Abstract

Mechanistic pavement design procedures of flexible pavement based on elastic-layer theories require the determination or estimation of resilient modulus (MR) for each layer in the pavement structure. Considering the complexity and cost of testing required, regression models have been developed to predict resilient modulus of heavy-duty base crushed rock mixes from their physical and engineering properties. Testing results of MR for three different gradations of the same crushed rock with 15 different fines combinations of crusher dust (CD) and Claypro (CP) have been used to calibrate a universal three-parameter deviatoric stress model. The latter relates resilient modulus to both deviatoric and confining stresses and considers shear stresses and strains developed during loading. Physical properties of these mixes were then used to develop multiple linear regression models to predict the three parameters of the calibrated deviatoric stress model. The modelling process was repeated by including California bearing ratio as a predictor with the physical properties. Both sets of models show the properties considered herein, serve to explain a high variation in the three parameters, ranging between 71 and 91%. However, correlation between measured and predicted MR values from both sets of models is 0.90 and 0.87, respectively. Furthermore, the optimum clay content (CP) for the different mixtures was also assessed. The results indicated that 1% of CP can be considered the optimum content for all three gradations.

Similar content being viewed by others

References

Siswosoebrotho, B. I., Widodo, P., & Augusta, E. (2005). The influence of fines content and plasticity on the strength and permeability of aggregate for base course material. In: Proceedings of the Eastern Asia society for transportation studies, vol. 5, pp. 845–856.

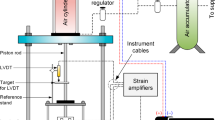

AASHTO, T. (2003). 307–99 Standard method of test for determining the resilient modulus of soils and aggregates. Washington: American Association of State Highway and Transportation Officials.

Seed, H. B., Chan, C., & Lee, C. E. (1962). Resilience characteristics of subgrade soils and their relation to fatigue failures in asphalt pavements. In: International conference on the structural design of asphalt pavements. Ann Arbor: Supplement University of Michigan.

Seed, H., Mitry, F., Monismith, C., & Chan, C. (1967). Prediction of flexible pavement deflections from laboratory repeated-load tests. NCHRP Report, 35.

Hicks, R. G., & Monismith, C. L. (1971). Factors influencing the resilient response of granular materials. Highway Research Record, 345, 15–31.

Allen, J. J. (1973). The effects of non-constant lateral pressure on the resilient response of granular materials. University of Illinois at Urbana-Champaign.

Cary, C. E., & Zapata, C. E. (2011). Resilient modulus for unsaturated unbound materials. Road Materials and Pavement Design, 12(3), 615–638.

Stolle, D., Guo, P., & Liu, Y. (2009). Resilient modulus properties of granular highway materials. Canadian Journal of Civil Engineering, 36(4), 639–654.

Levenberg, E., & Rocchi, I. (2020). On the thermal sensitivity of unbound granular pavement layers. International Journal of Pavement Research and Technology, 13(1), 32–39.

Nazzal, M. D., & Mohammad, L. N. (2010). Estimation of resilient modulus of subgrade soils for design of pavement structures. Journal of Materials in Civil Engineering, 22(7), 726–734.

Malla, R. B., & Joshi, S. (2007). Resilient modulus prediction models based on analysis of LTPP data for subgrade soils and experimental verification. Journal of Transportation Engineering, 133(9), 491–504.

Drumm, E., Boateng-Poku, Y., & Johnson Pierce, T. (1990). Estimation of subgrade resilient modulus from standard tests. Journal of Geotechnical Engineering, 116(5), 774–789.

Carmichael III, R., & Stuart, E. (1985). Predicting resilient modulus: A study to determine the mechanical properties of subgrade soils (abridgment). Transportation Research Record.

Von Quintus, H., & Killingsworth, B. (1998). Analysis relating to pavement material characterizations and their effects on pavement performance. Turner-Fairbank Highway Research Center.

