Abstract

The characterization of respirable dust on the basis of constituent fractions and particle sizes is increasingly of concern for evaluating exposure hazards. For high-resolution particle analysis, scanning electron microscopy with energy dispersive X-ray (SEM-EDX) can be an effective tool. However, it requires particles to be deposited on a smooth, uniform substrate such as a polycarbonate (PC) filter for optimal results. While direct sampling onto PC is possible, this is not the standard approach in many situations. For example, in coal mines, respirable dust samples have typically been collected onto polyvinyl chloride (PVC) filters because they are intended for gravimetric and/or infrared spectroscopy analysis. Such fibrous substrates are not ideal for SEM-EDX (or other microscopy), but an effective method to recover and redeposit the dust particles could render such samples suitable for the additional analysis. Here, we present a simple method and compare SEM-EDX results for paired samples analyzed directly on PC and following recovery from PVC and redeposition on PC. Both laboratory-generated dust samples (n = 10 pairs) and field samples of respirable coal mine dust (n = 44 pairs) are included in this study. Although some changes in particle size distributions were observed between samples analyzed directly and those that were recovered and redeposited prior to analysis, the results indicate the dust recovery method generally yields a representative sample in terms of mineral constituents. That said, results also highlighted the effects of high particle loading density on individual particle analysis. Considering all sample pairs, those with similar loading density between the directly analyzed and recovered sample tended to exhibit similar mineralogy distributions. This was generally the case for the lab-generated sample pairs, and the Freeman-Halton exact test of independence indicated that the samples in just three (of 10) pairs were in disagreement in terms of their mineralogy distributions. On the other hand, for the field samples, the directly analyzed sample often had higher loading density than the recovered sample; and the Freeman-Halton test showed that 25 (of 44) pairs were in disagreement. However, the effect of possible particle agglomeration on the directly analyzed samples cannot be ruled out—and exploration of this factor was beyond the scope of the current study.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Traditionally, both ambient and occupational exposures to inhalable and respirable particulates have been assessed on the basis of mass concentration (e.g., see [1]). However, there is increasingly a focus on the evaluation of particle characteristics to better understand exposure hazards [2,3,4]. For instance, particle size can control lung deposition [5,6,7]; and particle surface area and chemistry can control lung response [8,9,10,11]. In light of the unexpected resurgence of occupational lung disease among US coal miners [12], a consensus report from the National Academies of Science, Engineering, and Medicine recently called for more in-depth characterization of respirable coal mine dust (RCMD) to enable a clearer understanding of both dust sources and health implications [13].

Although various instruments are available for generic particle counting and sizing, to conduct chemical or mineralogical analysis at the individual particle level, microscopy has been used [14]. For particles in the respirable range (i.e., on the order of microns and finer), scanning electron microscopy with energy dispersive X-ray (SEM-EDX) can be used to simultaneously acquire particle size and shape data (i.e., from the SEM images) along with chemistry (i.e., from the EDX spectra); and the chemistry can be interpreted to infer mineralogy. Then, particle data can be summed to estimate distributions for an entire sample. Due to the time-consuming nature of manually analyzing individual particles by SEM-EDX, computer algorithms can be used to automate the process and more easily generate quantitative data on a per sample basis (i.e., which requires analysis of relatively many particles in a sample). In fact, computer-controlled SEM-EDX routines specific to RCMD analysis have previously been developed and used by the authors [15,16,17,18,19].

One important condition for automated SEM-EDX analysis is that the particles are deposited on a suitable substrate—meaning one that allows for an image processing routine to accurately identify particles in contrast to the background, and also exhibits uniform composition so as not to interfere with EDX analysis on the particles. Track-etched polycarbonate (PC) filters are commonly used for this work because their smooth surface, low impurity, and consistently sized pores are ideal for both sample collection and analysis [20,21,22]. If a dust sample is collected on PC or other suitable filter media, SEM-EDX analysis can potentially be conducted directly on the sample filter. However, in many cases, samples are primarily collected for other types of analyses [23, 24]. For example, polyvinyl chloride (PVC) filters are commonly used to sample respirable dust when the primary aim is gravimetric analysis to determine the mass concentration in the environment [25, 26]; the fibrous structure of PVC helps trap particles to avoid sample mass loss during handling, and it is non-hygroscopic which minimizes effects of humidity on weight measurements. For respirable mine dust, including RCMD, sampling on PVC filters also enables the determination of quartz using infrared spectroscopy methods such as NIOSH method 7603 [27] and MSHA method P7 [28], both of which require recovery of the dust sample from the PVC filter medium and redeposition onto another filter medium to allow for analysis. Recently, NIOSH has developed a direct-on-filter Fourier transform infrared (FT-IR) method for analysis which does not require dust recovery or redeposition [29,30,31,32]. To use such PVC filter samples for microscopy analysis though, the dust particles should ideally be recovered and redeposited on a suitable substrate like PC [33]. This is because, even if the PVC composition itself does not interfere with EDX analysis of the particles, the fibrous nature of the material can hinder particle identification (versus background), especially for automated work; and indeed, particles embedded in the filter (rather than sitting on the surface) may not be seen at all.

