Abstract

Phosphate ores upgraded by flotation are widely used as vital raw materials for the sustainable production of phosphate fertilizers to maintain the food supply. High-grade phosphate reserves become more and more depleted. Low-grade phosphate mining and processing are in the spotlight of the fertilizer industries to cope with the exponential growth in the world’s population and meet the increased demand for fertilizers. As part of a series of research works conducted within a major project aiming at upgrading a low-grade phosphate ore never-exploited before, the present work endeavors to optimize the flotation of this ore using the response surface method (RSM) as a follow-up of a screening study. Unveiling new insights on such a strategy paved the way for improving flotation performances. This work demonstrated that an optimum 30.18% P2O5 with 88.07% recovery was achieved using 63.10 g/t of sodium alginate (NaAL) and 2484.72 g/t of sodium oleate (NaOL) at pH 11.40. This maximum was contrasted with a new formulation of fatty acids (FAM). The 30.76% P2O5 grade with a recovery of 89.72% was attained using 50.94 g/t of NaAL and 1455.40 g/t of FAM at pH 11.68. FAM collector markedly outperformed NaOL at low concentrations proving the efficiency of synergists.

Similar content being viewed by others

References

Ros MBH, Hiemstra T, van Groenigen JW, Chareesri A, Koopmans GF (2017) Exploring the pathways of earthworm-induced phosphorus availability. Geoderma 303:99–109. https://doi.org/10.1016/j.geoderma.2017.05.012

Wesana J, De Steur H, Dora MK, Mutenyo E, Muyama L, Gellynck X (2018) “Towards nutrition sensitive agriculture actor readiness to reduce food and nutrient losses or wastes along the dairy value Chain in Uganda. J Cleaner Prod 182:46–56. https://doi.org/10.1016/j.jclepro.2018.02.021

Chowdhury RB, Moore GA, Weatherley AJ, Arora M (2014) A review of recent substance flow analyses of phosphorus to identify priority management areas at different geographical scales. Resour Conserv Recycl 83:213–228. https://doi.org/10.1016/j.resconrec.2013.10.014

Cheng C, Huang Z, Zhang R, Zhou J, Liu Z, Zhong H, Wang H, Kang Z, He G, Yu X, Ren Z, Qiu T, Hu Y, Fu W (2020) Synthesis of an emerging morpholine-typed gemini surfactant and its application in reverse flotation carnallite ore for production of potash fertilizer at low temperature. J Clean Prod 261:121121. https://doi.org/10.1016/j.jclepro.2020.121121

Calle-Castañeda SM, Márquez-Godoy MA, Hernández-Ortiz JP (2018) Phosphorus recovery from high concentrations of low-grade phosphate rocks using the biogenic acid produced by the acidophilic bacteria Acidithiobacillus thiooxidans. Miner Eng 115:97–105. https://doi.org/10.1016/j.mineng.2017.10.014

de Oliveira P, Mansur H, Mansur A, da Silva G, Clark Peres AE (2019) Apatite flotation using pataua palm tree oil as collector. J Market Res 8(5):4612–4619. https://doi.org/10.1016/j.jmrt.2019.08.005

de Araujo FHA, Bejan L, Stosic B, Stosic T (2020) An analysis of Brazilian agricultural commodities using permutation – information theory quantifiers: the influence of food crisis. Chaos, Solitons Fractals 139:110081. https://doi.org/10.1016/j.chaos.2020.110081

Liu C, Zhang W, Li H (2019) Selective flotation of apatite from calcite using 2-phosphonobutane-1,2,4-tricarboxylic acid as depressant. Miner Eng 136:62–65. https://doi.org/10.1016/j.mineng.2019.03.003

Pan Z, Wang Y, Wei Q, Chen X, Jiao F, Qin W (2020) Effect of sodium pyrophosphate on the flotation separation of calcite from apatite. Sep Purif Technol 242:116408. https://doi.org/10.1016/j.seppur.2019.116408

Ruan He, Chi. (2019) “Review on beneficiation techniques and reagents used for phosphate ores. Minerals 9(4):253. https://doi.org/10.3390/min9040253

