Abstract

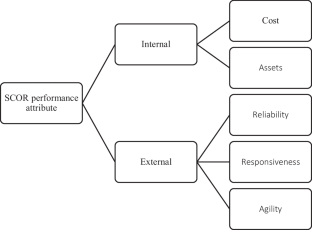

Performance measurement is critical for assessing the success of the supply chain. The supply chain operations reference (SCOR) model is one famous model used to measure supply chain performance. This study aims to identify gaps and provide future research directions using the SCOR for supply chain performance. Furthermore, this study proposed a conceptual framework that can be used as a guideline for real-life projects. This study was carried out in 2023 by reviewing previous articles that employed the SCOR model in supply chain performance between 2010 and 2022. The study applied the systematic mapping study processes to provide an overview of measuring supply chain performance using the SCOR model. This review disclosed that SCOR was a valuable management tool for measuring the performance of supply chains. It was one of the most commonly used models for assessing supply chain performance. The SCOR model has been used widely in different countries, industries, firms, and supply chains. Most of the previous studies worked with a case study and survey research. Level 1 of the SCOR metrics was employed the most. This review is the first attempt to investigate how the SCOR is used in supply chain performance measurement to the best of the author’s knowledge. Integrating emerging information technologies (such as blockchain, Internet of Things, artificial intelligence, and cloud computing) into the SCOR framework is a growing trend that drives the supply chain toward sustainability.

Similar content being viewed by others

Data Availability

The data that support the findings of this study are publicly available.

References

Alomar M, Pasek ZJ (2014) Linking supply chain strategy and processes to performance improvement. Procedia CIRP 17:628–634. https://doi.org/10.1016/j.procir.2014.01.144

Medini K, Rabénasolo B (2014) Analysis of the performance of supply chains configurations using multi-agent systems. Int J Log Res Appl 17(6):441–458. https://doi.org/10.1080/13675567.2014.894183

Reddy JMK, Neelakanteswara Rao A, Krishnanand L (2019b) A review on supply chain performance measurement systems. Procedia Manuf. https://doi.org/10.1016/j.promfg.2019.02.007

Kocaoǧlu B, Gülsün B, Tanyaş M (2013) A SCOR based approach for measuring a benchmarkable supply chain performance. J Intell Manuf 24(1):113–132. https://doi.org/10.1007/s10845-011-0547-z

Wibowo MA, Elizar SMN, Adji HS (2017) Supply chain management strategy for recycled materials to support sustainable construction. Procedia Eng 171:185–190. https://doi.org/10.1016/j.proeng.2017.01.325

Yadav S, Garg D, Luthra S (2021) Development of IoT based data-driven agriculture supply chain performance measurement framework. J Enterp Inf Manag 34(1):292–327. https://doi.org/10.1108/JEIM-11-2019-0369

Teixeira KC, Borsato M (2019) Development of a model for the dynamic formation of supplier networks. J Ind Inf Integr 15:161–173. https://doi.org/10.1016/j.jii.2018.11.007

Moharamkhani A, Bozorgi-Amiri A, Mina H (2017) Supply chain performance measurement using SCOR model based on interval-valued fuzzy TOPSIS. International Journal of Logistics Systems and Management 27(1):115–132. https://doi.org/10.1504/IJLSM.2017.083225

Ramaa A, Rangaswamy TM, Subramanya KN (2009) A review of literature on performance measurement of supply chain network. 2009 2nd International Conference on Emerging Trends in Engineering and Technology, ICETET 2009 802–807. https://doi.org/10.1109/ICETET.2009.18

Chorfi Z, Benabbou L, Berrado A (2018) An integrated performance measurement framework for enhancing public health care supply chains. Supply Chain Forum 19(3):191–203. https://doi.org/10.1080/16258312.2018.1465796

Bai C, Sarkis J (2012) Supply-chain performance-measurement system management using neighbourhood rough sets. Int J Prod Res 50(9):2484–2500. https://doi.org/10.1080/00207543.2011.581010