Recovery of particles from air sampling filters has been performed for a number of different applications including chemical and toxicological analysis of ambient particulate matter [34, 35]; and forensic analysis of dust and microbial particles collected in heating, ventilation, and air conditioning systems [36, 37]. Depending on the filter media properties and the intended analysis, some particle recovery methods involve filter destruction (e.g., by ashing or digestion) such that the sample residue is the target of analysis [28, 38, 39], and others involve keeping the filter intact and simply dislodging and capturing the particles for analysis [40]. Considering the specific aim to analyze individual RCMD particles by SEM-EDX, a recovery method which minimizes potential for thermal and chemical effects on the particles is required.

In the current work, a simple method is demonstrated for recovery of respirable dust from PVC filters by sonication in isopropyl alcohol (IPA) and redeposition onto PC filters for SEM-EDX analysis. IPA was used as no chemical reactions occur with the suspended dust particles and the IPA dries quickly, thus allowing for realistic particle redistribution. Performance was evaluated by comparing the resulting particle size and mineralogy class distributions for recovered samples to results for paired samples that were collected and analyzed directly on PC. A preliminary version of this paper previously appeared in the proceedings of the 19th North American Mine Ventilation Symposium [41]. The preliminary paper presented results for 10 pairs of lab-generated dust samples. Here, the work has been significantly expanded to include 44 pairs of real RCMD samples collected in the field.

2 Materials and Methods

2.1 Lab-Generated Dust Samples

A total of 10 pairs of respirable dust samples were generated in the lab for this study, and each pair consisted of one PC filter and one PVC filter. Four powdered source materials were used in different ratios to create the sample pairs: coal, rock dust, kaolinite, and silica. These materials were chosen to represent the major particle types observed in real RCMD samples [15, 17, 42]. For the coal, a clean coal product was provided by a mine partner and then pulverized to and sieved to minus 230 mesh (< 63 μm) before dust sample generation. The rock dust, which was primarily calcium carbonate, was provided from a real rock dust product provided by a mine partner. It did not need to be pulverized as it was already in a powdered form. For silica dust, MIN-U-SIL® 5 (US Silica, Katy, TX, USA) was used, which is a high-purity silica product with a top size of 5 μm. As a surrogate for aluminosilicates, in general, a high-purity kaolinite powder was used (Ward’s Science, Rochester, NY, USA).

The lab dust samples were generated in a small enclosure per the method described by [43]. Briefly, a small mass (about 1–10 mg) of each source material was placed at the bottom of the enclosure; the ratio between materials was varied for each of the 10 sampling events to achieve different ratios of dust constituents in the samples. The dust materials were aerosolized using short pulses of compressed high-purity air. During each event, two respirable dust samples (i.e., a pair) were collected using standard equipment: an ELF escort air pump (Zefon International, Ocala, FL) was used to pull through a 10-mm Dorr-Oliver nylon cyclone. At 2 L/min, the cyclone cuts out particles larger than about 10 μm and should have a D50 of about 4 μm (i.e., to approximate the respirable convention). The respirable-size particles were collected directly onto filters in 2-piece styrene cassettes. One sample in each pair was collected onto a 37-mm PC filter with track-etched 0.4-μm pores (Zefon International, Ocala, FL, USA), and the other was collected onto 37-mm PVC filter with a nominal 5.0 -μm pore size (Zefon International, Ocala, FL, USA).

