Abstract

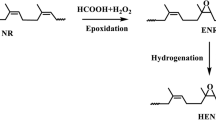

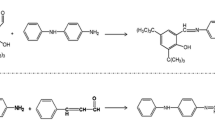

Natural rubber (NR) contains cis-1,4-polyisoprene and many kinds of non-rubber components, e.g., proteins, lipids and phospholipids, which are believed to affect the properties of NR. Oxidative degradation is one of the problems for rubber performance, which shorten the service life of the product. To overcome this problem, the influence of fatty acids and proteins on the cure properties, heat-ageing behaviours, and ozone resistance of NR vulcanizates were investigated. The peroxide vulcanization was chosen to avoid the effect of essential fatty acid and proteins. The purified NR, deproteinized NR (DPNR) and lipids-removed NR (LRNR) were mixed with model fatty acid (stearic acid) and amino acid (alanine). It was found that the cure behaviour of these mixed samples showed almost the same trend. After removing proteins, the rate of oxidative degradation was faster than that of the lipid-removal samples. Lower lipid content would result in less oxidative degradation of the rubber. These findings can infer that the endogenous proteins in NR act as natural antioxidants, while the endogenous lipids are pro-oxidants.

Similar content being viewed by others

References

Vaysse L, Bonfils F, Sainte-Beuve J, Cartault M (2012) Natural rubber. In: Matyjaszewski K, Möller M (eds) Polymer science: a comprehensive reference. Elsevier, Amsterdam, pp 281–293. https://doi.org/10.1016/B978-0-444-53349-4.00267-3

Murniati R, Sutisna WE, Rokhmat M, Iskandar F, Abdullah M (2017) Natural rubber nanocomposite as human-tissue-mimicking materials for replacement cadaver in medical surgical practice. ProcEng 170:101–107. https://doi.org/10.1016/j.proeng.2017.03.019

Furuya M, Shimono N, Okamoto M (2017) Fabrication of biocomposites composed of natural rubber latex and bone tissue derived from MC3T3-E1 mouse preosteoblastic cells. Nanocomposites 3(2):76–83. https://doi.org/10.1080/20550324.2017.1352111

Mohammadi H, Morovati V, Poshtan E, Dargazany R (2020) Understanding decay functions and their contribution in modelling of thermal-induced aging of crosslinked polymers. PolymDegrad Stab 175:109108. https://doi.org/10.1016/j.polymdegradstab.2020.109108

Celina MC (2013) Review of polymer oxidation and its relationship with materials performance and lifetime prediction. PolymDegrad Stab 98(12):2419–2429. https://doi.org/10.1016/j.polymdegradstab.2013.06.024

Li G-Y, Koenig J (2005) A review of rubber oxidation. Rubber ChemTechnol 78:355–390. https://doi.org/10.5254/1.3547888

Zhang B-L, Chen M, Ao N-J, Deng W-Y, Liu H-L (2004) Study on hot air aging and thermooxidative degradation of peroxide prevulcanized natural rubber latex film. J ApplPolymSci 92(5):3196–3200. https://doi.org/10.1002/app.20313

Čulin J, Gembarovski D, Andreis M, Veksli Z, Marinović T (2000) Effect of thermal oxidative ageing on the morphology of natural rubber networks as viewed by ESR. PolymInt 49(8):845–852. https://doi.org/10.1002/1097-0126(200008)49:8%3c845::AID-PI465%3e3.0.CO;2-O

Mei C, Yong-Zhou W, Guang L, Xiao-Ping W (2012) Effects of different drying methods on the microstructure and thermal oxidative aging resistance of natural rubber. J ApplPolymSci 126(6):1808–1813. https://doi.org/10.1002/app.34300

Samsuri AB, Abdullahi AA (2017) Degradation of natural rubber and synthetic elastomers. Reference module in materials science and materials engineering. Elsevier. https://doi.org/10.1016/B978-0-12-803581-8.09212-2

Fo G, Chazeau L, Chenal J-M, Schach R (2019) About thermo-oxidative ageing at moderate temperature of conventionally vulcanized natural rubber. PolymDegrad Stab 161:74–84. https://doi.org/10.1016/j.polymdegradstab.2018.12.029