Estampe D, Lamouri S, Paris JL, Brahim-Djelloul S (2013) A framework for analysing supply chain performance evaluation models. Int J Prod Econ 142(2):247–258. https://doi.org/10.1016/j.ijpe.2010.11.024

Javed SA, Gunasekaran A, Mahmoudi A (2022) DGRA: Multi-sourcing and supplier classification through dynamic grey relational analysis method. Comp Indus Eng 173:108674. https://doi.org/10.1016/j.promfg.2019.02.007

Simão LE, Somensi K, Dávalos RV, Rodriguez CMT (2022) Measuring supply chain performance: the triple E model. Int J Product Perform Manag 71(7):2951–2969. https://doi.org/10.1108/IJPPM-06-2020-0291

Girjatovics A, Shekar SS, Kuznecova O, Pecerska J (2019) Simulation and SCOR: performance metrics integration to supply chain performance measurement. 2019 60th International Scientific Conference on Information Technology and Management Science of Riga Technical University (ITMS) 1–6. https://doi.org/10.1109/ITMS47855.2019.8940657

Bai C, Sarkis J, Wei X, Koh L (2012) Evaluating ecological sustainable performance measures for supply chain management. Supply Chain Manag 17(1):78–92. https://doi.org/10.1108/13598541211212221

Vlachos IP (2014) A hierarchical model of the impact of RFID practices on retail supply chain performance. Expert Syst Appl 41(1):5–15. https://doi.org/10.1016/j.eswa.2013.07.006

Piotrowicz W, Cuthbertson R (2015) Performance measurement and metrics in supply chains: an exploratory study. Int J Product Perform Manag 64(8):1068–1091

American Production and Inventory Control Society (2017) Supply chain operations reference model. In American Production and Inventory Control Society.

Delipinar GE, Kocaoglu B (2016) Using SCOR model to gain competitive advantage: a literature review. Procedia Soc Behav Sci 229:398–406. https://doi.org/10.1016/j.sbspro.2016.07.150

Srhir S, Jaegler A, Montoya-Torres JR (2023) Uncovering Industry 4.0 technology attributes in sustainable supply chain 4.0: a systematic literature review. Bus Strategy Environ 32(7):4143–4166. https://doi.org/10.1002/bse.3358

Lambert DM, Croxton KL (2005) An evaluation of process-oriented supply chain management frameworks 26(1):25–51

Cheng JCP, Law KH, Bjornsson H, Jones A, Sriram RD (2010) Modeling and monitoring of construction supply chains. Adv Eng Inform 24(4):435–455. https://doi.org/10.1016/j.aei.2010.06.009

Supply Chain Council (2012) Supply chain operations reference model. In Supply Chain Operations Management. https://doi.org/10.1108/09576059710815716

Reddy JMK, Neelakanteswara Rao A, Krishnanand L (2019) A review on supply chain performance measurement systems. Procedia Manuf 30:40–47. https://doi.org/10.1016/j.promfg.2019.02.007

Huan SH, Sheoran SK, Wan G (2004) A review and analysis of supply chain operations reference (SCOR) model. Supply Chain Manag 9(1):23–29. https://doi.org/10.1108/13598540410517557

Ntabe EN, LeBel L, Munson AD, Santa-Eulalia LA (2015) A systematic literature review of the supply chain operations reference (SCOR) model application with special attention to environmental issues. Int J Prod Econ 169:310–332. https://doi.org/10.1016/j.ijpe.2015.08.008

Petersen K, Vakkalanka S, Kuzniarz L (2015) Guidelines for conducting systematic mapping studies in software engineering: An update. Inf Softw Technol 64:1–18. https://doi.org/10.1016/j.infsof.2015.03.007

Nishikawa-Pacher A (2022) Who are the 100 largest scientific publishers by journal count? A webscraping approach Journal of Documentation 78(7):450–463. https://doi.org/10.1108/JD-04-2022-0083

Gayialis SP, Kechagias EP, Papadopoulos GA, Masouras D (2022) A review and classification framework of traceability approaches for identifying product supply chain counterfeiting. Sustainability (Switzerland). https://doi.org/10.3390/su14116666