Mohammadkhani M, Noaparast M, Shafaei SZ, Amini A, Amini E, Abdollahi H (2011) Double reverse flotation of a very low grade sedimentary phosphate rock, rich in carbonate and silicate. Int J Miner Process 100(3):157–165. https://doi.org/10.1016/j.minpro.2011.06.001

Dong X, Siqing L, Yanqing Y, Hailin L, Yi P (2017) A review on new technological progress for beneficiation of refractory phosphate ore in China. IOP Conference Series: Earth and Environ Sci 63:012043. https://doi.org/10.1088/1755-1315/63/1/012043

Jafari M, Chehreh Chelgani S, Pourghahramani P, Ebadi H (2018) Measurement of collector concentrations to make an efficient mixture for flotation of a low grade apatite. Measurement 121:19–25. https://doi.org/10.1016/j.measurement.2018.02.037

Hernáinz F, Calero M, Blázquez G (2004) Flotation of low-grade phosphate ore. Adv Powder Technol 15(4):421–433. https://doi.org/10.1163/1568552041270491

Cao Q, Cheng J, Wen S, Li C, Bai S, Liu D (2015) A mixed collector system for phosphate flotation. Miner Eng 78:114–121. https://doi.org/10.1016/j.mineng.2015.04.020

Gharabaghi M, Irannajad M, Noaparast M (2010) A review of the beneficiation of calcareous phosphate ores using organic acid leaching. Hydrometallurgy 103(1–4):96–107. https://doi.org/10.1016/j.hydromet.2010.03.002

Abouzeid A-ZM, Negm AT, Elgillani DA (2009) Upgrading of calcareous phosphate ores by flotation: effect of ore characteristics. Int J Miner Process 90(1–4):81–89. https://doi.org/10.1016/j.minpro.2008.10.005

Zhou, F., Liu, Q., Liu, X., Li, W., Feng, J., and Chi, R. 2020 “Surface electrical behaviors of apatite, dolomite, quartz, and phosphate ore.” Frontiers in Materials, Vol. 7,https://doi.org/10.3389/fmats.2020.00035.

Gao Z, Fan R, Ralston J, Sun W, Hu Y (2019) Surface broken bonds: an efficient way to assess the surface behaviour of fluorite. Miner Eng 130:15–23. https://doi.org/10.1016/j.mineng.2018.09.024

Aleksandrova, T., Elbendari, A., and Nikolaeva, N. 2020 “Beneficiation of a low-grade phosphate ore using a reverse flotation technique.” Mineral Processing and Extractive Metallurgy Review, pp. 1–6. https://doi.org/10.1080/08827508.2020.1806834.

Cao Q, Zou H, Chen X, Wen S (2019) Flotation selectivity of n-hexadecanoylglycine in the fluorapatite–dolomite system. Miner Eng 131:353–362. https://doi.org/10.1016/j.mineng.2018.11.033

Karlkvist T, Patra A, Rao KH, Bordes R, Holmberg K (2015) Flotation selectivity of novel alkyl dicarboxylate reagents for apatite–calcite separation. J Colloid Interface Sci 445:40–47. https://doi.org/10.1016/j.jcis.2014.11.072

Cao Q, Cheng J, Wen S, Li C, Liu J (2016) Synergistic effect of dodecyl sulfonate on apatite flotation with fatty acid collector. Sep Sci Technol 51(8):1389–1396. https://doi.org/10.1080/01496395.2016.1147467

Filippova IV, Filippov LO, Duverger A, Severov VV (2014) Synergetic effect of a mixture of anionic and nonionic reagents: ca mineral contrast separation by flotation at neutral PH. Miner Eng 66–68:135–144. https://doi.org/10.1016/j.mineng.2014.05.009

Cheng R, Li C, Liu X, Deng S (2017) Synergism of octane phenol polyoxyethylene-10 and oleic acid in apatite flotation. Physicochemical Problems of Mineral Processing 53(2):1214–1227. https://doi.org/10.5277/ppmp170241

Ruan Y, Deng B, He D, Chi R (2021) Synergetic effect of cottonseed fatty acid salt and nonionic surfactant NP-4 in the froth flotation of siliceous-calcareous phosphate rock. Colloids Surf, A 622:126650. https://doi.org/10.1016/j.colsurfa.2021.126650

