Abstract

Purpose

The industrial application of pectin is increasing although its production was far away from the demand, which exerts extra pressure on the existing pectin sources. The present study was focused on the extraction and quality evaluation of pectin from Citrus sinensis (sweet orange) peel as a potential pectin source.

Methodology

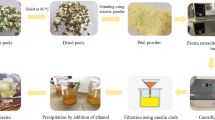

Pectin was extracted from sweet orange peel powder in a shaking water bath at three different extraction conditions, viz. temperatures (65, 75, 85, and 95 °C), pH (1.0, 1.5, 2, and 2.5), and time (45, 60, 75, and 90 min). The extracted pectin was dried to constant weight in a cabinet dryer at 50 °C and packed in the high-density polyethylene pouch and stored at 4 °C until used for quality analysis. After single factor experiments, optimization of process variables was done statistically using the response surface methodology (RSM), where the experimental data were fitted to a second-order polynomial model.

Results

The pectin yield was found to vary between 12.52 and 22.45% and the best extraction condition was recorded to be higher in yield at the temperature of 95 °C (21.53%), pH of 1.5 (21.28%), and extraction time of 90 min (22.45%) from the single factor optimization. The quality parameters of pectin, e.g., equivalent weight (1744.66~1899.33 g), methoxyl group content (5.02~5.64%), and degree of esterification (73.26~77.56%), were found to be in satisfactory levels. On the contrary, anhydrouronic acid content (38.47~41.30%) was very low compared to the existing data for various pectin sources. The developed polynomial model has effectively explained the data variation and adequately described the actual correlation between the independent and dependent variables. Results from both single factor experiments and RSM revealed that extraction temperature, pH, and time had a significant influence on the yield and quality of the extracted pectin. From the optimization study, the optimum condition was found as the temperature of 94.13 °C, pH of 1.45, and time of 114.70 min, which yielded 23.64% pectin.

Conclusion

Conclusively, extraction of pectin from sweet orange peel could be of great interest for application in the food and pharmaceutical industries.

Similar content being viewed by others

References

Acar, Ü., Kesbiç, O. S., Yılmaz, S., Gültepe, N., & Türker, A. (2015). Evaluation of the effects of essential oil extracted from sweet orange peel (Citrus sinensis) on growth rate of tilapia (Oreochromis mossambicus) and possible disease resistance against Streptococcus iniae. Aquaculture, 437, 282–286. https://doi.org/10.1016/j.aquaculture.2014.12.015.

Aina, V. O., Barau, M., Mamman, O. A., Zakari, A., Haruna, H., & Baba Abba, Y. (2012). Extraction and characterization of pectin from peels of lemon (Citrus limon), grape fruit (Citrus paradisi) and sweet orange (Citrus sinensis). British Journal of Pharmacology and Toxicology, 3, 259–262.

Azad, A. K. M., Ali, M. A., Akter, M. S., Rahman, J., & Ahmed, M. (2014). Isolation and characterization of pectin extracted from lemon pomace during ripening. Journal of Food and Nutrition Sciences, 2(2), 30–35. https://doi.org/10.11648/j.jfns.20140202.12.

Boukroufa, M., Boutekedjiret, C., & Chemat, F. (2017). Development of a green procedure of citrus fruits waste processing to recover carotenoids. Resource-Efficient Technologies, 3(3), 252–262. https://doi.org/10.1016/j.reffit.2017.08.007.

Chan, S. Y., & Choo, W. S. (2013). Effect of extraction conditions on the yield and chemical properties of pectin from cocoa husks. Food Chemistry, 141(4), 3752–3758. https://doi.org/10.1016/j.foodchem.2013.06.097.

de Oliveira, C. F., Giordani, D., Lutckemier, R., Gurak, P. D., Cladera-Olivera, F., & Marczak, L. D. F. (2016). Extraction of pectin from passion fruit peel assisted by ultrasound. LWT - Food Science and Technology, 71, 110–115. https://doi.org/10.1016/j.lwt.2016.03.027.

Fakayode, O. A., & Abobi, K. E. (2018). Optimization of oil and pectin extraction from orange (Citrus sinensis) peels: a response surface approach. Journal of Analytical Science and Technology, 9(20), 1–16. https://doi.org/10.1186/s40543-018-0151-3

Food Chemicals Codex. (1996). IV monographs. Washington, D.C.: National Academy Press. https://law.resource.org/pub/us/cfr/ibr/004/nas.food.1996.pdf.

