Abstract

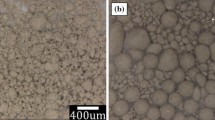

The cermet fuel element was achieved by dispersing the UO2 particles with or without tungsten (W) coating layer uniformly in the W matrix. It is considered to be a robust and secure fuel for use in nuclear thermal propulsion in the near future. In this study, the effect of deposition temperature on the densification and grain refinement of the W coating layer was investigated. A high-density (19.24 g·cm−3) W layer with a uniform thickness (~ 10 μm) and fine grains (~ 297 nm) was prepared by spouted-bed chemical vapor deposition. The prepared high-density, fine-grained W layer has the following advantages. It can prevent direct contact between fuel particles, resulting in a more uniform fuel distribution. In addition, it can decrease the reaction probability between the fuel kernel and H2, and prevent the release of fission products from the fuel kernel by extending the diffusion path at grain boundaries more efficiently. Moreover, the high-density, fine-grained W layer showed outstanding thermal and mechanical performance. Its average hardness and Young’s modulus were approximately 7 and 200 GPa, respectively. The thermal conductivity of the W film was 101–124 W·m−1·K−1 at 298–773 K. This work furthers our understanding of the potential application of the high-density, fine-grained W layer in nuclear thermal propulsion.

Similar content being viewed by others

References

Ji Y, Liu Z, Sun J, Shi L. Analysis of the flow distribution in a particle bed reactor for nuclear thermal propulsion. Energies. 2019;12(19):3590.

Houts M, Mitchell S. Development and Utilization of Nuclear Thermal Propulsion. Tech Rep. 2016.

Gabrielli R, Herdrich G. Review of nuclear thermal propulsion systems. Prog Aerosp Sci. 2015;79:92.

Borowski S, McCurdy D, Packard T. Nuclear Thermal Propulsion (NPT): A Proven, Growth Technology for “Fast Transit” Human Missions to Mars. AIAA SPACE 2013 Conference and Exposition, Ohio, 2013.

Tuckers D, Connor A, Hickman R. A methodology for producing uniform distribution of UO2 in a Tungsten matrix. J Phys Sci Appl. 2015;5(4):255.

Czysz P, Bruno C. Future spacecraft propulsion systems. 2nd ed. Chichester: Praxis Publishing; 2009. p. 574.

Haertling C, Hanrahan R. Literature review of thermal and radiation performance parameters for high-temperature, uranium dioxide fueled cermet materials. J Nucl Mater. 2007;366(3):317.

Bhattacharyya S. An assessment of fuels for Nuclear Thermal Propulsion. Tech. Rep. 2001.

Sessim M, Tonks M. Multiscale simulations of thermal transport in W-UO2 CERMET Fuel for nuclear thermal propulsion. Nucl Technol. 2021;207(7):1.

Burkers D, Wachs D, Werner J, Howe S. An Overview of Current and Past W-UO2 CERMET Fuel Fabrication Technology. Proceedings of Space Nuclear Conference, Boston, 2007.

Cowan C, Palmer R, Hoomissen J, Bhattacharyya S. CERMET fuel reactors. Boston: ASME Meeting; 1987.

Marlowe M, Kaznoff A. Development of low thermal expansion Tungsten-UO2 CERMET fuel. Tech. Rep. 1970.

Brengle R, Harty R, Bhattacharyya S. The promise and challenges of cermet fueled nuclear thermal propulsion reactors. AIAA/ SAE/ ASME/ASEE 29th Joint Propulsion Conference and Exhibit, Monterey, 1993.

Hickman R, Broadway J, Mireles O. Fabrication and Testing of CERMET Fuel Materials for Nuclear Thermal Propulsion. AIAA/ASME/SAE/ASEE Joint Propulsion Conference, Atlanta, 2012.

Tucker D, Wu Y, Burns J. Uranium migration in spark plasma sintered W/UO2 CERMETS. J Nucl Mater. 2018;500:141.

Webb J, Charit I. Fabrication of cermets via spark-plasma sintering for nuclear applications. J Miner Metals Mater Soc. 2014;66(6):943.

Obrien R, Jerred N. Spark plasma sintering of W-UO2 cermets. J Nucl Mater. 2013;443:50.

