Abstract

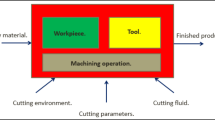

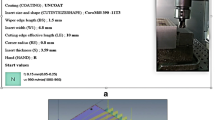

This article discuss the effects of heat treatment and lubrication modes on the machinability of A356 alloy (Al–Si–Mg), the alloy is studied as-received, with solution heat-treated alloy (SHT) as well as with solution heat-treated and then aged at 155 °C, 180 °C, and 220 °C. In the course of machinability evaluation, several criteria including cutting force, surface roughness, tool wears, and burr analysis (chip) were studied. The results and analysis in this work indicated that selected machinability criteria are important and necessary to effectively evaluate the machinability of A356 alloys. Machinability of both materials and tool was estimated in terms of cutting force, chip thickness ratio and burr formation, flank wear, and roughness. The effects of different cutting parameters (cutting speed and feed rate) and lubrication modes (dry, mist, and wet) on the machinability of A356 cast alloy were also examined. The influence of heat treatments on the burr formation and surface quality was clearly revealed by the experimental results. Experimental work revealed that cutting forces were influenced significantly by aging and cutting speed. However, the different aging at 155 °C, 180 °C, 220 °C and the cutting speed significantly affected the machinability of A356 cast alloy. The results obtained show that for better drilling performance in terms of surface quality occurs at high feed rate, dry drilling, and artificial aging at T6.

Graphical abstract

Similar content being viewed by others

References

S. Akram, H. Imran, M. Khan, et al. A numerical investigation and experimental validation on chip morphology of aluminum alloy 6061 during orthogonal machining. In: 2016 Moratuwa Engineering Research Conference (MERCon). IEEE. 331–336 (2016).

Y. Zedan, F. Samuel, A. Samuel, H. Doty, Effects of Fe intermetallics on the machinability of heat-treated Al–(7–11)% Si alloys. J. Mater. Process. Technol. 210(2), 245–257 (2010)

H. Demir, S. Gündüz, The effects of aging on machinability of 6061 aluminum alloy. Mater. Des. 30(5), 1480–1483 (2009)

D. Fratila, A. Popan, Analysis and optimization of cutting parameters in drilling operation of EM AW-2007 aluminum alloy. Acad. J. Manuf. Eng. 16, 1 (2018)

B.D. Baliga, K.N. Mohandas, T.A. Kumar, Study of machinability and corrosion behaviour of Al–Si–Mg alloy treated with master alloys. Int. J. Eng. Sci. Inn. Technol 4(3), 310–316 (2015)

V. Songmene, J. Masounave, B. Balout, Clean machining: Experimental investigation on dust formation part II: Influence of machining parameters and chip formation. Int. J. Environ. Conscious Des. Manuf. (ECDM). 14(1), 17–33 (2008)

L.K. Saunders, C.A. Mauch, An exit burr model for drilling of metals. J. Manuf. Sci. Eng. 123(4), 562–566 (2001)

L. Lauderbaugh, Analysis of the effects of process parameters on exit burrs in drilling using a combined simulation and experimental approach. J. Mater. Process. Technol. 209(4), 1909–1919 (2009)

J.C. Aurich, D. Dornfeld, P.J. Arrazola, V. Franke, L. Leitz, S. Min, Burrs-analysis, control and removal. CIRP Ann. Manuf. Technol. 58(2), 519–542 (2009)

A.S. Sofronas. The formation and control of drilling burrs. PhD Thesis, University of Detroit, USA1975.

Y. Hasegawa, Z. Shigio, Y. Akiyasu. Burrs in drilling and prevention of it. Technical paper, Society of Manufacturing Engineers, page MR. 1975:75–480.

S. Pande, H. Relekar, Investigations on reducing burr formation in drilling. Int. J. Mach. Tool Des. Res. 26(3), 339–348 (1986)

S.-L. Ko, J.-K. Lee, Analysis of burr formation in drilling with a new-concept drill. J. Mater. Process. Technol. 113(1), 392–398 (2001)

S. Shivkumar, S. Ricci, B. Steenhoff, D. Apelian, G. Sigworth, An experimental study to optimize the heat treatment of A356 alloy. AFS Trans. 97, 791–810 (1989)

A. Hetke, R. Gundlach, Aluminum casting quality in alloy 356 engine components. Am. Foundry Men’s Soc. Inc. Trans. Am. Foundry Men’s Soc. 102, 367–380 (1994)

L.R.K. Gillespie. Deburring technology for improved manufacturing. Dearborn, MI, USA: Society of Manufacturing Engineers (SME) (1981)

S.-L. Ko, Measurement and effective deburring for the micro burrs in piercing operation. Int. J. Precis. Eng. Manuf. 1(1), 152–159 (2000)

Q. Wang, C.H. Cáceres, (eds). Mg effects on the eutectic structure and tensile properties of Al–Si–Mg alloys. Materials Science Forum. Trans Tech Publ. (1996)

A. Djebara, Y. Zedan, J. Kouam et al., The effect of the heat treatment on the dust emission during machining of an Al-7Si-Mg cast alloys. J. Mater. Eng. Perform. 22(12), 3840–3853 (2013)

W.D. Callister, D.G. Rethwisch, Materials Science and Engineering: An Introduction (Wiley, New York, 2007).