Güzel, M., & Akpınar, Ö. (2019). Valorisation of fruit by-products: production characterization of pectins from fruit peels. Food and Bioproducts Processing, 115, 126–133. https://doi.org/10.1016/j.fbp.2019.03.009.

Hosseini, S. S., Khodaiyan, F., & Yarmand, M. S. (2016). Optimization of microwave assisted extraction of pectin from sour orange peel and its physicochemical properties. Carbohydrate Polymers, 140, 59–65. https://doi.org/10.1016/j.carbpol.2015.12.051.

Ismail, N. S. M., Ramli, N., Hani, N. M., & Meon, Z. (2012). Extraction and characterization of pectin from dragon fruit (Hylocereus polyrhizus) using various extraction conditions. Sains Malaysiana, 41(1), 41–45. https://doi.org/10.3303/CET1756135.

Jafari, F., Khodaiyan, F., Kiani, H., & Hosseini, S. S. (2017). Pectin from carrot pomace: optimization of extraction and physicochemical properties. Carbohydrate Polymers, 157, 1315–1322. https://doi.org/10.1016/j.carbpol.2016.11.013.

Kamal, M. M., Ali, M. R., Shishir, M. R. I., Saifullah, M., Haque, M. R., & Mondal, S. C. (2019). Optimization of process parameters for improved production of biomass protein from Aspergillus niger using banana peel as a substrate. Food Science and Biotechnology, 28(6), 1693–1702. https://doi.org/10.1007/s10068-019-00636-2.

Kamal, M. M., Ali, M. R., Hossain, A., & Shishir, M. R. I. (2020). Optimization of microwave-assisted extraction of pectin from Dillenia indica fruit and its preliminary characterization. Journal of Food Processing & Preservation, 44. https://doi.org/10.1111/jfpp.14466.

Korish, M. (2015). Potential utilization of Citrullus lanatus var. Colocynthoides waste as a novel source of pectin. Journal of Food Science and Technology, 52(4), 2401–2407. https://doi.org/10.1007/s13197-014-1277-y.

Kulkarni, S. G., & Vijayanand, P. (2010). Effect of extraction conditions on the quality characteristics of pectin from passion fruit peel (Passiflora edulis f. flavicarpa L.). LWT - Food Science and Technology, 43(7), 1026–1031. https://doi.org/10.1016/j.lwt.2009.11.006.

Kumar, A., & Chauhan, G. S. (2010). Extraction and characterization of pectin from apple pomace and its evaluation as lipase (steapsin) inhibitor. Carbohydrate Polymers, 82(2), 454–459. https://doi.org/10.1016/j.carbpol.2010.05.001.

Kumar, R., Chanalia, P., Gandhi, D., & Dhanda, S. (2016). Optimized extraction and characterization of pectin from gooseberry and strawberry pomace validated by response surface methodology. World Applied Sciences Journal, 34(6), 704–713. https://doi.org/10.5829/idosi.wasj.2016.34.6.30.

Lalnunthari, C., Devi, L. M., & Badwaik, L. S. (2019). Extraction of protein and pectin from pumpkin industry by- products and their utilization for developing edible film. Journal of Food Science and Technology, 57, 1807–1816. https://doi.org/10.1007/s13197-019-04214-6.

Lefsih, K., Giacomazza, D., Dahmoune, F., Mangione, M. R., Bulone, D., San Biagio, P. L., Passantino, R., Costa, M. A., Guarrasi, V., & Madani, K. (2017). Pectin from Opuntia ficus indica: optimization of microwave-assisted extraction and preliminary characterization. Food Chemistry, 221, 91–99. https://doi.org/10.1016/j.foodchem.2016.10.073.

Liew, S. Q., Chin, N. L., & Yusof, Y. A. (2014). Extraction and characterization of pectin from passion fruit peels. Agriculture and Agricultural Science Procedia, 2, 231–236. https://doi.org/10.1016/j.aaspro.2014.11.033.

Madhav, A., & Pushpalatha, P. B. (2002). Characterization of pectin extracted from different fruit wastes. Journal of Tropical Agriculture, 40, 53–55.

Maran, J. P., & Priya, B. (2015). Ultrasound-assisted extraction of pectin from sisal waste. Carbohydrate Polymers, 115, 732–738. https://doi.org/10.1016/j.carbpol.2014.07.058.

