Abstract

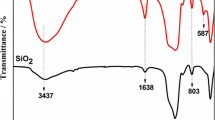

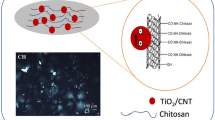

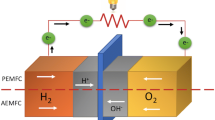

Chitosan is considered one of the most promising materials for polymer electrolyte membrane fuel cells (PEMFC) due to the high manufacturing cost of the commercial polymer electrolyte membrane (PEM). In this study, chitosan (C-1), chloroacetate chitosan (CCS-21), epoxidized natural rubber (ENR-41), chitosan blended with ENR (CE-6 and CE-7), and chloroacetate chitosan blended with ENR (CCE-26 and CCE-27) based membranes were prepared by solution casting technique and crosslinked with acid and base. The Fourier transform infrared (FTIR) spectroscopy results showed improvements in their peaks, and the atomic force microscopy revealed that the blended membranes had a higher surface roughness than the other membranes. The optical contact angle (OCA) showed that the C-1 had the highest contact angle, while the ENR-41 had the least contact angle. From the electrical measurements, the CCS-21 gave the highest capacitance, conductance, and conductivity. The CE-7 showed the highest resistance and resistivity while ENR-41 showed the highest dissipation factor and dielectric constant. Taken together, CE-7 showed the most suitable characteristics which makes it suitable for use as a PEM.

Similar content being viewed by others

Data availability

The datasets generated and analyzed during the current study are available from the corresponding author on reasonable request.

References

Wakihara M (2001) Recent developments in lithium ion batteries. Mater Sci Eng R 33(4):109–134. https://doi.org/10.1016/S0927-796X(01)00030-4

Appleby AJ, Foulkes FR (1989) Fuel cell handbook. Van Nostrand Reinhold, New York

Smitha B, Sridhar S, Khan AA (2006) Chitosan–poly(vinyl pyrrolidone) blends as membranes for direct methanol fuel cell applications. J Power Sources 159(2):846–854. https://doi.org/10.1016/j.jpowsour.2005.12.032

Heinzel A, Barragán VM (1999) A review of the state-of-the-art of the methanol crossover in direct methanol fuel cells. J Power Sources 84(1):70–74. https://doi.org/10.1016/S0378-7753(99)00302-X

Kamarudin SK, Achmad F, Daud WRW (2009) Overview on the application of direct methanol fuel cell (DMFC) for portable electronic devices. Int J Hydrogen Energy 34(16):6902–6916. https://doi.org/10.1016/j.ijhydene.2009.06.013

Beattie PD, Orfino FP, Basura VI, Zychowska K, Ding J, Chuy C, Schmeisser J, Holdcroft S (2001) Ionic conductivity of proton exchange membranes. J Electroanal Chem 503(1–2):45–56. https://doi.org/10.1016/S0022-0728(01)00355-2

Hasani-Sadrabadi MM, Dorri NM, Ghaffarian SR, Dashtimoghadam E, Sarikhani K, Majedi FS (2010) Effects of organically modified nanoclay on the transport properties and electrochemical performance of acid-doped polybenzimidazole membranes. J Appl Polym Sci 117(2):1227–1233. https://doi.org/10.1002/app.31974

Blair HS, Ho T-C (2007) Studies in the adsorption and diffusion of ions in chitosan. J Chem Technol Biotechnol 31(1):6–10. https://doi.org/10.1002/jctb.503310103

Cui Z, Xiang Y, Si J, Yang M, Zhang Q, Zhang T (2008) Ionic interactions between sulfuric acid and chitosan membranes. Carbohyd Polym 73(1):111–116. https://doi.org/10.1016/j.carbpol.2007.11.009

Krajewska B, Olech A (1996) Pore structure of gel chitosan membranes. I. Solute diffusion measurements. Polym Gels Netw 4(1):33–43. https://doi.org/10.1016/0966-7822(95)00015-1

Wan Y, Creber KAM, Peppley B, Bui VT (2003) Ionic conductivity of chitosan membranes. Polymer 44(4):1057–1065. https://doi.org/10.1016/S0032-3861(02)00881-9

Niamsa N, Baimark Y (2009) Preparation and characterization of highly flexible chitosan films for use as food packaging. Am J Food Technol 4(4):162–169. https://doi.org/10.3923/ajft.2009.162.169

Krajewska B (2001) Diffusional properties of chitosan hydrogel membranes. J Chem Technol Biotechnol 76(6):636–642. https://doi.org/10.1002/jctb.429

Matsuyama H, Kitamura Y, Naramura Y (1999) Diffusive permeability of ionic solutes in charged chitosan membrane. J Appl Polym Sci 72(3):397–404. https://doi.org/10.1002/(SICI)1097-4628(19990418)72:3%3c397::AID-APP9%3e3.0.CO;2-C

