Abstract

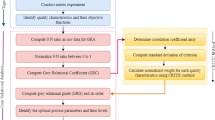

Mechanical properties of fusion welded joints can be improved by refinement of grain size. This study presents the effect of the friction stir welding process on grain refinements (grain size and grain morphology) of aluminum alloy AA2219-To butt welded joints of gas tungsten arc welding (GTAW). Traditional cold working and heat treatment processes are compared and contrasted with a novel hybrid welding approach, which incorporates the use of Friction Stir Welding (FSW) in unification with the TIG welding. Our analysis encompasses to evaluating the impact of FSW process parameters on grain refinement (grain size and morphology), particularly rotational speed (RPM), traverse speed (feed), and tool pin geometry. Employing the multi-objective Taguchi method, these FSW parameters were optimized to yield superior mechanical properties and quality features. Our results highlight that the introduction of FSW as an adjunct to traditional GTAW, a process referred to as ‘Hybrid Welding’ in this study, can achieve notable grain refinement in the Aluminum alloy welded joints.

Similar content being viewed by others

References

P. Srinivasa Rao, K.G. Sivadasan, P.K. Balasubramanian, Structure-property correlation on AA 2219 aluminium alloy weldments. Bull. Mater. Sci. 19, 549–557 (1996)

S. Malarvizhi, K. Raghukandan, N. Viswanathan, Effect of post weld aging treatment on tensile properties of electron beam welded AA2219 aluminum alloy. Int. J. Adv. Manuf. Technol. 37, 294–301 (2008)

G. Cao, S. Kou, Friction stir welding of 2219 aluminum: behavior of θ(Al2Cu) particles. Weld. J. 84, 1–8 (2005)

W. Xu, J. Liu, G. Luan, C. Dong, Microstructure and mechanical properties of friction stir welded joints in 2219–T6 aluminum alloy. Mater. Des. 30, 3460–3467 (2009)

P. Kah, R. Rajan, J. Martikainen, R. Suoranta, Investigation of weld defects in friction-stir welding and fusion welding of aluminium alloys. Int. J. Mech. Mater. Eng. 26, 1–10 (2015)

S.P. Ringer, K. Hono, Microstructural evolution and age hardening in aluminium alloys: atom probe field-ion microscopy and transmission electron microscopy studies. Mater CharactCharact 44, 101–131 (2000)

S. Pal, S.K. Malviya, S.K. Pal, A.K. Samantaray, Optimization of quality characteristics parameters in a pulsed metal inert gas welding process using grey-based Taguchi method. Int. J. Adv. Manuf. Technol. 44, 1250–1260 (2009)

Schempp, P., Grain refinement in aluminium GTA welds (2013)

W.F. Hosford, Mechanical Behavior of Materials (Cambridge University Press, Cambridge, 2010)

G.-H. Peng et al., Influence of welding processes on mechanical properties of aluminum alloy 2219. J. Aeronaut. Mater. 29, 57–60 (2009)

N. Khanna, B. Chaudhary, J. Airao, G. Dak, V.J. Badheka, Experimental comparison of TIG and friction stir welding process for AA6063-T6 aluminum alloy, in Innovations in Infrastructure. (Springer, Singapore, 2019), pp.619–628

K. Surekha, B.S. Murty, K. Prasad Rao, Microstructural characterization and corrosion behavior of multipass friction stir processed AA2219 aluminium alloy. Surf. Coat. Technol. 202, 4057–4068 (2008)

D.R. Jadhav, A study of effect process parameters on tensile strength. Int. J. Adv. Res. Eng. Technol. 10, 482–490 (2019)

J.C. Hou, H.J. Liu, Y.Q. Zhao, Influences of rotation speed on microstructures and mechanical properties of 6061–T6 aluminum alloy joints fabricated by self-reacting friction stir welding tool. Int. J. Adv. Manuf. Technol. 73, 1073–1079 (2014)

Ch. Venkata Rao, G. Madhusudhan Reddy, K. Srinivasa Rao, Influence of tool pin profile on microstructure and corrosion behaviour of AA2219 Al–Cu alloy friction stir weld nuggets. Defenc. Technol. 11, 197–208 (2015)

D. Venkateswarlu, M. Cheepu, B. Kranthi Kumar, M.M. Mahapatra, Analysing the friction stir welded joints of AA2219 Al-Cu alloy in different heat-treated-state. IOP Conf. Ser. Mater. Sci. Eng. 330, 012074 (2018)