Naz F, Agrawal R, Kumar A, Gunasekaran A, Majumdar A, Luthra S (2022) Reviewing the applications of artificial intelligence in sustainable supply chains: exploring research propositions for future directions. Bus Strateg Environ 31(5):2400–2423. https://doi.org/10.1002/bse.3034

Lima-Junior FR, Carpinetti LCR (2017) Quantitative models for supply chain performance evaluation: A literature review. Comput Ind Eng 113:333–346. https://doi.org/10.1016/j.cie.2017.09.022

Ayyildiz E, Taskin Gumus A (2021) Interval-valued Pythagorean fuzzy AHP method-based supply chain performance evaluation by a new extension of SCOR model: SCOR 4.0. Complex Intell Syst 7(1):559–576. https://doi.org/10.1007/s40747-020-00221-9

Ganga GMD, Carpinetti LCR (2011) A fuzzy logic approach to supply chain performance management. Int J Prod Econ 134(1):177–187. https://doi.org/10.1016/j.ijpe.2011.06.011

Li L, Su Q, Chen X (2011) Ensuring supply chain quality performance through applying the SCOR model. Int J Prod Res 49(1):33–57. https://doi.org/10.1080/00207543.2010.508934

Elgazzar SH, Tipi NS, Hubbard NJ, Leach DZ (2012) Linking supply chain processes’ performance to a company’s financial strategic objectives. Eur J Oper Res 223(1):276–289. https://doi.org/10.1016/j.ejor.2012.05.043

Lee KH, Ru T, Shiu YS, Sivakumar P (2012) The applications of SCOR in manufacturing: two cases in Taiwan. Procedia Engineering 38:2548–2563. https://doi.org/10.1016/j.proeng.2012.06.300

Cirtita H, Glaser-Segura DA (2012) Measuring downstream supply chain performance. J Manuf Technol Manag 23(3):299–314. https://doi.org/10.1108/17410381211217380

Sheppard A, Tatham P, Fisher R, Gapp R (2013) A SCOR framework to measure logistics performance of humanitarian organizations. J Humanit Logisti Supply Chain Manag 3(1):22–36. https://doi.org/10.1108/JHLSCM-11-2013-0041

Zhang W, Reimann M (2014) Towards a multi-objective performance assessment and optimization model of a two-echelon supply chain using SCOR metrics. Cent Eur J Oper Res 22(4):591–622. https://doi.org/10.1007/s10100-013-0294-7

Jothimani D, Sarmah SP (2014) Supply chain performance measurement for third party logistics. Benchmarking 21(6):944–963. https://doi.org/10.1108/BIJ-09-2012-0064

Bukhori IB, Widodo KH, Ismoyowati D (2015) Evaluation of poultry supply chain performance in XYZ Slaughtering House Yogyakarta using SCOR and AHP method. Agriculture and Agricultural Science Procedia 3:221–225. https://doi.org/10.1016/j.aaspro.2015.01.043

Wibowo MA, Sholeh MN (2015) The analysis of supply chain performance measurement at construction project. Procedia Eng 125:25–31. https://doi.org/10.1016/j.proeng.2015.11.005

Sellitto MA, Pereira GM, Borchardt M, Da Silva RI, Viegas CV (2015) A SCOR-based model for supply chain performance measurement: application in the footwear industry. Int J Prod Res 53(16):4917–4926. https://doi.org/10.1080/00207543.2015.1005251

Sangari MS, Hosnavi R, Zahedi MR (2015) The impact of knowledge management processes on supply chain performance: an empirical study. Int J Log Manag 26(3):603–626. https://doi.org/10.1108/IJLM-09-2012-0100

Okongwu U, Lauras M, François J, Deschamps JC (2016) Impact of the integration of tactical supply chain planning determinants on performance. J Manuf Syst 38:181–194. https://doi.org/10.1016/j.jmsy.2014.10.003

Liu FHF, Liu YC (2017) A methodology to assess the supply chain performance based on gap-based measures. Comput Ind Eng 110:550–559. https://doi.org/10.1016/j.cie.2017.06.010