Zaman, M., Laguros, J. G., Tian, P., Zhu, J., & Pandey, K. K. (1998). Resilient moduli of raw and stabilized aggregate bases and evaluation of layer coefficients for AASHTO flexible pavement design volume, Volume 1. School of Civil Engineering and Environmental Science The University of Oklahoma.

Dione, A., Fall, M., Berthaud, Y., Benboudjama, F., & Michou, A. (2014). Implementation of resilient modulus–CBR relationship in mechanistic pavement design. Sciences Appliquées et de l’Ingénieur, 1(2), 65–71.

Angell, D. J. (1988). Technical basis for pavement design manual. Brisbane, Queensland: Main Roads Department.

Sukumaran, B., Kyatham, V., Shah, A., & Sheth, D. (2002). Suitability of using california bearing ratio test to predict resilient modulus. In Proceedings: Federal aviation administration airport technology transfer conference (p. 9).

Santha, B. (1994). Resilient modulus of subgrade soils: Comparison of two constitutive equations. Transportation Research Record, 1462, 79–90.

Barksdale, R. D. (1991). The aggregate handbook. Washington, D.C: National Stone Association.

Tutumluer, E., Mishra, D., & Butt, A. A. (2009). Characterization of Illinois aggregates for subgrade replacement and subbase. Illinois Center for Transportation.

Salam, S., Osouli, A., & Tutumluer, E. (2018). Crushed limestone aggregate strength influenced by gradation, fines content, and dust ratio. Journal of Transportation Engineering, Part B: Pavements, 144(1), 04018002.

Seitllari, A., Lanotte, M., & Kutay, M. E. (2020). Effect of aggregate selection and design gyrations on the performance of polymer and devulcanized rubber modified mixtures. International Journal of Pavement Research and Technology, 14, 1–9.

Beriha, B., & Sahoo, U. C. (2020). Analysis of flexible pavement with cross-anisotropic material properties. International Journal of Pavement Research and Technology, 13(4), 411–416.

Kamal, M., Dawson, A., Farouki, O., Hughes, D., & Sha’at, A. (1993). Field and laboratory evaluation of the mechanical behavior of unbound granular materials in pavements. Transportation Research Record, p. 88–97.

Osouli, A., Salam, S., & Tutumluer, E. (2016). Effect of plasticity index and dust ratio on moisture-density and strength characteristics of aggregates. Transportation Geotechnics, 9, 69–79.

Osouli, A., Chaulagai, R., Tutumluer, E., & Shoup, H. (2019). Strength characteristics of crushed gravel and limestone aggregates with up to 12% plastic fines evaluated for pavement base/subbase applications. Transportation Geotechnics, 18, 25–38.

Aboutalebi Esfahani, M., & Goli, A. (2018). Effects of aggregate gradation on resilient modulus and CBR in unbound granular materials. International Journal of Transportation Engineering, 5(4), 367–381.

Rada, G., & Witczak, M. W. (1981). Comprehensive evaluation of laboratory resilient moduli results for granular material. Transport Research Record, 810, 23–33.

Zeghal, M. (2000). Variability of resilient moduli of aggregate materials due to different gradations. In Canadian society for civil engineering annual conference. (pp. 363–367) NRC Institute for Research in Construction, National Research Council Canada.

Tian, P., Zaman, M. M., & Laguros, J. G. (1998). Gradation and moisture effects on resilient moduli of aggregate bases. Transportation Research Record, 1619(1), 75–84.

Tian, P., Zaman, M. M., & Laguros, J. G. (1998). Variation of resilient modulus of aggregate base and its influence on pavement performance. Journal of Testing and Evaluation, 26(4), 329–335.

Zaman, M., Chen, D.-H., & Laguros, J. (1994). Resilient moduli of granular materials. Journal of Transportation Engineering, 120(6), 967–988.

Lekarp, F., Isacsson, U., & Dawson, A. (2000). State of the art. I: Resilient response of unbound aggregates. Journal of transportation engineering, 126(1), 66–75.

Barksdale, R. (1984). Performance of crushed-stone base courses. Transporation research record. (Vol. 954). Washington: Transportation Research Board.