2.2 Field Samples of Respirable Coal Mine Dust

A total of 44 pairs of RCMD samples were collected using the same equipment and filter media as described for the lab-generated samples. These field sample pairs were part of a larger inventory that had been collected in 16 underground US coal mines for prior research examining RCMD sources and characteristics [see 17, 43]. Each sample pair was collected in one of five standardized locations in an active section of a mine: in the intake airway, just downwind of the roof bolter, just downwind of the continuous miner or near the longwall midface (“production”), adjacent to the feeder breaker, or in the return airway.

2.3 PVC Filter Sample Dust Recovery and Redeposition

While particle analysis (see below) was done directly on the PC filter from each sample pair, dust on the PVC filter was recovered and redeposited prior to analysis (Fig. 1). Briefly, this procedure was conducted as follows: the PVC filter was submerged in a clean test tube containing IPA; the test tube was sonicated for three minutes at 30 0C to dislodge the dust from the filter; the filter was removed from the test tube; the dust suspension in IPA was pulled through a 47-mm PC filter (track-etched, 0.4-μm pore size) using a vacuum filtration unit; and the PC filter was placed in clean cassette and left overnight to dry completely.

Filter sample preparation procedures (modified from Greth et al. [41])

2.4 Particle Analysis by SEM-EDX

Both the samples from each pair were analyzed by SEM-EDX. From here, the samples collected and analyzed directly on PC filters are termed “direct” (D), with D1-D10 being from the lab-generated sample pairs and D11-D54 being from the field sample pairs. Likewise, the samples collected on PVC and recovered to PC filters are termed “recovered” (R), with R sample numbers matching their D sample pair (e.g., D1 and R1 represent a single sample pair).

All samples were prepared for SEM-EDX analysis by carefully cutting a 9-mm circular subsection from the PC filter using a stainless-steel trephine. The subsection was attached with double-sided tape to aluminum stubs and then sputter coated with a thin layer of Au/Pd to make the samples conductive. SEM-EDX analysis was conducted using an FEI Quanta 600 FEG environmental scanning electron microscope (Hillsboro, OR, USA) which was equipped with backscatter and secondary electron detectors and a Bruker Quantax 400 EDX spectroscope (Ewing, NJ, USA) [17]. Bruker’s Esprit software (version 1.9.4) was used to run an automated routine on each sample to find and analyze particles with length in the range of about 1–10 μm. This “supramicron” routine and instrument settings were described in detail by Sarver et al. [17]; key parameters included an accelerating voltage of 15 kV, 1000x magnification (yielding a frame area of 14,025 μm2), 5.5 spot size, and 12.5-mm working distance. The routine was set to analyze up to 50 particles per field, with fields spaced across the entire stub area, and the objective was to analyze about 500 particles per sample which was nearly always achievable. For each particle, the length and width were recorded, and the elemental spectra were captured. Based on the normalized atomic percentage for eight elements (i.e., C, O, Al, Si, Ca, Mg, Fe, and Ti), each particle was binned using the criteria reported by Sarver et al. [17] into one of eight mineralogy classes: carbonaceous (C), mixed-carbonaceous (MC), aluminosilicates (AS), silica (S), other silicates (SLO), carbonates (CB), heavy minerals (M), or other (O) [17]. Then, the per-particle size and classification data were used to estimate particle distributions for each sample, again following the approach by Sarver et al. [17]. The particle loading density (PLD) of each sample was also estimated as the number of particles observed under the SEM per analyzed area (#/μm2).

3 Results and Discussion

Results for all 10 lab-generated sample pairs and 44 field sample pairs are tabulated in the Supplementary Materials (Tables S1 and Table S2, respectively). For each sample, the percentage (number %) of particles in each mineralogy class is reported, as well as the D50 for the particles in each class and for the sample overall, and the PLD. The D50 represents the median particle length (μm) and the PLD.

Figures 2 and 3 show mineralogy distributions for the lab-generated and field sample pairs, respectively. Visually, there appears to be good agreement between the D and R samples for most of the lab-generated pairs. This indicates the method used to recover particles from the PVC filters and redeposit them on PC for SEM-EDX analysis generally yields a representative sample. To statistically test the agreement between the D and R sample results for each pair, the Freeman-Halton exact test of independence was conducted [44]. Here, the null hypothesis was that the sample mineralogy is independent of whether the dust is analyzed directly or following recovery and redeposition. Thus, for pairs where the null hypothesis is rejected (i.e., p-value < α), the mineralogy results from the D and R samples are interpreted to be in disagreement; conversely, for pairs with p-value > α, the D and R samples are interpreted to be in agreement. p-values for each sample pair are shown in Table 1 for 95% confidence (α = 0.05). Sample pairs with p-values less than 0.05 are in bold. These results confirm that mineralogy distributions were in agreement for seven of the 10 lab-generated pairs, but only 19 of the 44 field sample pairs.

