Abstract

Purpose

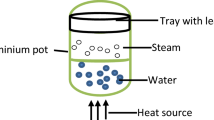

This study was conducted to develop and evaluate the effects of vacuum assisted solar drying on the quality attributes of crush, tear and curl (CTC) black tea.

Methods

The influence of process parameters on the quality of tea was analyzed by using Design expert 7.1.1 software. The independent parameters namely vacuum level and loading rate were varied as per rotatable central composite design, and the responses were liquor colour (LC), aroma index (AI), drying time (t) and energy consumption (EC).

Results

The optimum drying condition was successfully found to be at a vacuum level of 570.71 mmHg and loading rate of 0.96 kg dry solid m−2. The LC redness and yellowness index, AI, t and EC were found to be 20.08, 11.65, 4.44, 140.66 min and 21450.7 kJ respectively in optimized condition. Two individual catechin, namely EGCG (epigallocatechin gallate) and ECG (epigallocatechin); four individual theaflavin like total theaflavins (TF), TF3MG (theaflavin-3-monogallate), TF3’MG (theaflavin-3′-monogallate) and TF3,3’DG (theaflavin-3,3′-digallate) and caffeine were detected in the made tea at the optimized conditions.

Conclusions

The predicted optimum drying conditions were in good term with the experimental results obtained. This optimum input parameters obtained from the present study would help to produce quality tea.

Similar content being viewed by others

Abbreviations

- BOP:

-

broken orange pekoe

- CTC:

-

crush tear curl

- E:

-

energy consumption, kJ

- ECG:

-

epicatechin gallate

- EGCG:

-

epigallocatechin gallate

- I:

-

current supplied, A

- t:

-

drying time, min

- TF:

-

theaflavin

- TR:

-

thearubigin

- TF3MG:

-

theaflavin-3-monogallate

- TF3’MG:

-

theaflavin-3′-monogallate

- TF3, 3’DG:

-

theaflavin-3, 3′-digallate

- TV:

-

Tocklai vegetative

- V:

-

voltage supplied to the vacuum pump, V

References

Alam, M. S., Singh, A., & Sawhney, B. K. (2010). Response surface optimization of osmotic dehydration process for aonla slices. Journal of Food Science and Technology, 47, 47–54.

Baruah, A. M., & Mahanta, P. K. (2003). Fermentation characteristics of some assamica clones and process optimization of black tea manufacturing. Journal of Agricultural and Food Chemistry, 51, 6578–6588.

Bhattacharyya, N., Seth, S., Tudu, B., Tamuly, P., Jana, A., Gosh, D., Bandyopadhyay, R., & Bhuyan, M. (2007). Monitoring of black tea fermentation process using electronic nose. Journal of Food Engineering, 80, 1146–1156.

Borah, P., & Sit, N. (2013). Optimization of drying conditions of Xanthosoma sagittifolium (tannia) tubers in tray dryer using response surface methodology. Journal of Food Processing and Preservation. https://doi.org/10.1111/jfpp.12221.

Box, G. E. P., & Wilson, K. B. (1951). On the experimental attainment of optimum conditions. Journal of the Royal Statistical Society, B, 13, 1–45.

Chaturvedula, V. S. K., & Prakash, I. (2011). The aroma, taste, colour and bioactive constituents of tea. Journal of Medicinal Plants Research, 5, 2110–2124.

Erbay, Z., & Icier, F. (2009). A review of thin layer drying of foods: theory, modeling and experimental results. Critical Reviews in Food Science and Nutritions, 50, 441–464.

Garavand, A. T., Karimi, F., Karimi, M., Lotfi, V., & Khoobbakht, G. (2017). Hybrid response surface methodology–artificial neural network optimization of drying process of banana slices in a forced convective dryer. Food Science and Technology International, 24(4), 277–291.

John, P. (1971). Statistical design and analysis of experiments. New York: Macmillan Publishing Co..

Konar, H. S., Das, S., Datta, A. K., & Ghosh, B. C. (2012). Optimization of process parameters for vacuum drying of CTC tea. Two and a Bud, 59, 84–89.

Koneswaramoorthy, M. T., Mohamed, Z., & Galahitiyawa, G. (2004). Developing and evaluating solar energy techniques for tea drying. Journal of National Science Foundation Sri Lanka, 32, 49–60.

Lee, J., Hwang, Y. S., Kang, I. K., & Choung, M. G. (2015). Lipophilic pigments differentially respond to drying methods in tea (Camellia sinensis L.) leaves. LWT-Food Science and Technology, 61, 201–208.

