Abstract

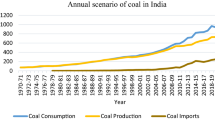

In India, demand for coal exceeds its countrywide supply, despite its natural abundance, due to failure to achieve high production targets, especially in opencast mines, which are responsible for 94.98% of total raw coal production within the country. Employment of technological solutions, such as surface miners, is key to achieving higher coal production and productivity in an eco-friendly manner, especially in the populated areas adjacent to the mining zone and, hence, require restricted blasting operations. It eliminates blast hole drilling, blasting, and primary crushing units, thus reducing related environmental hazards like ground vibration and fly rocks. This paper encompasses the applicability, advantages, constructional features, and performance assessment models for each working mode of a surface miner. The current paper discusses the correlation between coal production and key productivity indicators, namely, machine shift-time, pick, and diesel consumption of surface miner in three different geo-mining conditions. Furthermore, relationships between machine shift-time, pick, and diesel consumption of surface miner and coal production were evaluated through bivariate regression analyses along with their coefficient of determination. These key productivity indicators of surface miner follow polynomial relationships with coal production on a daily and monthly basis, having Pearson correlation values from 0.774 to 0.907 and coefficient of determination, from 0.664 to 0.909 in opencast coal mines.

Similar content being viewed by others

References

Ministry of Power (Govt of India) (2022) Power sector at a glance all India. [Online]. Available: https://powermin.gov.in/en/content/power-sector-glance-all-india. Accessed 6 Jan 2023

Kumar C, Kumaraswamidhas LA, Murthy V, Prakash A (2020) Experimental investigations on thermal behavior during pick-rock interaction and optimization of operating parameters of surface miner. Int J Rock Mech Min Sci 133:104360

Coal India Limited (Govt of India) (2022) Annual Report & Accounts 2020 - 2021. [Online]. Available: https://www.coalindia.in/media/documents/AR_2.pdf. Accessed 6 Jan 2023

Coal Controller (Govt. of India), “Provisional Coal Statistics,” 2022. http://coalcontroller.gov.in/pages/display/20-provisional-coal-statistics (accessed Jan. 06, 2023)

Ministry of Coal (Govt of India). Annual Reports. [Online]. Available: https://coal.gov.in/index.php/en/public-information/reports/annual-reports. Accessed 6 Jan 2023

Ministry of Statistics & Programme Implementation (Govt of India), “Annual Reports,” 2022. https://mospi.gov.in/web/mospi/reports-publications/-/reports/view/templateTwo/8801 (accessed Jan. 06, 2023)

Coal India limited (Govt of India). Annual Report and Accounts. [Online]. Available: https://www.coalindia.in/performance/financial/. Accessed 6 Jan 2023

Pradhan GK, Prakash OM, and Thote NR (2014) “Blast free mining in Indian surface coal mines–current trend,” in Mine Planning and Equipment Selection, Springer, pp. 335–357

Pradhan GK, Dey K (2009) Productivity improvement through selection of operating mode of surface miner: comparative approach. J Mines Met Fuels 57:67–74

AliD (2022) “Advanced Analytics for Surface Mining,” in Advanced Analytics in Mining Engineering, Springer, pp. 169–179

Ghose AK (2008) New technology for surface mining in the 21st century-emerging role for surface miners. J Mines Met Fuels 56:41–43

Dey K, Ghosh AK (2008) Predicting “cuttability” with surface miners-A rockmass classification approach, pp 85–91

Dey K, Bhattacharya J (2012) Operation of surface miner: retrospect of a decade journey in India. Procedia Eng 46:97–104

Volk H-J (2016) Wirtgen drives the development of surface mining. Procedia Eng 138:30–39

Liu P, Zhou W, Cai Q, Shi X, Xu G (2018) The thin coal seam (TCS) mining technology for open pit mines in China. Geotech Geol Eng 36(6):3627–3637

Ivanov VV, Sidorenko SA, Sidorenko AA, Korzhavykh PV (2014) The prospects of introduction of surface miners in technology of development of deposits of contiguous seams of the limestone. Adv Environ Biol 8(13):298–300

Wirtgen Group Company. Application and Planning Guide. [Online]. Available: https://www.wirtgen-group.com/media/02_wirtgen/05_pdfs/praxisratgeber_leseproben/manual_surface-mining_excerpt_en.pdf. Accessed 6 Jan 2023

Bordia SK (1987) Feasibility of introducing continuous systems in surface mines of India. Proceedings of an International Symposium on Continuous Surface Mining Edmonton, Clausthal: Trans Tech Publication, pp 17–20