Mineralogy distributions (number % in each class) for the 10 pairs of lab-generated samples. In each pair, the left bar shows the D sample which was directly collected and analyzed on PC, and the right bar shows the R sample which was collected on PVC and recovered to PC for analysis. Pairs for which the Freeman-Halton test yielded a p-value < 0.05 are outlined in red

Mineralogy distributions (number % in each class) for the 44 pairs of field RCMD samples. In each pair, the left bar shows the D sample which was directly collected and analyzed on PC, and the right bar shows the R sample which was collected on PVC and recovered to PC for analysis. Pairs for which the Freeman-Halton test yielded a p-value < 0.05 are outlined in red

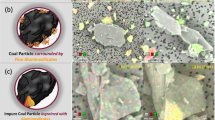

For sample pairs determined to be in disagreement, a close inspection of the mineralogy results (Figs. 2 and 3) reveals this outcome is primarily related to shifts in the percentages of particles reporting to the mineral classes C, MC, AS, and/or CB. C+MC are both interpreted as coal dust; AS is kaolinite in the lab samples but may include other aluminosilicates in the field; and CB is primarily rock dust in the lab but may be source from other carbonates in the field. In a few instances of disagreement (i.e., lab-generated pairs 3 and 5, and field pair 19), the SEM-EDX analysis indicated the D sample had relatively more C+MC content, but less AS than its R counterpart. However, for most of the pairs in disagreement, the D sample had less C+MC, but more AS and/or CB than its R counterpart. When comparing the field samples by location (Fig. 3), there is a discernable difference in the number of sample pairs in disagreement depending on location. The production and bolter location sample pairs were primarily in disagreement, the return location sample pairs were about evenly split, and the intake and feeder samples were primarily in agreement. However, this apparent trend probably has more to do with sample loading than the sampling location itself.

Indeed, for most cases of disagreement, a difference in the PLD values for paired samples seems to be a key factor Fig. 4a, b illustrate this point for the lab-generated and field samples, respectively. For each sample pair, the x-axis in these plots shows the difference in PLD between the D and the R sample—so positive values indicate that the D sample PLD was higher than the R sample PLD. Similarly, the y-axis shows the difference in the percentage of particles in each mineralogy class between the D and the R sample. (Note that only the C+MC, AS, S, SL-O, and CB classes are shown in Fig. 4 since these accounted for nearly all the particles in most samples.) Thus, when the absolute difference in PLD is relatively high (i.e., to the far left or right of the plots), there is a clear tendency for the SEM-EDX analysis to estimate more AS, and less C+MC, for whichever sample in the pair has higher PLD. This tendency can be explained at least in part by the increased likelihood of misclassifying C and MC particles as PLD is increased. In essence, when mineral particles (i.e., typically rich in Al and Si in the case of RCMD) are in close proximity to a coal particle (i.e., typically deficient in Al and Si), the mineral particles can interfere with the EDX spectrum collected on the coal particle, causing it to be classified as AS rather than C or MC. Spatial variability between samplers during initial dust collection could potentially cause differences in PLD. However, at least for the field samples, the clear tendency of D filters to have higher PLD than their R counterparts indicates this is not the primary factor.

Difference in the number percentage of particles in each mineralogy class versus the difference in particle loading density (PLD, #/μm2) for a 10 lab-generated sample pairs b) and 44 field sample pairs. Differences are computed between the results observed for the D and R sample in each pair. Data points for pairs for which the Freeman-Halton test yielded a p-value < 0.05 are outlined in red

Figure 4b shows that large differences in PLD between the D and R field samples were predominantly positive, and this situation was observed most frequently for samples collected in the production and bolter locations. Figure S1 highlights these differences by grouping each dataset into separate plots by location to highlight these PLD differences. This is consistent with the typically higher dust concentration in these versus other locations during sampling [41, 45]. Since field samples were generally collected for similar durations (e.g., 2–4 hrs.), loading was generally highest on the production and bolter samples, followed by the return samples, and then the feeder and intake samples (see Table S2). However, when the dust was recovered and redeposited, the procedure promoted dispersion. This often resulted in lower PLD on the R samples (versus their paired D sample), and probably also broke up agglomerates [46]—though the presence of agglomerates was not explicitly studied here.