Chandrasekaran VC (2010) Service life of rubber-lined chemical equipment. Rubber as a construction material for corrosion protection. Wiley, pp 235–248. https://doi.org/10.1002/9780470893197.ch15

Lee YH, Cho M, Nam J-D, Lee Y (2018) Effect of ZnO particle sizes on thermal aging behaviour of natural rubber vulcanizates. PolymDegrad Stab 148:50–55. https://doi.org/10.1016/j.polymdegradstab.2018.01.004

Bonfils F, Laigneau JC, Sylla S, Beuve JS (2001) DSC valuation of PRI of raw natural rubber. J ApplPolymSci 79(13):2354–2359. https://doi.org/10.1002/1097-4628(20010328)79:13%3c2354::AID-APP1044%3e3.0.CO;2-S

Nie S, Lacayo-Pineda J, Willenbacher N, Wilhelm M (2019) Aging of natural rubber studied via Fourier-transform rheology and double quantum NMR to correlate local chain dynamics with macroscopic mechanical response. Polymer 181:121804. https://doi.org/10.1016/j.polymer.2019.121804

Nun-anan P, Wisunthorn S, Pichaiyut S, Nathaworn CD, Nakason C (2020) Influence of non-rubber components on properties of unvulcanized natural rubber. PolymAdvTechnol 31(1):44–59. https://doi.org/10.1002/pat.4746

Sriring M, Nimpaiboon A, Kumarn S, Takahara A, Sakdapipanich J (2020) Enhancing viscoelastic and mechanical performances of natural rubber through variation of large and small rubber particle combinations. Polym Test 81:106225. https://doi.org/10.1016/j.polymertesting.2019.106225

Amnuaypornsri S, Sakdapipanich J, Toki S, Hsiao BS, Ichikawa N, Tanaka Y (2008) Strain-induced crystallization of natural rubber: effect of proteins and phospholipids. Rubber ChemTechnol 81(5):753–766. https://doi.org/10.5254/1.3548230

Zhou Y, Kosugi K, Yamamoto Y, Kawahara S (2017) Effect of non-rubber components on the mechanical properties of natural rubber. PolymAdvTechnol 28(2):159–165. https://doi.org/10.1002/pat.3870

Tuampoemsab S, Sakdapipanich J, Tanaka Y (2007) Influence of some non-rubber components on aging behavior of purified natural rubber. RubberChemTechnol 80(1):159–168. https://doi.org/10.5254/1.3548163

Tuampoemsab S, Sakdapipanich J (2007) Role of naturally occurring lipids and proteins on thermal aging behaviour of purified natural rubber. KautschGummiKunstst 60(12):678–684

Tuampoemsab S (2013) Influence of amino acids on anti-oxidative properties of green natural rubber and natural rubber compound. Adv Mater Res 747:664–667

Lhamo D, McMahan C (2017) Effect of protein addition on properties of guayule natural rubber. RubberChemTechnol 90(2):387–404. https://doi.org/10.5254/rct.17.83746

Kongkaew C, Intiya W, Loykulnant S, Sae-oui P (2017) Effect of protein crosslinking by Maillard reaction on natural rubber properties. KautschGummiKunstst 70:37–41

Wei Y-C, Liu G-X, Zhang H-F, Zhao F, Luo M-C, Liao S (2019) Non-rubber components tuning mechanical properties of natural rubber from vulcanization kinetics. Polymer 183:121911. https://doi.org/10.1016/j.polymer.2019.121911

Junkong P, Morimoto R, Miyaji K, Tohsan A, Sakaki Y, Ikeda Y (2020) Effect of fatty acids on the accelerated sulfur vulcanization of rubber by active zinc/carboxylate complexes. RSC Adv 10(8):4772–4785. https://doi.org/10.1039/C9RA10358A

Wei Y-C, Liu G-X, Zhang L, Xu W-Z, Liao S, Luo M-C (2020) Mimicking the mechanical robustness of natural rubber based on a sacrificial network constructed by phospholipids. ACS Appl Mater Interfaces 12(12):14468–14475. https://doi.org/10.1021/acsami.0c01994

