Abstract

Purpose

Scaffolds are artificial structures that provide a temporary template to withstand mechanical loads in vivo during the process of bone regeneration. They should present a highly porous three-dimensional structure with an interconnected network of pores for the tissue growth and the transport of nutrients and metabolic residues. Additionally, scaffolds must be easily manufactured in different shapes and sizes.

Methods

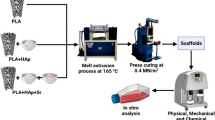

A 4 wt% of additives (alumina, zirconia, zinc oxide, hydroxyapatite, or tricalcium phosphate) was added to CAC (calcium aluminate cement), and these blends were used for scaffolds preparation via polymeric sponge replica. Aqueous suspensions were prepared with different solid contents. Sponges impregnated with 55 wt% solid were evaluated for the decomposition temperature by thermogravimetric analysis. The scaffolds microstructures were characterized by scanning electron microscopy and mercury intrusion porosimetry. The relative density was also calculated considering the theoretical density. The scaffolds (60 wt%) were characterized by cytotoxicity assay, total protein content, alkaline phosphatase activity, mineralized bone-like nodule formation, and cell adhesion.

Results

The blends prepared with 60 and 55 wt% solid were most suitable for sponge impregnation, resulting in scaffolds with higher fraction of open porosity. The tricalcium phosphate blends presented the best results regarding mineralized nodules.

Conclusion

The MTT tests and osteoblast cells adhered to the scaffolds provided predictive evidence of biocompatibility of the material which, associated with the satisfactory results obtained in the cell differentiation tests (ALP), suggested that the scaffolds developed are promising materials. Additionally, all scaffolds allowed the mineralized matrix formation which is a key issue for osteogenesis.

Similar content being viewed by others

References

Alshaaer M, Kailani MH, Ababneh N, Mallouh SA, Sweileh B, Awidi A. Fabrication of porous bioceramics for bone tissue applications using luffa cylindrical fibres (LCF) as template. Process Appl Ceram. 2017;11(1):13–20.

Bell E. Tissue engineering in perspective. J Cell Biochem. 1991;45(3):239–41.

Beloti MM, Rosa AL. Osteoblast differentiation of human bone marrow cells under continuous and discontinuos treatment with dexamethasone. Braz Dent J. 2005;16(2):156–61.

Beng QLL, Choong C. Three-dimensional scaffolds for tissue engineering apllications: role of porosity and pore size. Tissue Eng B. 2013;19(6):485–502.

Chan BP, Leong KM. Scaffolding in tissue engineering: general approaches and tissue-specific considerations. Eur Spine J. 2008;17(4):S467–79.

Cunningham E, Dunne N, Clarke S, Ying Choi S, Walker G, Wilcox R, et al. Comparative characterization of 3-D hydroxyapatite scaffolds developed via replication of synthetic polymer foams and natural marine sponges. J Tissue Sci Eng. 2011;1:2–9.

Drury JL, Mooney DJ. Hydrogels for tissue engineering: scaffold design variables and applications. Biomaterials. 2003;24(24):4337–51.

Engqvist H, Schultz-Walz JE, Loof J, Botton GA, Mayer D, Phaneuf MW, et al. Chemical and biological integration of a mouldable bioactive ceramic material capable of forming apatite in vivo in teeth. Biomaterials. 2004;25(14):2781–7.

Giesche H. Mercury porosimetry: a general (practical) overview. Part Part Syst Charact. 2006;23:1–11.

Gregory CA, Gunn WG, Peister A, Prockop DJ. An alizarin red-based assay of mineralization by adherent cells in culture: comparison with cetylpyridinium chloride extraction. Anal Biochem. 2004;329:77–84.

Haugen H, Will J, Kohler A, Hopfner U, Aigner J, Wintermantel E. Ceramic TiO2-foams: characterization of a potential scaffold. J Eur Ceram Soc. 2004;24:661–8.

Hermansson L. A review of nanostructure Ca-aluminate based biomaterials within odontology and orthopedics. J Korean Ceram Soc. 2018;55(2):95–107.

Hoemann CD, El-Gabalawy, McKee MD. In vitro osteogenesis assays: influence of the primary cell source on alkaline phosphatase activity and mineralization. Pathol Biol. 2009;57:318–23.

Hulbert SF, Young FA, Mathews RS, Klawitter JJ, Talbert CD, Stelling FH. Potential of ceramic materials as permanently implantable skeletal prostheses. J Biomed Mater Res. 1970;4(3):433–56.

Hulbert SF, Morrison SJ, Klawitter JJ. Tissue reaction to three ceramics of porous and non-porous structures. J Biomed Mater Res. 1972;6(5):347–74.

Itala AI, Ylanen HO, Ekholm C, Karlsson KH, Aro HT. Pore diameter of more than 100 micron is not requisite for bone ingrowth in rabbits. J Biomed Master Res. 2001;52(6):679–83.

Ito A, Ojima K, Naito H, Ichinose N, Tateishi T. Preparation, solubility, and cytocompatibility of zinc-releasing calcium phosphate ceramics. J Biomed Mater Res. 2000;50(2):178–83.

Jones JR, Hench LL. Regeneration of trabecular bone using porous ceramics. Curr Opinion Solid State Mater Sci. 2003;7:301–7.

Karageorgiou V, Kaplan D. Porosity of 3D biomaterial scaffolds and osteogenesis. Biomaterials. 2005;26:5474–91.

Klawitter JJ, Hulbert SF. Application of porous ceramics for the attachment of load bearing internal orthopedic applications. Biomed Mater Res. 1971;2:161–229.