Broadway J, Hickman R, Mireles O. The Manufacture of W-UO2 Fuel Elements for Nuclear Thermal Propulsion Using the Hot Isostatic Pressing Consolidation Process. Nuclear and Emerging Technologies for Space. Tech Rep. 2012.

Hickman R, Panda B, Shah S. Fabrication of High Temperature Cermet Materials for Nuclear Thermal Propulsion. 53rd JANNAF Propulsion Meeting, Alabama, 2005.

Li C, Wang B, Zhang Z, Zhang L. Erosion of tungsten surfaces in He and Ar/He plasma. Nucl Sci Tech. 2016;27:37.

Zhang S, Nie Y, Ren J, Luo F, Ruan X, Chen Z, Han R, Bao T, Ge S. Benchmarking of JEFF-3.2, FENDL-3.0, and TENDL-2014 evaluated data for tungsten with 14.8 MeV neutrons. Nuclear Sci Tech. 2017;28:27.

Tucker D, Barnes M, Hone L, Cook S. High density, uniformly distributed W/UO2 for use in Nuclear Thermal Propulsion. J Nucl Mater. 2017;486:246.

Kruger G. A cermet fuel reactor for nuclear thermal propulsion. Tech Rep. 1991.

Barnes M. An Overview of CERMET Fuel Development at Marshall Space Flight Center. Tech Rep. 2017.

Sikora F, Millunzi A. Hot isostatic compaction of tungsten-uranium dioxide fuels with high-volume fraction of uranium dioxide. Tech Rep. 1968.

Huang H, Wu Y, Wang S, He Y, Zou J, Huang B, Liu C. Mechanical properties of single crystal tungsten microwhiskers characterized by nanoindentation. Mater Sci Eng A. 2009;523:193.

Lian Y, Liu X, Wang J, Feng F, Lv Y, Song J, Chen J. Influence of surface morphology and microstructure on performance of CVD tungsten coating under fusion transient thermal loads. Appl Surf Sci. 2016;390:167.

Lv Y, Song J, Lian Y, Yu Y, Liu X, Zhuang Z. The thermal properties of high purity and fully dense tungsten produced by chemical vapor deposition. J Nucl Mater. 2015;457:317.

Liu Q, Zhang L, Cheng L. Low pressure chemical vapor deposition of niobium coatings on graphite. Vacuum. 2010;85:332.

Murphy J, Giannattasio A, Yao Z, Hetherington C, Nellist P, Roberts S. The mechanical properties of tungsten grown by chemical vapour deposition. J Nucl Mater. 2009;388:583.

Hou L, Wang S, Chen G, He Y, Xie Y. Mechanical properties of tungsten nanowhiskers characterized by nanoindentation. Trans Nonferrous Metals Soc China. 2013;23:2323.

Oliver W, Pharr G. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res. 2011;6:1564.

Hickman R, Broadway J. Hot Hydrogen Testing of Tungsten-Uranium Dioxide (W-UO2) CERMET Fuel Materials for Nuclear Thermal Propulsion. Nuclear and Emerging Technologies for Space Conference, Huntsville, 2014.

Acknowledgements

This work was financially supported by the Thorium Molten Salt Reactor Nuclear Energy System under the Strategic Pioneer Sci. & Tech. Project of the Chinese Academy of Sciences (XDA02030200), the Frontier Science Key Program of the Chinese Academy of Sciences (Grant No. QYZDY-SSW-JSC016), the Natural Science Foundation of Shanghai (Grant No. 20ZR1468800 and 21ZR1476300), the Natural Science Foundation of Gansu province (Grant No. 20JR5RE639), and the Shanghai Pujiang Program (Grant No. 19pj1431600).

Author information

Authors and Affiliations

Contributions

Li-Hua Guo and Feng Zhang performed the experiments under the guidance of Jun Lin; Jun Lin, Yan You, Jun-Qiang Lu and Li-Bing Zhu provided financial support. All authors discussed and contributed to the writing and revisions.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Guo, LH., Zhang, F., Lu, LY. et al. Preparation of the highly dense ceramic–metal fuel particle with fine-grained tungsten layer by chemical vapor deposition for the application in nuclear thermal propulsion. Tungsten 4, 1–9 (2022). https://doi.org/10.1007/s42864-021-00117-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42864-021-00117-2