The possibility of particle misclassification during SEM-EDX analysis due to high loading has been recently discussed in other studies [41, 45, 46] and could potentially affect particle types other than coal (e.g., silica or carbonates). That said, Fig. 4 indicates that differences in PLD between the D and R samples included in the current work did not have much effect on the classification of particles in the S or CB classes (i.e., the slopes for these trendlines are relatively flat). A slight tendency for D samples to have somewhat more CB than their R counterparts is evident, which could mean that CB particles were somewhat more susceptible to loss during the dust recovery procedure than other particle types.

The D and R sample results were also evaluated with respect to particle size. Figure 5 shows the distribution of D50 values for the lab-generated and field sample pairs. In general, the lab-generated dust tended to be finer than real RCMD collected in the field, which is probably due to the preparation of the source materials that were used for sample generation in the lab. For both sample sets, the R samples visually appear to be finer than the D samples, and a two-sided t-test on the D50 values confirmed statistically significant differences at 95% confidence (i.e., p = 0.0095 for the lab pairs and p < 0.001 for the field sample pairs). This is attributed to deagglomeration during the dust recovery procedure, which includes a brief sonication period in IPA; though differences in particle collection efficiency between the original PVC (dust ultimately analyzed on R samples) and PC filters (dust directly analyzed) cannot be ruled out. Gonzalez et al. [46] demonstrated the deagglomeration phenomenon by using SEM-EDX to evaluate the relative abundance of respirable-sized agglomerates in lab-generated dust as-collected (i.e., directly on the sample filter) and then following recovery in IPA and redeposition. Other studies have also reported somewhat finer distribution of respirable sized dust following sonication [47, 48].

Aside from effects on particle size, it should also be noted that deagglomeration may have had some influence on the classification of particles as mentioned earlier. Consider, for example, an agglomerate containing C and AS particles present on a D sample, whereas the agglomerate might have simply been counted as a single AS particle (i.e., due to the Al and Si content for the whole entity); upon dispersion to create the R sample, the agglomerate’s constituent particles might be counted as separate, relatively finer C and AS particles. This effect might contribute to some extent to the trend shown in Fig. 4b, where the R samples typically have more C+MC than their D sample counterparts. In the current work, any effects of deagglomeration on the paired sample results cannot reliably be separated from the effects of differential PLD. However, the MC class, which falls by its classification criteria between the C and AS classes is expected to be most affected by these phenomena. In samples where AS particles can interfere with C particles—either due to high PLD or agglomeration—the MC class is more likely include misclassified C particles. But in more dispersed samples, there MC class may include a higher proportion of fine, thin AS particles that are misclassified due to penetration of electron beam through the particle (i.e., such that Al and Si content appear relatively low versus larger AS particles). This possibility is evidenced by the particle size data (Table S2), which indicates a mean D50 value of nearly 2.0 μm for MC particles in the D samples versus 1.9 μm for the R samples.

Importantly, while the above implications of particle dispersion are an important consideration for the type of particle-level analysis conducted here, they do not necessarily represent an impediment for other types of analyses that might be targeted on dust samples recovered from fibrous filters. These could include, for instance, bulk analysis of dust using spectroscopic methods. In that case, so long as contamination from the filter media itself is not problematic, the results of this study suggest that a representative sample of respirable dust can be recovered. As such, a future application of the general procedure demonstrated here might be for analysis of RCMD collected by the continuous personal dust monitor (CPDM). Currently, the CPDM is widely used in US coal mines to track RCMD concentration. Although the instrument collects a dust sample to continuously measure mass accumulation, the filter material (fibrous borosilicate glass) and assembly are not suitable for direct-on-filter analysis. However, if the sample could be recovered for analysis, it might enable a better understanding of dust sources and constituents.

4 Conclusion

In the current work, a simple method was demonstrated for recovery of respirable dust particles from a fibrous PVC filter and redeposition to a smooth PC filter to enable particle-level analysis by SEM-EDX. The results generally indicated that this method yields a representative sample of the dust, though particle loading density must be controlled to limit interference between particles during the microscopy analysis. The observed reduction in particle size distributions for recovered samples (versus those analyzed directly) can be attributed to deagglomeration during the recovery procedure. While the impact of this phenomenon on particle classifications could not be quantified here (i.e., any effect was masked by the impact of particle loading density), it is acknowledged that deagglomeration could affect classification of individual particles by SEM-EDX. That said, neither loading density nor deagglomeration is expected to affect bulk particle analysis. Thus, the recovery method demonstrated here might also be applied to support analysis of recovered dust samples by other techniques.