H.J. Liu, J.Q. Li, W.J. Duan, Friction stir welding characteristics of 2219–T6 aluminum alloy assisted by external non-rotational shoulder. Int. J. Adv. Manuf. Technol. 64, 1685–1694 (2013)

A.B. Ibrahim, F.A. Al-Badour, A.Y. Adesina, N. Merah, Effect of process parameters on microstructural and mechanical properties of friction stir diffusion cladded ASTM A516–70 steel using 5052 Al alloy. J. Manuf. Process. 34, 451–462 (2018)

Y. Chen, H. Liu, J. Feng, Friction stir welding characteristics of different heat-treated-state 2219 aluminum alloy plates. Mater. Sci. Eng. A 420, 21–25 (2006)

R.S. Mishra, H. Mehdi, Study of the influence of friction stir processing on tungsten inert gas welding of different aluminum alloy. SN Appl. Sci. 1, 712 (2019)

M.M. El-Sayed, A.Y. Shash, T.S. Mahmoud, M.A. Rabbou, Effect of friction stir welding parameters on the peak temperature and the mechanical properties of aluminum alloy 5083-O, in Improved Performance of Materials. (Springer, Cham, 2018), pp.11–25

M.A. Mohamed, Y.H.P. Manurung, M.N. Berhan, Model development for mechanical properties and weld quality class of friction stir welding using multi-objective Taguchi method and response surface methodology. J. Mech. Sci. Technol. 29, 2323–2331 (2015)

D. Trimble, J. Monaghan, G.E. O’Donnell, Force generation during friction stir welding of AA2024-T3. CIRP Ann. 61, 9–12 (2012)

T.H. North, G.J. Bendzsak, Y. Zhai, Z. Li, Particle fracture, retention, and fluid flow in metal matrix composite friction joints. Metallur. Mater. Trans. A 28, 2371–2384 (1997)

P. Podržaj, B. Jerman, D. Klobčar, Welding defects at friction stir welding. Metalurgija 54(2), 387–389 (2015)

Y. Zhai, C. Maldonado, T.H. North, G.B. Bendzsak, Particle agglomeration and fracture in MA 956 and MMC friction joints. Int. J. Mater. Prod. Technol. 13, 89–104 (1998)

S. Malarvizhi, V. Balasubramanian, Effect of welding processes on AA2219 aluminium alloy joint properties. Trans. Nonferrous Met. Soc. China 21, 962–973 (2011)

J.A. Hartman, R.J. Beil, G.T. Hahn, Effect of copper rich regions on tensile properties of VPPA weldments of 2219–T87 aluminum. Weld. J. 1, 73–83 (1987)

S.E. Stanzn-Tschegg, O. Plasser, E.K. Tschegg, A.K. Vasudevan, Influence of microstructure and load ratio onfatigue threshold behaviour in 7075 alloys. Int. J. Fatigue 21(1), 255–262 (1999)

S. Kou, Welding Metallurgy, 2nd edn. (Wiley, New York, 2003), pp.304–314

K. Nakata, Y.G. Kim, M. Ushio, T. Hashimoto, S. Jyogan, Weldability of high strength aluminum alloys by friction stir welding. ISIJ Int. 40, S15–S21 (2000)

The Aluminum Association, Aluminum Standards and Data (The Aluminum Association, Washington, DC, 1982), p.15

T. Bagchi, Taguchi’s Methods Explained: Practical Steps to Robust Design (Prentice Hall of India, Delhi, 1992)

J. Ross Phillip, Taguchi Techniques for Quality Engineering (McGraw Hill, New York, 1988)

A. Khan, Q. Saghir, A. Raza, Determining the effects of selected cutting parameters on circularity and cylindricity in turning operations for steel 4140 using Taguchi methods. Electron. Res. J. Eng. Comput. Appl. Sci. 1, 14–29 (2019). https://doi.org/10.13140/RG.2.2.18328.21768

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no known competing and financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ahmad, S., Khan, A., Mehmood, A. et al. Taguchi-Optimized Friction Stir Welding of Aluminum Alloy AA2219: Investigating the Influence of Process Parameters on Mechanical Properties Via Grain Refinement. Multiscale Sci. Eng. 5, 166–179 (2023). https://doi.org/10.1007/s42493-024-00104-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42493-024-00104-y