Abstract

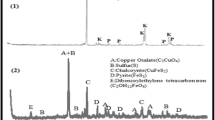

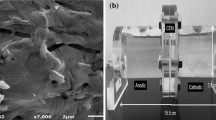

Molybdenite is the most important molybdenum concentrate, which is mainly recovered as a by-product from porphyry copper deposits. Due to the low efficiency of purification processes such as flotation in the reduction of copper content of molybdenum concentrate to a standard level (i.e., less than 0.5 wt.%), further purification by a hydrometallurgical method is required. Although different types of chemical reagents were found to be effective in the leaching of copper minerals from molybdenum concentrate, the mechanisms of these processes remain largely unexplored. In this study, optimal conditions for maximum copper leaching (> 99%) were obtained at the concentration of HCl = 1 M, FeCl3 = 0.5 M, CuCl2 = 0.05 M, CaCl2 = 0.5 M at 75 °C, 500 rpm, and S:L = 1:10 during 60 min. CuCl2 was identified as the most effective leaching reagent for copper dissolution in agreement with Visual MINTEQ model results due to the formation of various types of copper chloride complexes. Furthermore, the electrochemical behaviors of FeCl3, CuCl2, and CaCl2 reagents before and after the leaching process were investigated by the cyclic voltammetry technique. The results of cyclic voltammograms at different scan rates verified the presence of copper chloride complexes, and ferric ions as the oxidizing reagents for better dissolution of copper sulfides. Based on kinetic study results of shrinking core models, both chemical and diffusion reactions controlled the copper leaching process with an obtained activation energy of 33.56 kJ/mol. For recovery of the leached copper, the precipitation process was done by the addition of Na2S at 45 °C, S/Cu = 1, and pH = 9.

Similar content being viewed by others

Data Availability

We mentioned previously in the precipitation process for copper solution after removing from molybdenite concentrate, it is possible for copper to be precipate and separate from soultion, it is a way that would be applicale for copper to recycle from leaching solution and using into the copper extration unite.

References

Abdollahi H, Manafi Z, Shafaei Sied Z, Noaparast M, Manafi Moorkani N (2013) Removal of copper from molybdenite concentrate by mesophilic and extreme thermophilic microorganisms. Int J Min Sci Technol 23(6):827–834

Al-Harahsheh M, Kingman S, Al-Harahsheh A (2008) Ferric chloride leaching of chalcopyrite: synergetic effect of CuCl2. Hydrometallurgy 91(1–4):89–97

Bai S et al (2020) Ammonium chloride catalyze sulfidation mechanism of smithsonite surface: visual MINTEQ models. ToF-SIMS and DFT studies Minerals Engineering 146:106115

Bonan M, Demarthe J, Renon H, Baratin F (1981) Chalcopyrite leaching by CuCl2 in strong NaCI solutions. Metall Trans B 12(2):269–274

Cao Z-F, Zhong H, Qiu Z-H, Liu G-Y, Zhang W-X (2009) A novel technology for molybdenum extraction from molybdenite concentrate. Hydrometallurgy 99(1–2):2–6

Carvalho-Silva VH, Coutinho ND, Aquilanti V (2019) Temperature dependence of rate processes beyond Arrhenius and Eyring: activation and transitivity. Front Chem 7:380

Didyk-Mucha A, Pawlowska A, Sadowski Z (2016) Application of the shrinking core model for dissolution of serpentinite in an acid solution, E3S Web of Conferences. EDP Sciences, pp. 01035

Ebrahimzade H, Khayati GR, Schaffie M (2018) Leaching kinetics of valuable metals from waste Li-ion batteries using neural network approach. J Mater Cycles Waste Manage 20(4):2117–2129

Elgrishi N et al (2018) A practical beginner’s guide to cyclic voltammetry. J Chem Educ 95(2):197–206

Estay H, Barros L, Troncoso E (2021) Metal sulfide precipitation: recent breakthroughs and future outlooks. Minerals 11(12):1385

Fu Y-F et al (2017) Pressure aqueous oxidation of molybdenite concentrate with oxygen. Hydrometallurgy 174:131–139

Fu Y-F et al (2018) Direct extraction of Mo(VI) from acidic leach solution of molybdenite ore by ion exchange resin: batch and column adsorption studies. Trans Nonferrous Metals Soc China 28(8):1660–1669