Data Availability

All data related to this study is included in the supplemental information file or available from the corresponding author on reasonable request.

References

World Health Organization (1984) Evaluation of exposure to airborne particles in the work environment. World Health Organization, Geneva

Stanek LW, Sacks JD, Dutton SJ, Dubois JJB (2011) Attributing health effects to apportioned components and sources of particulate matter: an evaluation of collective results. Atmos Environ 45(32):5655–5663. https://doi.org/10.1016/j.atmosenv.2011.07.023

Shekarian Y, Rahimi E, Rezaee M, Su WC, Roghanchi P (2021) Respirable coal mine dust: a review of respiratory deposition, regulations, and characterization. Minerals 11(7):696. https://doi.org/10.3390/min11070696

Kumar P, Kalaiarasan G, Porter AE, Pinna A, Klosowski MM, Demokritou P, Chung KF, Pain C, Arvind DK, Arcucci R, Adcock IM (2021) An overview of methods of fine and ultrafine particle collection for physicochemical characterization and toxicity assessments. Sci Total Environ 756:143553. https://doi.org/10.1016/j.scitotenv.2020.143553

Sioutas C, Delfino RJ, Singh M (2005) Exposure assessment for atmospheric ultrafine particles (UFPs) and implications in epidemiologic research. Environ Health Perspect 113(8):947–955. https://doi.org/10.1289/ehp.7939

Oberdörster G, Oberdörster E, Oberdörster J (2005) Nanotoxicology: an emerging discipline evolving from studies of ultrafine particles. Environ Health Perspect 113(7):823–839. https://doi.org/10.1289/ehp.7339

Ramgolam K, Favez O, Cachier H, Gaudichet A, Marano F, Martinon L, Baeza-Squiban A (2009) Size-partitioning of an urban aerosol to identify particle determinants involved in the proinflammatory response induced in airway epithelial cells. Part Fibre Toxicol 6(1):1–12. https://doi.org/10.1186/1743-8977-6-10

Dalal NS, Newman J, Pack D, Leonard S, Vallyathan V (1995) Hydroxyl radical generation by coal mine dust: possible implication to coal workers’ pneumoconiosis (CWP). Free Radic Biol Med 18(1):11–20

Ross MH, Murray J (2004) Occupational respiratory disease in mining. Occup Med 54(5):304–310. https://doi.org/10.1093/occmed/kqh073

Harrington AD, Hylton S, Schoonen MAA (2012) Pyrite-driven reactive oxygen species formation in simulated lung fluid: Implications for coal workers’ pneumoconiosis. Environ Geochem Health 34(4):527–538. https://doi.org/10.1007/s10653-011-9438-7

Leung CC, Yu ITS, Chen W (2008) Silicosis. The Lancet 379(9830):2008–2018. https://doi.org/10.1016/S0140-6736(12)60235-9

Blackley DJ, Crum JB, Halldin CN, Storey E, Laney AS (2016) Resurgence of progressive massive fibrosis in coal miners—Eastern Kentucky. Morb Mortal Wkly Rep 65(49):1385–1389

NASEM (2018) Monitoring and sampling approaches to assess underground coal mine dust exposures. The National Academies, Washington. https://doi.org/10.17226/25111

Abbasi B, Wang X, Chow JC, Watson JG, Peik B, Nasiri V, Riemenschnitter K, Elahifard M (2021) Review of respirable coal mine dust characterization for mass concentration, size distribution, and chemical composition. Minerals 11(4):426. https://doi.org/10.3390/min11040426

Johann-Essex V, Keleş Ç, Sarver E (2017) A computer-controlled SEM-EDX routine for characterizing respirable coal mine dust. Minerals 7(1):15. https://doi.org/10.3390/min7010015

Sarver E, Keleş Ç, Rezaee M (2019) Characteristics of respirable dust in eight Appalachian coal mines: a dataset including particle size and mineralogy distributions, and metal and trace element mass concentrations. Data in Brief 25:104032. https://doi.org/10.1016/j.dib.2019.104032

