. Wang, S. Chen, G. Xing, X. Wang, H. Pan, Development of electrocatalysts for efficient nitrogen reduction reaction under ambient condition. Adv. Func. Mater. 31, 2008983 (2021)

D.K. Yesudoss, G. Lee, S. Shanmugam, Strong catalyst support interactions in defect-rich γ-Mo2N nanoparticles loaded 2D-h-BN hybrid for highly selective nitrogen reduction reaction. Appl. Catal. B: Environ. 287, 119952 (2021)

F. Haber, R.L. Rossignol, The production of synthetic ammonia. Ind. Eng. Chem. 5, 328–331 (1913)

G. Duan, Y. Chen, Y. Tang, K.A.M. Gasem, P. Wan, D. Ding, M. Fan, Advances in electrocatalytic ammonia synthesis under mild conditions. Progress Energy Combust. Sci. 81, 100860 (2020)

J. Hou, M. Yang, J. Zhang, Recent advances in catalysts, electrolytes and electrode engineering for the nitrogen reduction reaction under ambient conditions. Nanoscale 12, 6900–6920 (2020)

J. John, D.-K. Lee, U. Sim, Photocatalytic and electrocatalytic approaches towards atmospheric nitrogen reduction to ammonia under ambient conditions. Nano Convergence 6, 1–16 (2019)

J.R. McKone, B.F. Sadtler, C.A. Werlang, N.S. Lewis, H.B. Gray, Ni–Mo nanopowders for efficient electrochemical hydrogen evolution. ACS Catal. 3, 166–169 (2013)

D.S. Patil, S.A. Pawar, J.C. Shin, Alteration of Ag nanowires to Ag/Ag2S nanowires@ CdS core-shell architectures for electrochemical supercapacitors. J. Alloy. Compd. 768, 1076–1082 (2018)

C. Wang, X.-G. Nie, Y. Shi, Y. Zhou, J.-J. Xu, X.-H. Xia, H.-Y. Chen, Direct plasmon-accelerated electrochemical reaction on gold nanoparticles. ACS Nano 11, 5897–5905 (2017)

S. Surendran, S. Shanmugapriya, Y.S. Lee, U. Sim, R.K. Selvan, Carbon-enriched cobalt phosphide with assorted nanostructure as a multifunctional electrode for energy conversion and storage devices. ChemistrySelect 3, 12303–12313 (2018)

Y.H. Kwok, A.C.H. Tsang, Y. Wang, D.Y.C. Leung, Ultra-fine Pt nanoparticles on graphene aerogel as a porous electrode with high stability for microfluidic methanol fuel cell. J. Power Sources 349, 75–83 (2017)

J.-H. Park, S.-D. Yim, T. Kim, S.-H. Park, Y.-G. Yoon, G.-G. Park, T.-H. Yang, E.-D. Park, Understanding the mechanism of membrane electrode assembly degradation by carbon corrosion by analyzing the microstructural changes in the cathode catalyst layers and polarization losses in proton exchange membrane fuel cell. Electrochim. Acta 83, 294–304 (2012)

P. Urchaga, T. Kadyk, S.G. Rinaldo, A.O. Pistono, J. Hu, W. Lee, C. Richards, M.H. Eikerling, C.A. Rice, Catalyst degradation in fuel cell electrodes: accelerated stress tests and model-based analysis. Electrochim. Acta 176, 1500–1510 (2015)

H. Yu, Z. Wang, S. Yin, C. Li, Y. Xu, X. Li, L. Wang, H. Wang, Mesoporous Au3Pd film on Ni foam: A self-supported electrocatalyst for efficient synthesis of ammonia. ACS Appl. Mater. Interfaces. 12, 436–442 (2019)

J. Zhang, Y. Wang, C. Zhang, H. Gao, L. Lv, L. Han, Z. Zhang, Self-supported porous NiSe2 nanowrinkles as efficient bifunctional electrocatalysts for overall water splitting. ACS Sustain. Chem. Eng. 6, 2231–2239 (2018)