García-Miranda Ferrari A, Foster CW, Kelly PJ, Brownson DA, Banks CE (2018) Determination of the electrochemical area of screen-printed electrochemical sensing platforms. Biosensors 8(2):53

Gerhardt NI, Palant A, Petrova V, Tagirov R (2001) Solvent extraction of molybdenum (VI), tungsten (VI) and rhenium (VII) by diisododecylamine from leach liquors. Hydrometallurgy 60(1):1–5

Ghahremaninezhad A, Dixon D, Asselin E (2013) Electrochemical and XPS analysis of chalcopyrite (CuFeS2) dissolution in sulfuric acid solution. Electrochim Acta 87:97–112

Gill NS et al (1967) Tetrahalo complexes of dipositive metals in the first transition series. Inorg Synth 9:136–142

He S et al (2019) Kinetics of iron removal from Ti-extraction blast furnace slag by chlorination calcination. Open Chem 17(1):1146–1156

Hsieh M-T, Chen C-T, Whang T-J (2016) Triethanolamine-facilitated one-step electrodeposition of CuAlSe2 thin films and the mechanistic studies utilizing cyclic voltammetry. J Electroanal Chem 762:73–79

Ikumapayi FK (2008) Purification of molybdenite concentrates

Itodo A, Eneji I, Mnenga B, Tseen M (2019) Chemical characterization and leaching kinetics of metals from iron ores. Acad J Chem 4(9):69–80

Kabtamu DM et al (2018) The effect of adding Bi 3+ on the performance of a newly developed iron–copper redox flow battery. RSC Adv 8(16):8537–8543

Kan S, Benzeşik K, Odabaş ÖC, Yücel O (2021) Investigation of molybdenite concentrate roasting in chamber and rotary furnaces. Mining, Metallurgy Exploration 38(3):1597–1608

Khalaghi B et al (2014) Electrochemical behaviour of dissolved iron chloride in KCl+ LiCl+ NaCl melt at 550ºC. ECS Trans 64(4):301

Lasheen T, El-Ahmady M, Hassib H, Helal A (2015) Molybdenum metallurgy review: hydrometallurgical routes to recovery of molybdenum from ores and mineral raw materials. Miner Process Extr Metall Rev 36(3):145–173

Lessard JD, Shekhter LN (2014) Thermodynamic modeling of atmospheric hydrometallurgical removal of chalcopyrite from molybdenite concentrates. Hydrometallurgy 150:9–13

Lewis AE (2010) Review of metal sulphide precipitation. Hydrometallurgy 104(2):222–234

Li Y, Kawashima N, Li J, Chandra A, Gerson AR (2013) A review of the structure, and fundamental mechanisms and kinetics of the leaching of chalcopyrite. Adv Coll Interface Sci 197:1–32

Lundström M, Aromaa J, Forsén O (2009) Redox potential characteristics of cupric chloride solutions. Hydrometallurgy 95(3–4):285–289

Lundström M, Aromaa J, Forsén O, Hyvärinen O, Barker MH (2007) Cathodic reactions of Cu2+ in cupric chloride solution. Hydrometallurgy 85(1):9–16

Malhotra D, Rowe RM, Bhasin AK (1986) Evaluation of collectors for molybdenite flotation. Mining, Metallurgy Exploration 3(3):184–186

Manukyan K, Davtyan D, Bossert J, Kharatyan S (2011) Direct reduction of ammonium molybdate to elemental molybdenum by combustion reaction. Chem Eng J 168(2):925–930

Nadimi H, Sarpoolaky H, Soltanieh M (2021) Formation reaction kinetics of nanocrystalline TiC via molten LiCl–KCl applying shrinking core model. Ceram Int 47(9):12859–12869

Nazim M, Ameen S, Akhtar MS, Shin H-S (2019) Electrochemical detection of chloride ions by copper (II) complex with mixed ligand of oxindole derivative and dithiocarbamates moiety. Appl Sci 9(7):1358

Nicol M, Miki H, Zhang S (2017) The anodic behaviour of chalcopyrite in chloride solutions: Voltammetry. Hydrometallurgy 171:198–205