Kruželák JN, Sýkora R, Hudec I (2014) Peroxide vulcanization of natural rubber. Part I: effect of temperature and peroxide concentration. J PolymEng. https://doi.org/10.1515/polyeng-2014-0034

Dluzneski PR (2001) Peroxide vulcanization of elastomers. Rubber ChemTechnol 74(3):451–492. https://doi.org/10.5254/1.3547647

Hasma H (1991) Lipids associated with rubber particles and their possible role in mechanical stability of latex concentrates. J Rubber Res 6(2):105–114

Liengprayoon S, Chaiyut J, Sriroth K, Fdr B, Jrm S-B, Dubreucq E, Vaysse L (2013) Lipid compositions of latex and sheet rubber from Hevea brasiliensis depend on clonal origin. Eur J Lipid SciTechnol 115(9):1021–1031. https://doi.org/10.1002/ejlt.201300023

Brzozowska J, Hanower P, Chezeau R (1974) Free amino acids of Hevea brasiliensis latex. Experientia 30(8):894–896. https://doi.org/10.1007/BF01938345

Yunyongwattanakorn J, Tanaka Y, Sakdapipanich J, Wongsasutthikul V (2008) Highly-purified natural rubber by saponification of latex: analysis of residual proteins in saponified natural rubber. RubberChemTechnol 81(1):121–137. https://doi.org/10.5254/1.3548192

Nawamawat K, Sakdapipanich JT, Ho CC (2010) Effect of deproteinized methods on the proteins and properties of natural rubber latex during storage. MacromolSymp 288(1):95–103. https://doi.org/10.1002/masy.201050212

Folch J, Lees M, Stanley GHS (1957) A simple method for the isolation and purification of total lipids from animal tissues. J BiolChem 226(1):497–509

Sakdapipanich J, Insom K, Phupewkeaw N (2007) Composition of color substances of Hevea brasiliensis natural rubber. RubberChemTechnol 80(2):212–230. https://doi.org/10.5254/1.3539403

Sriring M, Nimpaiboon A, Kumarn S, Sirisinha C, Sakdapipanich J, Toki S (2018) Viscoelastic and mechanical properties of large- and small-particle natural rubber before and after vulcanization. Polym Test 70:127–134. https://doi.org/10.1016/j.polymertesting.2018.06.026

John FP (1953) Principles of polymer chemistry, 1st edn. Cornell University Press, New York, p 29

Flory PJ (1950) Statistical mechanics of swelling of network structures. J ChemPhys 18:108–111. https://doi.org/10.1063/1.1747424

Smitthipong W, Tantatherdtam R, Rungsanthien K, Suwanruji P, Sriroth K, Radabutra S, Thanawan S, Vallat M-F, Nardin M, Mougin K, Chollakup R (2013) Effect of non-rubber components on properties of sulphur crosslinked natural rubbers. Adv Mater Res 844:345–348

Arnold AR, Evans P (1991) Role of fatty acids in autoxidation of deproteinized natural rubber. J Nat Rubber Res 6:75

Tuampoemsab S, Rattanapan A, Pakeyangkoon P (2014) Antagonism of natural anti- and pro-oxidants in synthetic polyisoprene rubber vulcanizates. Adv Mater Res 979:159–162

Acknowledgements

The authors gratefully acknowledge Royal Golden Jubilee for PhD. Program, and the Center of Excellence for Innovation in Chemistry (PERCH-CIC), Ministry of Higher Education, Science, Research and Innovation. Sincere appreciation is extended to the Thai Rubber Latex Group Public Co., Ltd. for supporting NR latex.

Funding

This work was supported by the Royal Golden Jubilee PhD. Program [grant numbers PhD/0150/2560], Ministry of Higher Education, Science, Research and Innovation.

Author information

Authors and Affiliations

Contributions

The manuscript was written through the contributions of all authors. All authors have approved the final version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships which have or could be perceived to have influenced the work reported in this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Payungwong, N., Tuampoemsab, S., Rojruthai, P. et al. The role of model fatty acid and protein on thermal aging and ozone resistance of peroxide vulcanized natural rubber. J Rubber Res 24, 543–553 (2021). https://doi.org/10.1007/s42464-021-00100-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42464-021-00100-z