C. Yu, F. Xu, L. Luo, H.S. Abbo, S.J.J. Titinchi, P.K. Shen, P. Tsiakaras, S. Yin, Bimetallic Ni-Co phosphide nanosheets self-supported on nickel foam as high-performance electrocatalyst for hydrogen evolution reaction. Electrochim. Acta 317, 191–198 (2019)

H. Yang, Z. Feng, X. Teng, L. Guan, H. Hu, M. Wu, Three-dimensional printing of high-mass loading electrodes for energy storage applications. InfoMat 3, 631 (2021)

J.-H. Park, J.-H. Lee, D.J. Kim, K.-T. Hwang, J.-H. Kim, K.-S. Han, Ink-jet 3D printability of ceramic ink with contact angle control. J. Korean Ceram. Soc. 56, 461–467 (2019)

K. Kim, A.P. Tiwari, T.G. Novak, S. Jeon, 3D ordered nanoelectrodes for energy conversion applications: thermoelectric, piezoelectric, and electrocatalytic applications. J. Korean Ceram. Soc 58, 379–398 (2021)

H.E. Exner, J. Gurland, A review of parameters influencing some mechanical properties of tungsten carbide–cobalt alloys. Powder Metall. 13, 13–31 (1970)

A.S. Kurlov, A.I. Gusev, Tungsten carbides. Springer Ser. Mater. Sci 184, 34–36 (2013)

L. Song, T. Wang, Y. Wang, H. Xue, X. Fan, H. Guo, W. Xia, H. Gong, J. He, Porous iron-tungsten carbide electrocatalyst with high activity and stability toward oxygen reduction reaction: from the self-assisted synthetic mechanism to its active-species probing. ACS Appl. Mater. Interfaces. 9, 3713–3722 (2017)

H. Huang, F. Li, Q. Xue, Y. Zhang, S. Yin, Y. Chen, Salt-templated construction of ultrathin cobalt doped iron thiophosphite nanosheets toward electrochemical ammonia synthesis. Small 15, 1903500 (2019)

L.F. Arenas, C.P. de León, F.C. Walsh, 3D-printed porous electrodes for advanced electrochemical flow reactors: a Ni/stainless steel electrode and its mass transport characteristics. Electrochem. Commun. 77, 133–137 (2017)

X. Huang, S. Chang, W.S.V. Lee, J. Ding, J.M. Xue, Three-dimensional printed cellular stainless steel as a high-activity catalytic electrode for oxygen evolution. J. Mater. Chem. A 5, 18176–18182 (2017)

J. Lölsberg, O. Starck, S. Stiefel, J. Hereijgers, T. Breugelmans, M. Wessling, 3D-printed electrodes with improved mass transport properties. ChemElectroChem 4, 3309–3313 (2017)

L.F. Arenas, C.P. De León, F.C. Walsh, Three-dimensional porous metal electrodes: Fabrication, characterisation and use. Curr. Opin. Electrochem. 16, 1–9 (2019)

M.-A. Porter, Effects of binder systems for metal injection moulding (2003)

M.K. Agarwala, R.V. Weeren, R. Vaidyanathan, A. Bandyopadhyay, G. Carrasquillo, V. Jamalabad, N. Langrana, A. Safari, S.H. Garofalini, S.C. Danforth, Structural ceramics by fused deposition of ceramics. In: International Solid Freeform Fabrication Symposium (1995)

M.A. Yardimci, S.I. Guceri, S.C. Danforth, Process Modeling for Fused Deposition of Ceramics (Wiley, New York, 1996), pp. 78–82

G. Wu, N.A. Langrana, S. Rangarajan, R. McCuiston, R. Sadanji, S.C. Danforth, A. Safari, Fabrication of metal components using FDMet: fused deposition of metals, In: Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, (1999), p. 775–782