Nicol MJ, Tjandrawan V, Zhang S (2016) Cathodic reduction of iron (III) and copper (II) on various sulfide minerals in chloride solutions. Hydrometallurgy 166:113–122

Nozari I, Azizi A (2020) Experimental and kinetic modeling investigation of copper dissolution process from an Iranian mixed oxide/sulfide copper ore. J Sustain Metallurgy 6(3):437–450

Ojeda M, Rivarola J, Quiroga O (2002) Study on chlorination of molybdenum trioxide mixed with carbon black. Miner Eng 15(8):585–591

Padilla R, Letelier H, Ruiz MC (2013a) Copper removal from molybdenite by sulfidation-leaching process, materials processing fundamentals. Springer, pp. 217–223

Padilla R, Letelier H, Ruiz MC (2013) Kinetics of copper dissolution in the purification of molybdenite concentrates by sulfidation and leaching. Hydrometallurgy 137:78–83

Pestryak I, Morozov V, Baatarhuu J (2013) Improvement of copper–molybdenum ore beneficiation using a combined flotation and biohydrometallurgy method. Int J Min Sci Technol 23(1):41–46

Prasad PM, Balasubramanian K, Mukhopadyay R (2007) Separation chemistry in the refining of an off-grade molybdenite concentrate by leaching with an acid mix. Mining, Metallurgy Exploration 24(2):97–104

Rahimi Borujerdi P, Shotorban B, Mahalingam S, Weise DR (2019) Modeling of water evaporation from a shrinking moist biomass slab subject to heating: Arrhenius approach versus equilibrium approach. Int J Heat Mass Transf 145:118672

Rasulova S, Guro V, Safarov E, Adinaev X (2020) Metals recovery from molybdenite concentrate by electrooxidation and leaching, IOP Conference Series: Materials Science and Engineering. IOP Publishing, pp. 012076

Rukini A, Rhamdhani MA, Brooks GA, Van den Bulck A (2022) Metals production and metal oxides reduction using hydrogen: a review. J Sustain Metallurgy 8(1):1–24

Schueler TA, de Aguiar PF, Vera YM, Goldmann D (2021) Leaching of Cu, Zn, and Pb from sulfidic tailings under the use of sulfuric acid and chloride solutions. J Sustain Metallurgy 7(4):1523–1536

Sun X, Yuan W, Jin K, Zhang Y (2021) Control of the redox potential by microcontroller technology: researching the leaching of chalcopyrite. Minerals 11(4):382

Timoshevsky A, Yemel’Kin V, Pozdnyakov B, Zasypkin I (2006) Plasma-thermal decomposition of molybdenite, equipment and experiment. Thermophys Aeromechanics 13(4):609–614

Velásquez-Yévenes L, Nicol M, Miki H (2010) The dissolution of chalcopyrite in chloride solutions: part 1. Effect Solution Potential Hydrometallurgy 103(1–4):108–113

Vračar RŽ, Parezanović IS, Cerović KP (2000) Leaching of copper (I) sulfide in calcium chloride solution. Hydrometallurgy 58(3):261–267

Wilkomirsky I, Becker J, Parada F (2022) Molybdenite concentrate purification by a continuous sulfation-leaching process. Mining, Metallurgy & Exploration

Yin Z et al (2016) Investigation into the flotation response of refractory molybdenum ore to depressant mixtures: a case study. Int J Min Sci Technol 26(6):1089–1094

Yoo K et al (2010) Effect of chloride ions on leaching rate of chalcopyrite. Miner Eng 23(6):471–477

Youcai L, Hong Z, Zhanfang C (2011) Molybdenum removal from copper ore concentrate by sodium hypochlorite leaching. Mining Sci Technol (China) 21(1):61–64

Funding

This research is financially supported by a research grant of the Sahand University of Technology (grant number 19316) and Sungun copper mine complex (grant number 3099109).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Barakan, S., Aghazadeh, V., Bidari, E. et al. Comprehensive Electrochemical-Chemical Study of Copper Reduction from Molybdenum Concentrate Using Mixed HCl, FeCl3, CuCl2, and CaCl2 Leaching Medium. Mining, Metallurgy & Exploration 40, 141–159 (2023). https://doi.org/10.1007/s42461-022-00708-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-022-00708-8