J. Jorstad, Machinability of 380 alloy: Effect of minor elements and impurities. Trans. Soc. Die Cast. Eng. 79, 072 (1979)

J. Jorstad. Influence of aluminum casting alloy metallurgical factors on machinability. SAE Technical Paper (1980)

R. Burant. T. Skingle. Machining the silicon-containing aluminum alloys. SAE Technical Paper (1980)

J. Kelly, M. Cotterell, Minimal lubrication machining of aluminum alloys. J. Mater. Process. Technol. 120(1), 327–334 (2002)

D.U. Braga, A.E. Diniz, G.W. Miranda, N.L. Coppini, Using a minimum quantity of lubricant (MQL) and a diamond coated tool in the drilling of aluminum–silicon alloys. J. Mater. Process. Technol. 122(1), 127–138 (2002)

F. Klocke, G. Eisenblätter, Dry cutting. CIRP Ann. Manuf. Technol. 46(2), 519–526 (1997)

Y. Zedan, S. Niknam, A. Djebara, V. Songmene, (eds). Burr size minimization when drilling 6061-T6 aluminum alloy. ASME 2012 International Mechanical Engineering Congress and Exposition. American Society of Mechanical Engineers (2012)

R. Khettabi, M. Nouioua, A. Djebara et al., Effect of MQL and dry processes on the particle emission and part quality during milling of aluminum alloys. Int. J. Adv. Manuf. Technol. 92, 2593–2598 (2017)

S.C. Sukhpal, P. Amrit, S. Tarjeet, Performance evaluation of aluminium 6063 drilling under the influence of nanofluid minimum quantity lubrication. J. Clean. Prod. 137, 537–545 (2016)

S.A. Niknam, Y. Zedan, V. Songmene. Machining burrs formation & deburring of aluminium alloys. Light Metal Alloys Appl. p. 99–122 (2014)

P. Sreejith, B. Ngoi, Dry machining: machining of the future. J. Mater. Process. Technol. 101(1), 287–291 (2000)

S. Basavarajappa, G. Chandramohan, K.V. Narasimha Rao, R. Adhakrishanan, V. Krish. Turning of particulate metal matrix composites - review and discussion. Proceedings of the Institution of Mechanical Engineers; Jul 2006; 220, B7; Wilson Applied Science & Technology Abstracts, pp. 1189.

M.M.A.R. Hossain, Control of Distortion in Aluminium Heat Treatment. Fundamentals of Aluminium Metallurgy (Woodhead Publishing, 2018), pp. 495–524

ASM Handbook Vol. 4. Heat treating: heat treating of aluminum alloys. ASM International, Materials Information Society, U.S.A., 1990, pp. 1861–1887.

J. Kaufman, Introduction to Aluminum Alloys and Tempers (ASM international, 2000).

E. Sjölander, S. Seifeddine, The heat treatment of Al–Si–Cu–Mg casting alloys. J. Mater. Process. Technol. 210(10), 1249–1259 (2010)

F.C. Campbell (ed.), Elements of Metallurgy and Engineering Alloys (ASM International, 2008)

A.S.T.M. Standard. Standard practice for heat treatment of aluminum-alloy castings from all processes. (2004)

Y. Kaplan, et al. Comparison of the effects of B 4 C and SiC reinforcement in Al–Si matrix alloys produced via PM method. Light Metals 2019. Springer, Cham. 129–134 (2019)

S. Aksöz, B. Bostan, Effects of ageing and cryo-ageing treatments on microstructure and hardness properties of AA2014–SiC MMCs. Trans. Indian Inst. Met. 71(8), 2035–2042 (2018)

A.I. Toulfatzis et al., Machinability of eco-friendly lead-free brass alloys: cutting-force and surface-roughness optimization. Metals 8(4), 250 (2018)

E.K. Antwi, L. Kui, W. Hao, A review on ductile mode cutting of brittle materials. Front. Mech. Eng. 13(2), 251–263 (2018)

N. Yan et al., Shear localization in metallic materials at high strain rates. Progr. Mater. Sci. 2, 100755 (2020)

M. Aamir et al., A review: drilling performance and hole quality of aluminium alloys for aerospace applications. J. Mater. Res. Technol. 9(6), 12484–12500 (2020)

N. Sanaei, F. Ali, Defects in additive manufactured metals and their effect on fatigue performance: a state-of-the-art review. Progr. Mater. Sci. 2, 100724 (2020)

Acknowledgements

The authors would like to thank the Mechanics and Advanced Energy Systems Laboratory (LMSEA) and the Products, Processes and Systems Engineering Laboratory (LIPPS) for funding this research study. In addition, the authors also highly appreciated the technical support of the École de technologie supérieure de Montréal and the École nationale polytechnique de Constantine.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Alliche, M.A., Djebara, A., Zedan, Y. et al. Machinability of A356 cast alloys under the effect of artificial aging treatment and lubrication modes. JMST Adv. 3, 19–33 (2021). https://doi.org/10.1007/s42791-021-00039-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42791-021-00039-7