Majumder, A. B., Bera, B., & Rajan, A. (2012). Tea statistics: global scenario. International Journal of Tea Science, 8, 121–124.

Manay, N. S., & Shadaksharaswamy, M. (2008). Foods facts and principles. New Delhi: New age international (P) limited.

Maran, J. P., Manikandan, S., Priya, B., & Gurumoorthi, P. (2013). Box-Behnken design based multi-response analysis and optimization of supercritical carbon dioxide extraction of bioactive flavonoid compounds from tea (Camellia sinensis L.) leaves. Journal of Food Science and Technology. https://doi.org/10.1007/s13197-013-0985-z.

Patil, V., Chauhan, A. K., & Singh, R. P. (2014). Optimization of the spray-drying process for developing guava powder using response surface methodology. Powder Technology, 253, 230–236.

Roberts, E. A. H., & Smith, R. F. (1963). Phenolic substances of manufactured tea. Spectrophotometric evaluation of tea liquors. Journal of the Science of Food and Agriculture, 14, 689–700.

Sablania, V., & Bosco, S. J. D. (2018). Optimization of spray drying parameters for Murraya koenigii (Linn) leaves extract using response surface methodology. Powder Technology, 335, 35–41.

Samanta, T., Cheeni, V., Das, S., Roy, A. B., Ghosh, B. C., & Mitra, A. (2013). Assessing biochemical changes during standardization of fermentation time and temperature for manufacturing quality black tea. Journal of Food Science and Technology, 52, 2387–2393. https://doi.org/10.1007/s13197-013-1230-5.

Scheffe, H. (1959). The analysis of variance. New York: John Wiley & Sons, Inc..

Shinde, A., Das, S., & Datta, A. K. (2013). Quality improvement of orthodox and CTC tea and performance enhancement by hybrid hot air-radio frequency (RF) dryer. Journal of Food Engineering, 116, 444–449.

Sumi, Z., Vakula, A., Tepic, A., Jelena, C. A., Vitas, J., & Pavlic, B. (2016). Modeling and optimization of red currants vacuum drying process by response surface methodology (RSM). Food Chemistry, 203, 465–475.

Temple, S. J., & Boxtel, A. J. B. V. (2000). A comparison of dryer types used for tea drying. Journal of Agricultural Engineering Research, 77, 401–407.

Teshome, K., Debela, A., & Garedew, W. (2013). Effect of drying temperature and duration on biochemical composition and quality of black tea (Camellia sinensis L.). Asian Journal of Plant Sciences, 12, 235–240.

Wani, A. A., Kaur, D., Ahmed, I., & Sogi, D. S. (2008). Extraction optimization of watermelon seed protein using response surface methodology. LWT-Food Science and Technology, 41, 1514–1520.

Yahya, M., Ruslan, M. H., Othman, M. Y., Yatim, B., Sulaiman, M. Y., Mat, S., Lim, C. H., Alghoul, M. A., Zaharim, A., & Sopian, K. (2009). Evaluation of energy requirement for drying of green tea using a solar assisted drying system (V-groove solar collector). Proceedings of the 3rd WSEAS international conference on renewable energy sources: Canary Island, 1-3 July.

Yao, L., Jiang, Y., Datta, N., Singanusong, R., Liu, X., Duan, J., Raymont, K., Lisle, A., & Xu, Y. (2004). HPLC analysis of flavanols and phenolic acids in fresh young shoots of tea (Camellia sinensis) grown in Australia. Food Chemistry, 84, 253–263.

Zhang, Y., Chen, H., Zhang, N., & Ma, L. (2013). Antioxidant and functional properties of tea protein as affected by the different tea processing methods. Journal of Food Science and Technology, 52, 742–752. https://doi.org/10.1007/s13197-013-1094-8.

Acknowledgements

The authors gratefully acknowledge Prof. Dr. B. C. Ghosh, Department of Agricultural and Food Engineering, Indian Institute of Technology, Kharagpur, for his helpful discussion and suggestions while carrying out this research work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict(s) of interest.

Rights and permissions

About this article

Cite this article

Pou, K.R.J., Tripathy, P.P. Process Optimization of Vacuum-Assisted Solar Drying of Crush, Tear and Curl (CTC) Black Tea. J. Biosyst. Eng. 45, 24–32 (2020). https://doi.org/10.1007/s42853-019-00041-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42853-019-00041-x