Barskale, R. D., & Itani, S. Y. (1989). Influence of aggregate shape on base behavior. Transportation Research Record, p. 173–182.

Mishra, D., & Tutumluer, E. (2012). Aggregate physical properties affecting modulus and deformation characteristics of unsurfaced pavements. Journal of Materials in Civil Engineering, 24(9), 1144–1152. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000498.

Osouli, A., Adhikari, P., Tutumluer, E., & Shoup, H. (2019). Properties of aggregate fines influencing modulus and deformation behaviour of unbound aggregates. International Journal of Pavement Engineering, 22, 1–16.

Mishra, D., Tutumluer, E., & Butt, A. (2010). Quantifying effects of particle shape and type and amount of fines on unbound aggregate performance through controlled gradation. Transportation Research Record: Journal of the Transportation Research Board, 2167, 61–71.

Vuong, B., Jameson, G., Sharp, K. G., & Fielding, B. (2008). Guide to pavement technology part 4A: Granular base and subbase materials. Austroads, No. AGPT04A/08.

VicRoads. (2017). Registration of crushed rock mixes, Code of Practice RC 500.02. Melbourne: VicRoads.

AS 1289.3.2.1 (2009). Methods of testing soils for engineering purposes Method 3.2.1: Soil classification tests—Determination of the plastic limit of a soil—Standard method. Sydney, Australia: Australian Standard.

AS 1289.3.9.1 (2015). Methods of testing soils for engineering purposes Method 3.9.1: Soil calssification tests—Determination of the cone liquid limit of a soil. Sydney, Australia: Australian Standard.

AS 1289.3.1 (2009). Methods of testing soils for engineering purposes Method 3.1.1—Soil classification tests—Determination of the liquid limit of a soil—Four point Casagrande method. Sydney, Australia: Australian Standard.

AS 1289.3.3.1 (2009). Methods of testing soils for engineering purposes Method 3.3.1: Soil classification tests—Calculation of the plasticity index of a soil. Sydney, Australia: Australian Standard.

AS 1289.5.2.1 (2017). Methods of testing soils for engineering purposes Method 5.2.1: Soil compaction and density tests—Determination of the dry density/moisture content relation of a soil using modified compactive effort. Sydney, Australia: Australian Standard.

AS 1289.6.1.1 (2014). Methods of testing soils for engineering purposes Method 6.1.1: Soil strength and consolidation tests—Determination of the California Bearing Ratio of a soil—Standard laboratory method for a remoulded specimen. Sydney, Australia: Australian Standard.

AASHTO. (2007). Determining the resilient modulus of soils and aggregate materials. Washington, D.C.: AASHTO designation T 307-99.

VicRoads (2010). Best practice for the preparation of new granular pavements for thin bituminous surfacing. Melbourne: VicRoads

Austroads. (2019). Guide to pavement technology Part 4D: Stabilised materials. Sydney, Australia: Austroad.

Georgees, R. N., Hassan, R. A., Evans, R. P., & Jegatheesan, P. (2018). Resilient response characterization of pavement foundation materials using a polyacrylamide-based stabilizer. Journal of Materials in Civil Engineering, 30(1), 04017252.

Puppala, A. J., Mohammad, L. N., & Allen, A. (1996). Engineering behavior of lime-treated Louisiana subgrade soil. Transportation Research Record, 1546(1), 24–31.

Acknowledgements

The first author gratefully acknowledges the joint scholarship support provided to by the Iraqi Ministry of Higher Education and Scientific Research and the Swinburne University. The authors gratefully acknowledge the support provided by the road and traffic authority of Victoria/Australia (VicRoads) for this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fouad, A., Hassan, R. & Mahmood, A. Developing Resilient Modulus Prediction Models Based on Experimental Results of Crushed Hornfels Mixes with Different Gradations and Plasticity. Int. J. Pavement Res. Technol. 15, 124–137 (2022). https://doi.org/10.1007/s42947-021-00005-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42947-021-00005-5