Abstract

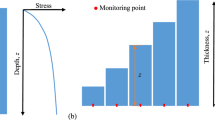

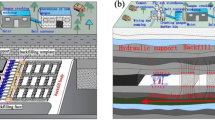

The surface backfill, serving as the operational platform for continuing mining in upward slicing and filling stopes, is required to possess sufficient strength and thickness. Currently, there are limited model methods for determining the strength and thickness of the surface fill body. By analyzing the mechanical actions on the surface backfill, it is determined that its stability is mainly influenced by the combined effects of normal and tangential uniform loads under full-load conditions of trackless equipment. Assuming a circular contact surface between the tire of the trackless equipment and the surface backfill, and utilizing solutions from elastic mechanics theories such as the Boussinesq and Cerruti solution, the stress and displacement distribution of the surface fill body were obtained. Based on the maximum vertical stress condition, where the surface backfill body undergoes maximum deformation while still in an elastic state, and considering the stress–strain relationship, a model for the strength and thickness of the surface backfill has been established. According to the research findings, the design for the strength and structural parameters of the surface backfill has been developed to meet the full-load operation of the Atlas ST7 scooptram, with a compressive strength of 1.32 MPa and a thickness of 0.5 m. Numerical simulation analysis results indicate that the stress and displacement of the surface backfill align with theoretical analysis results. Practical results from industrial application in the western section of the Dahongshan Copper Mine demonstrate that the designed strength and thickness of the surface backfill meet the operational requirements for trackless equipment, resulting in significant engineering application effects and economic benefits. The research findings hold significant importance for advancing the theory of backfill mining and have high applicability and promotional value for similar mines.

Similar content being viewed by others

Data Availability

All relevant data are within the paper.

References

XIE S J (1996) Metal mineral deposit underground mining. Beijing

YU R C (2009) Mining engineer’s handbook. Beijing

WANG Y M (2012) Handbook of modern mining. Beijing

Han ZX, Wang N (2007) Analysis of structural parameters for dipping at high angle and thick orebody with upward horizontal slicing and filling non-pillar continuous mining. Rock Soil Mechanics 28(2):367–370. https://doi.org/10.16285/j.rsm.2007.02.032

Zhang W, Lian MJ, Ren FY, Guo JP, Wang C (2017) Action mechanism of the filling body in the upward-to-horizontal slice stoping-filling method with pointed pillars and shape optimization of pointed pillar. J Mining Safety Eng 34(2):295–301. https://doi.org/10.13545/j.cnki.jmse.2017.02.014

Lai W, Guo QQ, Liu XS, LIU WY (2017) Upward drift filling mining method for unstable and gently inclined thin to medium thick ore body. Nonferrous Metals (Mining Section). 72(04):29–32+47. https://doi.org/10.3969/j.issn.1671-4172.2020.04.005

Han B, Zhang SX, Deng J, Wang XL (2006) Determining method of backfill strength for underhand drift cut-and-fill stopping based on reliability theory. J China Univ Min Technol 03:372–376

Belem T, Benzaazoua M (2008) Design and application of underground mine paste backfill technology. Geotech Geol Eng 26:147–174. https://doi.org/10.1007/s10706-007-9154-3

Son M (2017) Three-dimensional expansion of the terzaghi arching formula considering inclined sliding surfaces and examination of its effects. Int J Geomech 17(07):06016043. https://doi.org/10.1061/(ASCE)GM.1943-5622.0000844

Zhang HQ, Jiao MD, Guo SM, Lei ML, Meng HM (2019) Force analysis & strength design of underground LHD pavement. China Mining Magazine 28(S2):469–473

Yang QP, Wang SY, Liu HB (2019) Study on strength of backfill suitable for operation of large mining equipment. Min Technol 19(06):31–34. https://doi.org/10.13828/j.cnki.ckjs.2019.06.011

Chen Y B (2014) Strength model and application of upward slicing backfill body. Dissertation, Kunming University of Science and Technology

Chen YB, Qiao DP, Sun HS, Yang XH, Lu GY, Li GT (2014) Strength model of the upward horizontal slicing backfill body and its application. Metal Mine 10:27–31

Sun, W, Zhang S Y, Li J X, Li Z Y (2022) Experimental study on energy dissipation of layered backfill under impact load. Construction and Building Materials 347. https://doi.org/10.1016/j.conbuildmat.2022.128478

Li J X, Sun W, Li Q Q, Chen S, Yuan M L, Xia H (2022) Influence of layered angle on dynamic characteristics of backfill under impact loading. Minerals 12(5). https://doi.org/10.3390/min12050511

Gao T, Sun W, Liu Z, Cheng H Y (2022) Investigation on fracture characteristics and failure pattern of inclined layered cemented tailings backfill. Construction and Building Materials 343. https://doi.org/10.1016/j.conbuildmat.2022.128110

Su X F (2003) Study on mechanized panel upward horizontal slicing mining and filling. Dissertation, Central South University

Qiu JP, Guo ZB, Chen C, Xing J, Sun XG (2018) Filling body strength design of the upward drift stoping and filling method. China Mining Magazine 27(11):104–108

Ma SH, Liu J, Zhao PF (2022) Numerical simulation and strength optimization of backfill in Tonglushan mine. Min Technol 22(02):167–170. https://doi.org/10.13828/j.cnki.ckjs.2022.02.031

Xiong CH, Tan YY, Chu LS, Song WD (2022) Study on strength and structure optimization of high-stage subsequent layered cemented backfill. Metal Mine. (03):35–42. https://doi.org/10.19614/j.cnki.jsks.202203003

Yu Y C, Luo Z L, Sun C K, Wei X M (2021) Strength requirement and structure design of cemented backfilling narrow-long stope. Nonferrous Metals(Mining Section) 73(02):21–26

Zhu C M, Zhang W (2009) Structural mechanics. Beijing

Li J P, Lian M J (2011) Mine rock mechanics. Beijing

XU Z L (1990) Elastic mechanics. Beijing

Selvadurai APS (2021) On Boussinesq’s problem. Int J Eng Sci 39:317–322. https://doi.org/10.1016/S0020-7225(00)00043-4

Li J, Berger EJ (2021) A Boussinesq-Cerruti solution set for constant and linear distribution of normal and tangential load over a triangular area. J Elastic Physical Sci Solids 63:137–151. https://doi.org/10.1023/A:1014013425423

Funding

This research was supported by Yunnan Fundamental Research Projects (grant NO.202001AU070062). In addition, part of the funds came from Talent Training Fund of Kunming University of Science and Technology (NO. KKZ3202021040).

Author information

Authors and Affiliations

Contributions

Wang Jun carried out the main writing of the article. Yang Tianyu undertook the numerical simulation part of this paper. Qiao Deng-pan provided technical guidance and review for this article. Xu Peiliang provided the industrial test site and materials for this paper. Zhang Xi has sorted out the references and layout of the article.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, J., Yang, Ty., Qiao, Dp. et al. Strength Model of Surface Backfill in Upward Slicing and Filling Method and Its Application. Mining, Metallurgy & Exploration 41, 997–1011 (2024). https://doi.org/10.1007/s42461-024-00964-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-024-00964-w