Krauss FJ, Borcard F, Staedler D, Scaletta C, Applegate LA, Comas H, et al. Functionalization of microstructured open-porous bioceramic scaffolds with human fetal bone cells. Bioconjug Chem. 2012;23(11):2278–90.

Langer R, Tirrell DA. Designing materials for biology and medicine. Nature. 2004;428(6982):487–92.

Lincks J, Boyan BD, Blanchard CR, Lohmann CH, Liu Y, Cochran DL, et al. Response of MG63 osteoblast-like cells to titanium and titanium alloy is dependent on surface roughness and composition. Biomaterials. 1998;19(23):2219–32.

Loof J. Calcium-aluminate as biomaterial: synthesis, design and evaluation, Ph D thesis, Faculty of Science and Technology, Uppsala, University, Sweden; 2008, p. 87.

Loreley MA, García RC, Santos LA. Development and characterization of α-tricalcium phosphate/monocalcium aluminate composite bone cement. J Biomed Sci Eng. 2012;5:448–56.

Lowry OH, Rosenbrough NJ, Farr AL, Randall RJ. Protein measurement with the folin phenol reagent. J Biol Chem. 1951;193:265–75.

Morejón-Alonso L, Santos LA, Carrodeguas RG. Influence of mixing liquid on the properties of calcium aluminate cement. Key Eng Mater. 2009;396(398):241–4.

Mosmann T. Rapid colorimetric assay for cellular growth and survival: application to proliferation and cytotoxicity assays. J Immunol Methods. 1983;65(1–2):55–63.

Nguyen TBL, Lee BT. A combination of biphasic calcium phosphate scaffold with hyaluronic acid-gelatin hydrogel as a new tool for bone regeneration. Tissue Eng A. 2014;20(13,14):1993–2004.

Oliveira IR, Andrade TL, Pandolfelli VC, Jacobovitz M. Bioactivity of calcium aluminate endodontic cement. J Endod. 2013;39(6):774–8.

Oliveira IR, Andrade TL, Araujo KCML, Luz AP, Pandolfelli VC. Hydroxyapatite synthesis and the benefits of its blend with calcium aluminate cement. Ceram Int. 2016;42:2542–9.

Oliveira IR, Raniero LJ, Leite VCM, Castro-Raucci LMS, Oliveira PT, Pandolfelli VC. In vitro apatite-forming ability of calcium aluminate blends. Ceram Int. 2017;43:10071–9.

Parreira RM, Andrade TL, Luz AP, Pandolfelli VC, Oliveira IR. Calcium aluminate cement-based compositions for biomaterial applications. Ceram Int. 2016;42:117–38.

Rosa AL, Crippa GE, De Oliveira PT, Taba M, Lefebvre LP, Beloti MM. Human alveolar bone cell proliferation, expression of osteoblastic phenotype, and matrix mineralization on porous titanium produced by powder metallurgy. Clin Oral Implants Res. 2009;20:472–81.

Sang-Ho M, Hyeong-Ho J, Hoy-Yul P, Ik-Min P, Hong-Chae P, Seog-Young Y. Preparation of porous hydroxyapatite scaffolds for bone tissue engineering. Mater Sci Forum. 2006;510-511:754–7.

Sharmiwati MS, Mizan RM, Noorhelinahani AB. Preparation and characterization of ceramic sponge for water filter. Int J Sci Technol Res. 2014;3(6):103–6.

Sifontes AB, Urbina M, Fajardo F, Melo L, Garcia L, Mediavilla M, et al. Preparation of γ-alumina foams of high surface area employing the polyurethane sponge replica method. Lat Am Appl Res. 2010;40:185–91.

Tripkovic D, Radojevic V, Aleksic R. Factors affecting the microstructure of porous ceramic. J Serb Chem Soc. 2006;71(3):277–84.

Tsuruga E, Takita H, Itoh H, Wakisaka Y, Kuboki Y. Pore size of porous hydroxyapatite as the cell-substratum controls BMP induced osteogenesis. J Biochem. 1997;121(2):317–24.

Wójtowicz J, Leszczynska J, Chróscicka A, Slósarczyk A, Paszkiewicz Z, Zima A, et al. Press comparative in vitro study of calcium phosphate ceramics for their potency as scaffolds for tissue engineering. Biomed Mater Eng. 2014;24:1609–23.

Xiumin Y, Tan S, Zhang X, Huang Z, Jiang D. Low-temperature sintering of SiC reticulated porous ceramics with MgO–Al2O3–SiO2 additives as sintering aids. J Mater Sci. 2007;42:4960–6.

Zhongfan Z, Hongrui W, Dingzhi P. Dependence of sediment suspension viscosity on solid concentration: a simple general equation. Water. 2017;9(474):1–14.

Funding

The authors would like to acknowledge the Brazilian Research Foundations: FAPESP (2016/15032-3), CNPq (301665/2015-0), and FINEP for supporting this research, as well as Kerneos Aluminates (France) and Basf (Germany) for kindly supplying the CAC and additives samples. This study was also financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior-Brasil (CAPES)-Finance Code 001.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

All animal procedures were carried out following the guidelines of the Research Ethics Committee of the School of Dentistry of São José dos Campos (protocol 006/2016-CEUA-ICT-UNESP).

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

de Las Nieves González Vicuna, I., Grancianinov, K.J.S., dos Santos, K.W. et al. Scaffolds’ production based on calcium aluminate blends and their biological properties. Res. Biomed. Eng. 35, 131–141 (2019). https://doi.org/10.1007/s42600-019-00015-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42600-019-00015-0