Sarver E, Keleş Ç, Afrouz SG (2021) Particle size and mineralogy distributions in respirable dust samples from 25 US underground coal mines. Int J Coal Geol 247:103851. https://doi.org/10.1016/j.coal.2021.103851

Pan L, Golden S, Assemi S, Sime MF, Wang X, Gao Y, Miller J (2021) Characterization of particle size and composition of respirable coal mine dust. Minerals 11(3):276. https://doi.org/10.3390/min11030276

Salinas V, Das M, Jacquez Q, Camacho A, Zychowski K, Hovingh M, Medina A, Rubasinghege G, Rezaee M, Baltrus J, Fairley N, Roghanchi P (2022) Characterization and toxicity analysis of lab-created respirable coal mine dust from the Appalachians and Rocky Mountains Regions. Minerals 12(7):898. https://doi.org/10.3390/min12070898

Hobbie JE, Daley RJ, Jasper S (1977) Use of nuclepore filters for counting bacteria by fluorescence microscopy. Appl Environ Microbiol 33(5):1225–1228

Willis RD, Conner TL (2002) Guidelines for the application of SEM/EDX analytical techniques to particulate matter samples. US Environmental Protection Agency, Washington

Chow JC, Watson JG, Wang X, Abbasi B, Reed WR, Parks D (2022) Review of filters for air sampling and chemical analysis in mining workplaces. Minerals 12(10):1314. https://doi.org/10.3390/min12101314

Jensen PA, Schafer MP (1998) Sampling and characterization of bioaerosols. NIOSH Manual Analytic Methods 1(15):82–112

Kulkarni P, Baron PA, Willeke K (2011) Aerosol measurement: principles, techniques, and applications. John Wiley & Sons, Hoboken

Safety O, Administration H (1999) Personal sampling for air contaminants. OSHA technical manual. US Department of Labor, Washington

National Institute for Occupational Safety and Health (2003) Particulates not otherwise regulated, total. In: NIOSH manual of analytical methods 4th ed. Centers of Disease Control and Prevention, Pittsburgh

National Institute for Occupational Safety and Health (2003) Quartz in coal mine dust, by IR (redeposition). In: NIOSH manual of analytical methods 4th ed. Centers of Disease Control and Prevention, Pittsburgh

Mine Safety & Health Administration (2013) Method No. MSHA P7: infrared determination of quartz in respirable coal mine dust. United States Department of Labor, Pittsburgh

Miller AL, Drake PL, Murphy NC, Noll JD, Volkwein JC (2012) Evaluating portable infrared spectrometers for measuring the silica content of coal dust. J Environ Monit 14:48–55. https://doi.org/10.1039/c1em10678c

Cauda E, Miller A, Drake P (2016) Promoting early exposure monitoring for respirable crystalline silica: taking the laboratory to the mine site. J Occup Environ Hygiene 13(3):D39–D45. https://doi.org/10.1080/15459624.2015.1116691

Miller AL, Weakley AT, Griffiths PR, Cauda EG, Bayman S (2017) Direct-on-filter α-quartz estimation in respirable coal mine dust using transmission Fourier transform infrared spectrometry. Appl Spectroscop 71(5):1014–1024. https://doi.org/10.1177/0003702816666288

Chubb LG, Cauda EG (2022) Direct-on-filter analysis for respirable crystalline silica using a portable FTIR instrument. U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 2022–108, IC 9533, Pittsburgh PA. https://doi.org/10.26616/NIOSHPUB2022108

Lindsley WG, Green BJ, Blachere FM, Martin SB, Law BF, Jensen PA, Schafer MP (2017) Sampling and characterization of bioaerosols. NIOSH Manual Analytic Methods 5(BA):1–115

Stanley NJ, Kuehn TH, Kim SW, Raynor PC, Anantharaman S, Ramakrishnan MA, Goyal SM (2008) Background culturable bacteria aerosol in two large public buildings using HVAC filters as long term, passive, high-volume air samplers. J Environ Monit 10(4):474–481. https://doi.org/10.1039/b719316e

Roper C, Delgado LS, Barrett D, Massey SL, Tanguay RL (2018) PM2.5 filter extraction methods: implications for chemical and toxicological analyses. Environ Sci Technol 53(1):434–442. https://doi.org/10.1021/acs.est.8b04308

Mahdavi A, Siegel JA (2020) Extraction of dust collected in HVAC filters for quantitative filter forensics. Aerosol Sci Technol 54(11):1282–1292. https://doi.org/10.1080/02786826.2020.1774492

