Abstract

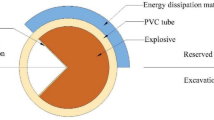

This study investigates the directional blasting of a 90° slit charge structure using laboratory experiments and field tests. A 90° slit charge suitable for the corner of roadway is proposed. After the slit charge blasting, two long main cracks along the slit, and several short secondary cracks in other directions. The slit charge not only significantly reduces damage to the surrounding rock, but also improves the quality of the roadway contour. In addition, a comprehensive damage evaluation system of the roadway contour and the surrounding rock is constructed using digital image analysis, borehole televiewer, and CT scanning.

Similar content being viewed by others

Data Availability

The data used to support the findings of this study are available from the corresponding author upon request.

References

Sayers CM, Kaehanov M (1995) Microcrack-induced elastic wave anisotropy of brittle rocks. J Geophys Res Solid Earth 100(B3):4149–4156

Ramulu M, Chakraborty AK, Sitharam TG (2009) Damage assessment of basaltic rock mass due to repeated blasting in a railway tunnelling project-a case study. Tunn Undergr Space Technol 24(2):208–221

Chen C, Yang R, Ding C, et al. (2021) Design and application of comprehensive experimental system for real imaging-virtual imaging of dynamic caustics. Appl Opt https://doi.org/10.1364/AO.415985

Khademian A, Bagherpour R (2017) Environmentally sustainable mining through proper selection of explosives in blasting operation. Environmental Earth Sciences 76(4):166

Liu W, Yao X, Yang R, et al. (2020) Multi-crack propagation in PMMA plates under dynamic out-of-plane impact. Optics and Lasers in Engineering, 124. https://doi.org/10.1016/j.optlaseng.2019.105849

Zhu Z, Mohanty B, Xie H (2007) Numerical investigation of blasting-induced crack initiation and propagation in rocks. Int J Rock Mech Min Sci 44(3):412–424

Xiao CL, Yang RS, Zuo JJ et al (2023) Influence of open joints on blasting damage and crack propagation of PMMA. Mech Adv Mater Struct. https://doi.org/10.1080/15376494.2023.2171166

Yu LY, Su HJ, Jing HW (2017) Experimental study of the mechanical behavior of sandstone affected by blasting. Int J Rock Mech Min Sci 93:234–241

Yilmaz O, Unlu T (2013) Three dimensional numerical rock damage analysis under blasting load. Tunn Undergr Space Technol 38(9):266–278

Saiang D (2010) Stability analysis of the blast-induced damage zone by continuum and coupled continuum–discontinuum methods. Eng Geol 116(1/2):1–11

Yan C, Xu G, Yang F (2007) Measurement of sound waves to study cumulative damage effect on surrounding rock under blasting load. Chinese J Geotechnic Eng 29(01):88–93

Zhu W, Ming F, Song C (2011) Fractal study of rock damage under blasting loading. Rock Soil Mech 32(10):3131–3135

Yang R S, Xiao C L, Ding C X, et al. (2021) Prediction model of fractal dimensions of rock roadway formation by blasting based on Weibull distribution. Arabian Journal of Geosciences, 14(24). https://doi.org/10.1007/s12517-021-09118-4

Yilmaz O, Unlu T (2013) Three dimensional numerical rock damage analysis under blasting load. Tunnell Underground Space Technol Incorporating Trenchless Technol Res 38(1):266–278. https://doi.org/10.1016/j.tust.2013.07.007

Bird R, Paluszny A, Thomas RN et al (2023) Modelling of fracture intensity increase due to interacting blast waves in three-dimensional granitic rocks. Int J Rock Mech Min Sci 162:105279

Ma GW, An XM (2008) Numerical simulation of blasting-induced rock fractures. Int J Rock Mech Min Sci 45(6):966–975. https://doi.org/10.1016/j.ijrmms.2007.12.002

Wang S, Wei Y (1985) Fracture control in rock blasting. J China Univ Min Technol 14(3):118–125

Yang R, Jiang L, Yang G, et al. (2009) Numerical simulation of directional fracture blasting. Proceedings of the Second International. Conf Modell Simul 3: 296–300

Yue Z, Yang L, Wang Y (2013) Experimental study of crack propagation in polymethyl methacrylate material with double holes under the directional controlled blasting. Fatigue Fract Eng Mater Struct 36(8):827–833

Yue Z, Yang R, Chen G et al (2011) Dynamic test on silt-charge blasting of air-deck charge. J China Coal Soc 36(03):398–402

Ding CX, Yang RS, Xiao CL et al (2022) Directional fracture behavior and stress evolution process of the multi-slit charge blasting. Soil Dyn Earthq Eng 152:107037

Xiao CL, Yang RS, Li Q et al (2022) Experiment on blasting damage and dynamic caustics of jointed medium. Eng Fract Mech 259:108143

Xiao CL, You S, You YY (2022) Research on protective mechanism of semicircular arc pre-crack under impact load. Eng Fract Mech 276(108799):5340

Rossmanith HP, Fourney WL (1982) Fracture initiation and stress wave diffraction at cracked interfaces in layered media I. brittle/brittle transition. Rock Mechanics 14:209–233

Kutter HK, Fairhurst C (1971) On the fracture process in blasting. Int J Rock Mech Min Sci 8(3):181–202

Mandelbrot Benoit B (1983) The fractal geometry of nature. Am J Phys 51(3):286

Katz AJ, Thompson AH (1985) Fractal sandstone pores: implications for conductivity and pore formation. Phys Rev Lett 54(12):1325–1328. https://doi.org/10.1103/PhysRevLett.54.1325

Jarvis NJ (2010) A review of non-equilibrium water flow and solute transport in soil macropores: principles, controlling factors and consequences for water quality. Eur J Soil Sci 58(3):523–546

Liu X, Wang L, Kong X et al (2022) Role of pore irregularity in methane desorption capacity of coking coal. Fuel 314:123037. https://doi.org/10.1016/j.fuel.2021.123037

Paggi M, Carpinteri A (2007) Fractal and multifractal approaches for the analysis of crack-size dependent scaling laws in fatigue. Chaos, Solitons Fractals 40(3):1136–1145. https://doi.org/10.1016/j.chaos.2007.08.068

Zhang YT, Yang RS, Chen C et al (2022) Analysis of the blasting effect of strip cartridge position on jointed rock mass. Mech Adv Mater Struct. https://doi.org/10.1080/15376494.2022.2029982

Roshan H, Li D, Canbulat I et al (2023) Borehole deformation based in situ stress estimation using televiewer data. J Rock Mech Geotech Eng 15(9):2475–2481

Franzosi F, Casiraghi S, Colombo R et al (2023) Quantitative evaluation of the fracturing state of crystalline rocks using infrared thermography. Rock Mech Rock Eng 56(9):6337–6355

Faisal RS, Salih NM, Kamal I et al (2023) X-ray computed tomography (CT) to scan the structure and characterize the mud cake incorporated with various magnetic NPs concentration: an application to evaluate the wellbore stability and formation damage. Nanomaterials 13(12):1843

Funding

This research is supported by the National Natural Science Foundation of China (Grant No. 51934001), the Foundation of State Key Laboratory of Safety and Health for Metal Mines (Grant No. 2021-JSKSSYS-03), and the National Natural Science Foundation of China, Youth Science Fund Project (Grant No. 52204085).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xiao, C., Shi, G., Zhao, Z. et al. Research on Blasting Damage Control of 90° Slit Charge Structure. Mining, Metallurgy & Exploration (2024). https://doi.org/10.1007/s42461-024-00922-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42461-024-00922-6