Wang XP, Shen ZQ, Zhang FY, Zhang YF (1996) A novel composite chitosan membrane for the separation of alcohol-water mixtures. J Membr Sci 119(2):191–198. https://doi.org/10.1016/0376-7388(96)00157-3

Wei YC, Hudson SM, Mayer JM, Kaplan DL (1992) The crosslinking of chitosan fibers. J Polym Sci Part A 30(10):2187–2193. https://doi.org/10.1002/pola.1992.080301013

Wan Y, Creber KAM, Peppley B, Bui VT (2003) Ionic conductivity and related properties of crosslinked chitosan membranes. J Appl Polym Sci 89(2):306–317. https://doi.org/10.1002/app.12090

Wan Y, Peppley B, Creber KAM, Bui VT (2010) Anion-exchange membranes composed of quaternized-chitosan derivatives for alkaline fuel cells. J Power Sources 195(12):3785–3793. https://doi.org/10.1016/j.jpowsour.2009.11.123

Ali Q, Taweepreda W, Techato K (2020) Preparation and characterization of polymer electrolyte membrane from chloroacetate chitosan/chitosan blended with epoxidized natural rubber. Polym Testing 82:106294. https://doi.org/10.1016/j.polymertesting.2019.106294

Baker CSL, Gelling IR, Newell R (1985) Epoxidized natural rubber. Rubber Chem Technol 58(1):67–85. https://doi.org/10.5254/1.3536059

Ismail H, Shaari SM, Othman N (2011) The effect of chitosan loading on the curing characteristics, mechanical and morphological properties of chitosan-filled natural rubber (NR), epoxidised natural rubber (ENR) and styrene-butadiene rubber (SBR) compounds. Polym Testing 30(7):784–790. https://doi.org/10.1016/j.polymertesting.2011.07.003

Yoksan R (2008) Epoxidized natural rubber for adhesive applications. Nat Sci 42(5):325–332. https://doi.org/10.1007/978-3-642-14094-5

Idris R, Glasse MD, Latham RJ, Linford RG, Schlindwein WS (2001) Polymer electrolytes based on modified natural rubber for use in rechargeable lithium batteries. J Power Sources 94(2):206–211. https://doi.org/10.1016/S0378-7753(00)00588-7

Raju G, Mas Haris MRH (2016) Preparation and characterization of acidified chitosan immobilized in epoxidized natural rubber. Polym Testing 53:1–6. https://doi.org/10.1016/j.polymertesting.2016.05.005

Ahmed F, Kumar S, Arshi N, Anwar MS, Su-Yeon L, Kil GS, Park DW, Koo BH, Lee CG (2011) Preparation and characterizations of polyaniline (PANI)/ZnO nanocomposites film using solution casting method. Thin Solid Films 519(23):8375–8378. https://doi.org/10.1016/j.tsf.2011.03.090

Mariani E, Eckstein J, Rubínová E (1967) Permittivity, dielectric loss and dc conductivity of NaNO3 crystals grown by epitaxy. Czech J Phys 17(6):552–558. https://doi.org/10.1007/BF01695178

Edmondson CA, Stallworth PE, Wintersgill MC, Fontanella JJ, Dai Y, Greenbaum SG (1998) Electrical conductivity and NMR studies of methanol/water mixtures in Na ® on membranes. Electrochimica Acta 43(10–11):1295–1299. https://doi.org/10.1016/S0013-4686(97)10033-0

Taweepreda W, Wichianchom A (2013) Fabrication and characterization of epoxidized natural rubber-chitosan membrane. Adv Mater Res 844:205–208. https://doi.org/10.4028/www.scientific.net/amr.844.205

Wanichapichart P, Sungkum R, Taweepreda W, Nisoa M (2009) Characteristics of chitosan membranes modified by argon plasmas. Surf Coat Technol 203(17–18):2531–2535. https://doi.org/10.1016/j.surfcoat.2009.02.069

Smitha B, Sridhar S, Khan AA (2005) Chitosan-sodium alginate polyion complexes as fuel cell membranes. Eur Polymer J 41(8):1859–1866. https://doi.org/10.1016/j.eurpolymj.2005.02.018

Balau L, Lisa G, Popa MI, Tura V, Melnig V (2004) Physico-chemical properties of chitosan films. Cent Eur J Chem 2(4):638–647. https://doi.org/10.2478/BF02482727

Cho SA, Cho EA, Oh IH, Kim HJ, Ha HY, Hong SA, Ju JB (2006) Surface modified Nafion® membrane by ion beam bombardment for fuel cell applications. J Power Sources 155(2):286–290. https://doi.org/10.1097/01.mcg.0000210103.82241.97

De Oliveira RRL, Albuquerque DAC, Cruz TGS, Yamaji FM, Leite FL (2012) Measurement of the nanoscale roughness by atomic force microscopy: basic principles and applications [Internet]. In: Atomic force microscopy—imaging, measuring and manipulating surfaces at the atomic scale. InTech, London. https://doi.org/10.5772/37583