J. Gonzalez-Gutierrez, S. Cano, S. Schuschnigg, C. Kukla, J. Sapkota, C. Holzer, Additive manufacturing of metallic and ceramic components by the material extrusion of highly-filled polymers: a review and future perspectives. Materials 11, 840 (2018)

S. Kumar, A. Czekanski, Optimization of parameters for SLS of WC-Co. Rapid Prototyp. J. 23, 1202 (2017)

S. Kumar, Process chain development for additive manufacturing of cemented carbide. J. Manuf. Process. 34, 121–130 (2018)

C.-W. Li, K.-C. Chang, A.-C. Yeh, On the microstructure and properties of an advanced cemented carbide system processed by selective laser melting. J. Alloy. Compd. 782, 440–450 (2019)

I. Fraunhofer, Droplet-based additive manufacturing of hard metal components by thermoplastic 3D printing (T3DP). J. Ceram. Sci. Technol. 8, 155–160 (2016)

K.-J. Jang, J.-H. Kang, J.G. Fisher, S.-W. Park, Effect of the volume fraction of zirconia suspensions on the microstructure and physical properties of products produced by additive manufacturing. Dent. Mater. 35, e97–e106 (2019)

R.K. Enneti, K.C. Prough, T.A. Wolfe, A. Klein, N. Studley, J.L. Trasorras, Sintering of WC-12% Co processed by binder jet 3D printing (BJ3DP) technology. Int. J. Refract Metal Hard Mater. 71, 28–35 (2018)

R.K. Enneti, K.C. Prough, Wear properties of sintered WC-12% Co processed via Binder Jet 3D Printing (BJ3DP). Int. J. Refract Metal Hard Mater. 78, 228–232 (2019)

J.A. Lewis, Binder removal from ceramics. Annu. Rev. Mater. Sci. 27, 147–173 (1997)

K.S. Hwang, Y.M. Hsieh, Comparative study of pore structure evolution during solvent and thermal debinding of powder injection molded parts. Metall. and Mater. Trans. A. 27, 245–253 (1996)

A.G.P. Da Silva, W.D. Schubert, B. Lux, The role of the binder phase in the WC-Co sintering. Mater. Res. 4, 59–62 (2001)

H.-W. Lee, H.-I. Ji, J.-H. Lee, B.-K. Kim, K.J. Yoon, J.-W. Son, Powder packing behavior and constrained sintering in powder processing of solid oxide fuel cells (SOFCs). J. Korean Ceram. Soc 56, 130–145 (2019)

J. Garcia, V.C. Cipres, A. Blomqvist, B. Kaplan, Cemented carbide microstructures: a review. Int. J. Refract Metal Hard Mater. 80, 40–68 (2019)

A. Moradkhani, H. Baharvandi, A. Naserifar, Effect of sintering temperature on the grain size and mechanical properties of Al2O3-SiC nanocomposites. J. Korean Ceram. Soc 56, 256–268 (2019)

P.L. Searle, The berthelot or indophenol reaction and its use in the analytical chemistry of nitrogen. A review, Analyst 109, 549–568 (1984)

Y. Moliner-Martínez, R. Herráez-Hernández, P. Campíns-Falcó, Improved detection limit for ammonium/ammonia achieved by berthelot’s reaction by use of solid-phase extraction coupled to diffuse reflectance spectroscopy. Anal. Chim. Acta 534, 327–334 (2005)

Funding

This work is supported by Creative Materials Discovery Program through the National Research Foundation of Korea (NRF-2016M3D1A1021141) and Chonnam National University (Grant Number: 2019-0217).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lee, DK., Wee, SJ., Jang, KJ. et al. 3D-printed cobalt-rich tungsten carbide hierarchical electrode for efficient electrochemical ammonia production. J. Korean Ceram. Soc. 58, 679–687 (2021). https://doi.org/10.1007/s43207-021-00142-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43207-021-00142-4