Zamorano S (2011) Surface ore movement, storage, and recovery systems. SME Mining Eng Handbook 3:977–985

Ghosh AK, Mondal SK, Singh SK, and Sinha A (2010) “Applicability of surface miner in Nongtrai limestone mine Lafarge Umiam Mining Pvt. Ltd,” Meghalaya, India. Central Institute of Mining & Fuel Research (Council of Scientific and Industrial Research). Department of Science & Technology, Government of India. Barwa Road, Dhanbad, vol. 826015

Knezicek T, Petroviae M (2008) Coal quality controlled by Wirtgen surface miners at Gracanica-Gacko pit mine. J Mines Met Fuels 56(3/4):73–74

Aykul H, Yalcin E, Ediz IG, Dixon-Hardy DW, Akcakoca H (2007) Equipment selection for high selective excavation surface coal mining. J South Afr Inst Min Metall 107(3):195–210

Prakash A, Murthy VMSR, Singh KB (2013) Rock excavation using surface miners: An overview of some design and operational aspects. Int J Min Sci Technol 23(1):33–40

Mahanadi Coalfields Limited (Govt of India). Annual Reports. [Online]. Available: https://www.mahanadicoal.in/Financial/annual_report.php. Accessed 6 Jan 2023

South Eastern Coalfields Limited (SECL), “Annual Reports and Accounts.” http://www.secl-cil.in/financial.php (accessed Jan. 06, 2023)

Tatiya RR (2005) Surface and underground excavations: methods, techniques and equipment. CRC Press

Väli E (2011) Best available technology for the environmentally friendly mining with surface miner. TTU Press

Raghavan V, Ariff S, Kumar PP (2021) Determining the Optimum Utilisation of Continuous Miner for Improving Production in Underground Coal Mines. New Visions Sci Technol 9:73–86

Handbook CP (2008) “Edition 38,” Cat® publication by Caterpillar Inc., Peoria, Illinois, USA

Kramadibrata S, Simangunsong GM, Widodo NP, Wattimena RK, Tanjung RA, Wicaksana Y (2015) Rock excavation by continuous surface miner in limestone quarry. Geosyst Eng 18(3):127–139

Dey K, Ghose AK (2011) Review of cuttability indices and a new rockmass classification approach for selection of surface miners. Rock Mech Rock Eng 44(5):601–611

Origliasso C, Cardu M, Kecojevic V (2014) Surface miners: evaluation of the production rate and cutting performance based on rock properties and specific energy. Rock Mech Rock Eng 47(2):757–770

Farmer IW (1986) “Energy based rock characterization,” in Proceedings of International Symposium on Application of Rock Characterization Techniques in Mine Design (ed. Karamis, M.), AIME, Littleton, USA, 17–23

Gehring KH (1992) “Evaluation of Cutting Performance for VASM,” Internal Report BBV, 08–04

Jones IO, and Kramadibrata S (1995) “An excavating power model for continuous surface miners,” in AusIMM Proceedings, 300

Bilgin N, Balcι C, Eskikaya Ş, Ergunalp D (1997) “Full scale and small-scale cutting tests for equipment selection in a celestite mine”, in Mine Planning and Equipment Selection. CRC Press 2020:387–392

Prakash A, Murthy VMSR, Singh KB (2013) Performance simulaton of surface miners with varied machine parameters and rock conditions: Some investigations. J Geol Mining Res 5(1):12–22

Prakash A, Murthy VMSR, Singh KB (2015) A new rock cuttability index for predicting key performance indicators of surface miners. Int J Rock Mech Min Sci 77:339–347

Weihrich H, Koontz H (1993) Management: A global perspective, vol 1. McGraw-Hill College

Acknowledgements

The work presented in this paper forms a part of the Ph.D. work of first author in progress at Indian Institute of Technology (Banaras Hindu University), Varanasi, and thus, the authors acknowledge the support of Department of Mining Engineering, IIT(BHU), for making possible to use different facilities. The authors are also thankful to the management of Gevra, Samleswari, and Lakhanpur project, Coal India Limited, for their encouragement. The views expressed in this paper are those of authors and not necessarily of the organizations they represent.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Singh, N.P., Seervi, V., Kishore, N. et al. An Investigation into Statistical Correlations Between Coal Production and Key Productivity Indicators of Surface Miners in Indian Opencast Mines. Mining, Metallurgy & Exploration 40, 389–402 (2023). https://doi.org/10.1007/s42461-023-00734-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-023-00734-0