Fang T, Verma V, Bates JT, Abrams J, Klein M, Strickland MJ, Sarnat SE, Chang HH, Mulholland JA, Tolbert PE, Russell AG, Weber RJ (2016) Oxidative potential of ambient water-soluble PM 2.5 in the southeastern United States: contrasts in sources and health associations between ascorbic acid (AA) and dithiothreitol (DTT) assays. Atmos Chem Phys 16(6):3865–3879. https://doi.org/10.5194/acp-16-3865-2016

Palmgren UG, Ström GP, Blomquist G, Malmberg P (1986) Collection of airborne micro-organisms on nuclepore filters, estimation and analysis—CAMNEA method. J Appl Microbiol 61(5):401–406

Tuomi T, Kilpikari J, Hartonen M, Kämppi R, Lallukka H (2019) Filter cassette method for analyzing man-made vitreous fibers settled on surfaces. Int J Environ Res Public Health 16(7):1256. https://doi.org/10.3390/ijerph16071256

Kildesø J, Nielsen BH (1997) Exposure assessment of airborne microorganisms by fluorescence microscopy and image processing. The Annals Occup Hygiene 41(2):201–216

Greth A, Afrouz S, Animah F, Keleş Ç, Saver E (2023) Recovery of respirable dust from fibrous filters for particle analysis by scanning electron microscopy. North Am Mine Venti Symp 19:230–238. https://doi.org/10.1201/9781003429241-24

Pokhrel N, Keleş Ç, Jaramillo L, Agioutanti E, Sarver E (2021) Direct-on-filter FTIR spectroscopy to estimate calcite as a proxy for limestone ‘rock dust’ in respirable coal mine dust samples. Minerals 11(9):922. https://doi.org/10.3390/min11090922

Agioutanti E, Keleş Ç, Sarver E (2020) A thermogravimetric analysis application to determine coal, carbonate, and non-carbonate minerals mass fractions in respirable mine dust. J Occup Environ Hygiene 17(2-3):47–58. https://doi.org/10.1080/15459624.2019.1695057

Agresti A (1992) A survey of exact inference for contingency tables. Statis Sci 7:131–153

Keles Ç, Pokhrel N, Sarver E (2022) A Study of respirable silica in underground coal mines: sources. Minerals 12(9):1115. https://doi.org/10.3390/min12091115

Gonzalez J, Keleş Ç, Sarver E (2022) On the occurrence and persistence of coal-mineral microagglomerates in respirable coal mine dust. Min Metal Explor 39(2):271–282

Marín RR, Babick F, Lindner GG, Wiemann M, Stintz M (2018) Effects of sample preparation on particle size distributions of different types of silica in suspensions. Nanomaterials 8(7):454. https://doi.org/10.3390/nano8070454

Marvanová S, Kulich P, Skoupý R, Hubatka F, Ciganek M, Bendl J, Hovorka J, Machala M (2018) Size-segregated urban aerosol characterization by electron microscopy and dynamic light scattering and influence of sample preparation. Atmos Environ 178:181–190. https://doi.org/10.1016/j.atmosenv.2018.02.004

Acknowledgements

Thanks to the industry partners that provided mine access and logistical assistance for dust sampling. All SEM-EDX work for this project was performed at the Nanoscale Characterization and Fabrication Laboratory (NCFL), part of the Institute for Critical Technology and Applied Sciences at Virginia Tech. The authors have no competing interests to declare. All data related to this study is included in the supplemental information file or available from the corresponding author on reasonable request.

Funding

The authors thank the National Institute of Occupational Safety and Health (NIOSH) (contract 75D30119C05529) and the Alpha Foundation for the Improvement of Mine Safety and Health (grant AFCTG20-104) for funding this work. The NCFL is supported by the National Center for Earth and Environmental Nanotechnology Infrastructure and receives funding from the National Science Foundation (ECCS 1542100 and ECCS 2025151).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing Interest

The authors have no competing interests to declare.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

ESM 1

(DOCX 156 kb)

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Greth, A., Afrouz, S.G., Keles, C. et al. Characterization of Respirable Coal Mine Dust Recovered from Fibrous Polyvinyl Chloride Filters by Scanning Electron Microscopy. Mining, Metallurgy & Exploration 41, 1145–1154 (2024). https://doi.org/10.1007/s42461-024-00999-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-024-00999-z