Dissanayake CK, Cross JA (2018) Systematic mechanism for identifying the relative impact of supply chain performance areas on the overall supply chain performance using SCOR model and SEM. Int J Prod Econ 201:102–115. https://doi.org/10.1016/j.ijpe.2018.04.027

Akkawuttiwanich P, Yenradee P (2018) Fuzzy QFD approach for managing SCOR performance indicators. Comput Ind Eng 122(May):189–201. https://doi.org/10.1016/j.cie.2018.05.044

Moazzam M, Akhtar P, Garnevska E, Marr NE (2018) Measuring agri-food supply chain performance and risk through a new analytical framework: a case study of New Zealand dairy. Production Planning and Control 29(15):1258–1274. https://doi.org/10.1080/09537287.2018.1522847

Lima-Junior FR, Carpinetti LCR (2019) Predicting supply chain performance based on SCOR ® metrics and multilayer perceptron neural networks. Int J Prod Econ 212(January):19–38. https://doi.org/10.1016/j.ijpe.2019.02.001

Tripathi G, Ahad MA, Casalino G (2023) A comprehensive review of blockchain technology: underlying principles and historical background with future challenges. Decis Anal J 9:100344. https://doi.org/10.1016/j.dajour.2023.100344

Indrawati S, Sarinastiti N (2020) Green supply chain performance improvement through green SCOR in an Indonesian paper mill. 2020 6th International Conference on Science and Technology (ICST) 1:1–6. https://doi.org/10.1109/ICST50505.2020.9732884

Nguyen TTH, Bekrar A, Abed M, Le T (2021) Supply chain performance measurement using SCOR model: a case study of the coffee supply chain in Vietnam. 2021 1st International Conference On Cyber Management And Engineering (CyMaEn) 1–7. https://doi.org/10.1109/CyMaEn50288.2021.9497309

Zhou Y, Gao X, Nie J (2023) Value of blockchain‐enabled supply chain traceability under competition. International Transactions in Operational Research

Tripathi S, Talukder B, Rangarajan K (2021) Do supply chain performance influence firm profitability? A predictive approach in the context of the Indian pharmaceutical industry. IIM Kozhikode Soc Manag Rev 22779752211003452. https://doi.org/10.1177/22779752211003453

Gopal PRC, Rana NP, Krishna TV, Ramkumar M (2022) Impact of big data analytics on supply chain performance: an analysis of influencing factors. Ann Oper Res. https://doi.org/10.1007/s10479-022-04749-6

Wu M, Yang Z, Sun J, Gong X (2020) Addressing supply chain vulnerability by supporting emerging IT: an analysis based on SCOR framework. IEEE Int Confer Ind Eng Eng Manag (IEEM) 2020:576–580. https://doi.org/10.1109/IEEM45057.2020.9309844

Kamble SS, Gunasekaran A (2020) Big data-driven supply chain performance measurement system: a review and framework for implementation. Int J Prod Res 58(1):65–86. https://doi.org/10.1080/00207543.2019.1630770

Dvaipayana MAT, Ridwan AY, Santosa B (2021) Design of sustainable supply chain performance monitoring system for construction material management: sustainable balanced scorecard – SCOR – ISO 14001 model. 2021 International Conference Advancement in Data Science, E-Learning and Information Systems (ICADEIS), 1–6. https://doi.org/10.1109/ICADEIS52521.2021.9702023

Acknowledgements

This research is funded by University of Economics and Law, Vietnam National University Ho Chi Minh City, Vietnam.

Author information

Authors and Affiliations

Contributions

Conceptualization, T.T.H.N; methodology, T.T.H.N; validation, T.T.H.N ; writing—original draft preparation, T.T.H.N; writing—review and editing, T.T.H.N; visualization, T.T.H.N.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nguyen, T.T.H. Measuring Supply Chain Performance Using the SCOR Model. Oper. Res. Forum 5, 37 (2024). https://doi.org/10.1007/s43069-024-00314-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43069-024-00314-y