Maran, J. P., Sivakumar, V., Thirugnanasambandham, K., & Sridhar, R. (2013). Optimization of microwave assisted extraction of pectin from orange peel. Carbohydrate Polymers, 97(2), 703–709. https://doi.org/10.1016/j.carbpol.2013.05.052.

Maran, J. P., Swathi, K., Jeevitha, P., Jayalakshmi, J., & Ashvini, G. (2015). Microwave-assisted extraction of pectic polysaccharide from waste mango peel. Carbohydrate Polymers, 123, 67–71. https://doi.org/10.1016/j.carbpol.2014.11.072.

Mohamed, S., & Hasan, Z. (1995). Extraction and characterisation of pectin from various tropical agrowastes. ASEAN Food Journal, 10(2), 43–50.

Owens, H. (1952). Methods Used at Western Regional Research Laboratory for Extraction and Analysis of Pectic Materials Volume 340 of AIC series. Western Regional Research Laboratory, Albany, Calif, United States. Bureau of Agricultural and Industrial Chemistry. Western Regional Research Laboratory, Bureau of Agricultural and Industrial Chemistry, Agricultural Research Administration, U.S. Department of Agriculture (24 pp)

Prasanna, V., Prabha, T. N., & Tharanathan, R. N. (2007). Fruit ripening phenomena – an overview. Critical Reviews in Food Science and Nutrition, 47, 1–19. https://doi.org/10.1080/10408390600976841.

Ramli, N., & Asmawati. (2011). Effect of ammonium oxalate and acetic acid at several extraction time and pH on some physicochemical properties of pectin from cocoa husks (Theobroma cacao). African Journal of Food Science, 5(15), 790–798. https://doi.org/10.5897/AJFS11.107.

Ranganna, S. (1995). Handbook of analysis and quality control for fruit and vegetable products (Second). New Delhi: McGraw Hill publishing Co. Ltd.. (1112 pp)

Sawalha, S. M. S., Arráez-Román, D., Segura-Carretero, A., & Fernández-Gutiérrez, A. (2009). Quantification of main phenolic compounds in sweet and bitter orange peel using CE–MS/MS. Food Chemistry, 116(2), 567–574. https://doi.org/10.1016/j.foodchem.2009.03.003.

Shishir, M. R. I., Taip, F. S., Aziz, N. A., Talib, R. A., & Hossain Sarker, M. S. (2016). Optimization of spray drying parameters for pink guava powder using RSM. Food Science and Biotechnology, 25(2), 461–468. https://doi.org/10.1007/s10068-016-0064-0.

Sotanaphun, U., Chaidedgumjorn, A., Kitcharoen, N., Satiraphan, M., Asavapichayont, P., & Sriamornsak, P. (2012). Preparation of pectin from fruit peel of Citrus maxima. Silpakorn University Science and Technology Journal, 6(1), 42–48. https://doi.org/10.14456/sustj.2012.3

Sundar Raj, A. A., Rubila, S., Jayabalan, R., & Ranganathan, T. V. (2012). A review on pectin: chemistry due to general properties of pectin and its pharmaceutical uses. Open Access Scientific Reports, 1(12), 1–4. https://doi.org/10.4172/scientificreports.550.

Yadav, S. R., Khan, Z. H., Kunjwani, S. S., & Mular, S. M. (2015). Extraction and characterization of pectin from different fruits. International Journal of Applied Research, 1(9), 91–94. https://doi.org/10.3303/CET1544044.

Zhang, L., Ye, X., Xue, S. J., Zhang, X., Liu, D., Meng, R., & Chen, S. (2013). Effect of high-intensity ultrasound on the physicochemical properties and nanostructure of citrus pectin. Journal of the Science of Food and Agriculture, 93(8), 2028–2036. https://doi.org/10.1002/jsfa.6011.

Acknowledgments

Special notes of thanks to Professor Dr. Maruf Ahmed, Department of Food Processing and Preservation, HSTU, Dinajpur 5200, Bangladesh, for his cordial assistance.

Funding

This study was financially supported by the Institute of Research and Training (IRT) of Hajee Mohammad Danesh Science and Technology University (HSTU), Dinajpur 5200, Bangladesh.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Kamal, M.M., Kumar, J., Mamun, M.A.H. et al. Extraction and Characterization of Pectin from Citrus sinensis Peel. J. Biosyst. Eng. 46, 16–25 (2021). https://doi.org/10.1007/s42853-021-00084-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42853-021-00084-z