Lehmani A, Durand-Vidal S, Turq P (1998) Surface morphology of nafion 117 membrane by tapping mode atomic force microscope. J Appl Polym Sci 68(3):503–508. https://doi.org/10.1002/(SICI)1097-4628(19980418)68:3%3c503::AID-APP16%3e3.0.CO;2-V

Liu J, Wang H, Cheng S, Chan KY (2005) Nafion-polyfurfuryl alcohol nanocomposite membranes for direct methanol fuel cells. J Membr Sci 246(1):95–101. https://doi.org/10.1016/j.memsci.2004.08.016

Rankl M, Laib S, Seeger S (2003) Surface tension properties of surface-coatings for application in biodiagnostics determined by contact angle measurements. Coll Surf B 30(3):177–186. https://doi.org/10.1016/S0927-7765(03)00085-7

Zawodzinski TA, Gottesfeld S, Shoichet S, McCarthy TJ (1993) The contact angle between water and the surface of perfluorosulphonic acid membranes. J Appl Electrochem 23(1):86–88. https://doi.org/10.1007/BF00241582

Bass M, Berman A, Singh A, Konovalov O, Freger V (2010) Surface structure of nafion in vapor and liquid. J Phys Chem B 114(11):3784–3790. https://doi.org/10.1021/jp9113128

Goswami S, Klaus S, Benziger J (2008) Wetting and absorption of water drops on nafion films. Langmuir 51:8627–8633. https://doi.org/10.1021/la800799a

Moilanen DE, Piletic IR, Fayer MD (2007) Water dynamics in nafion fuel cell membranes: the effects of confinement and structural changes on the hydrogen bond network. J Phys Chem C 111(25):8884–8891. https://doi.org/10.1021/jp067460k

Baustista-Rodríguez CM, Rosas-Paleta A, Rivera-Márquez JA, Solorza-Feria O (2009) Study of electrical resistance on the surface of nafion 115® membrane used as electrolyte in PEMFC technology part I: Statistical inference. Int J Electrochem Sci 4(1):43–59

Fontanella JJ, Edmondson CA, Wintersgill MC, Wu Y, Greenbaum SG (1996) High-pressure electrical conductivity and NMR studies in variable equivalent weight Nafion membranes. Macromolecules 29(14):4944–4951. https://doi.org/10.1021/ma9600926

Zaidi SMJ (2005) Preparation and characterization of composite membranes using blends of SPEEK/PBI with boron phosphate. Electrochim Acta 50(24):4771–4777. https://doi.org/10.1016/j.electacta.2005.02.027

Opekar F, Svozil D (1995) Electric resistance in a Nafion® membrane exposed to air after a step change in the relative humidity. J Electroanal Chem 385(2):269–271. https://doi.org/10.1016/0022-0728(95)03767-B

Dweiri R, Sahari J (2007) Electrical properties of carbon-based polypropylene composites for bipolar plates in polymer electrolyte membrane fuel cell (PEMFC). J Power Sources 171(2):424–432. https://doi.org/10.1016/j.jpowsour.2007.05.106

Yusmaniar Y, Afrizal A, Nurzaman N, Handoko E (2018) Structure and electrical properties of polymer electrolyte membrane for fuel cell application. MATEC Web Conf 197(12 September 2018):04003. https://doi.org/10.1051/matecconf/201819704003

Lu Z, Lanagan M, Manias E, Macdonald D (2010) Dielectric properties of polymer electrolyte membranes measured by two-port transmission line technique. Electrochem Soc 28(29):95–105. https://doi.org/10.1149/1.3502448

Gimba ID, Abdulkareem AS, Jimoh A, Afolabi AS (2016) Theoretical energy and exergy analyses of proton exchange membrane fuel cell by computer simulation. J Appl Chem. https://doi.org/10.1155/2016/2684919

Lu Z, Polizos G, Macdonald DD, Manias E (2008) State of water in perfluorosulfonic ionomer (Nafion 117) proton exchange membranes. J Electrochem Soc 155(2):B163. https://doi.org/10.1149/1.2815444

Taweepreda W (2014) Dynamic mechanical and dielectric properties of modified surface chitosan/natural rubber latex. Sains Malaysiana 43(2):241–245

Acknowledgements

AW would like to thank the Thai Government Scholarship for Ph.D. studentship and grateful to thank Rajamangala University of Technology Srivijaya, Nakhon Si Thammarat Saiyai Campus and Faculty of Science, Prince of Songkla University for others supporting.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wichianchom, A., Taweepreda, W., Ali, Q. et al. Modification of chitosan-based membrane with epoxidized natural rubber for PEMFC application. J Rubber Res 26, 233–247 (2023). https://doi.org/10.1007/s42464-023-00215-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42464-023-00215-5