Huang QM, Huang JJ, Zhou H, Pan ZQ, Chi RA (2011) Synthesis and application of α-chloro oleic acid monoester floating collector. Advanced Materials Research 233–235:596–599. https://doi.org/10.4028/www.scientific.net/AMR.233-235.596

Chen W, Feng Q, Zhang G, Yang Q, Zhang C (2017) The effect of sodium alginate on the flotation separation of scheelite from calcite and fluorite. Miner Eng 113:1–7. https://doi.org/10.1016/j.mineng.2017.07.016

Dong L, Wei Q, Qin W, Jiao F (2020) “Selective adsorption of sodium polyacrylate on calcite surface: implications for flotation separation of apatite from calcite. Separation and Purification Technology 241:116415. https://doi.org/10.1016/j.seppur.2019.116415

Wang T, Feng B, Guo Y, Zhang W, Rao Y, Zhong C, Zhang L, Cheng C, Wang H, Luo X (2020) The flotation separation behavior of apatite from calcite using carboxymethyl chitosan as depressant. Miner Eng 159:106635. https://doi.org/10.1016/j.mineng.2020.106635

Dong, L., Wei, Q., Jiao, F., and Qin, W. 2020 “Utilization of polyepoxysuccinic acid as the green selective depressant for the clean flotation of phosphate ores.” Journal of Cleaner Production a, p.124532. https://doi.org/10.1016/j.jclepro.2020.124532.

Yang, B., Cao, S., and Zhu, Z. 2020 “Selective flotation separation of apatite from dolomite utilizing a novel eco-friendly and efficient depressant for sustainable manufacturing of phosphate fertilizer.” Journal of Cleaner Production, p. 11. https://doi.org/10.1016/j.jclepro.2020.124949.

Zhong C, Feng B, Zhang W, Zhang L, Guo Y, Wang T, Wang H (2020) The role of sodium alginate in the flotation separation of apatite and dolomite. Powder Technol 373:620–626. https://doi.org/10.1016/j.powtec.2020.07.007

Zhong C, Feng B, Zhang L, Zhang W, Wang H, Gao Z (2022) Flotation separation of apatite and calcite using gum arabic as a depressant. Colloids Surf, A 632:127723. https://doi.org/10.1016/j.colsurfa.2021.127723

Yang B, Zhu Z, Sun H, Yin W, Hong J, Cao S, Tang Y, Zhao C, Yao J (2020) Improving flotation separation of apatite from dolomite using pams as a novel eco-friendly depressant. Miner Eng 156:106492. https://doi.org/10.1016/j.mineng.2020.106492

Yang B, Yin W, Zhu Z, Sun H, Sheng Q, Fu Y, Yao J, Zhao K (2021) Differential adsorption of hydrolytic polymaleic anhydride as an eco-friendly depressant for the selective flotation of apatite from dolomite. Sep Purif Technol 256:117803. https://doi.org/10.1016/j.seppur.2020.117803

Zeng, M., Yang, B., Zhang, H., and Jia, F. “A green depressant iminodisuccinic acid (IDS) for apatite-dolomite separation and its interaction mechanism.” Minerals Engineering, Vol. 175, 2022, p. 107276. LIU.

Abdel-Khalek NA (2000) Evaluation of flotation strategies for sedimentary phosphates with siliceous and carbonates gangues. Miner Eng 13(7):789–793. https://doi.org/10.1016/S0892-6875(00)00064-9

Lisiansky, L., Baker, M., Larmour-Ship, K., and Elyash, O. “A tailor made approach for the beneficiation of phosphate rock.” Engineering Conferences International ECI Digital Archives. In Beneficiation of Phosphates, 2015.

Huang Z, Cheng C, Liu Z, Zeng H, Feng B, Zhong H, Luo W, Hu Y, Guo Z, He G, Fu W (2019) Utilization of a new gemini surfactant as the collector for the reverse froth flotation of phosphate ore in sustainable production of phosphate fertilizer. J Clean Prod 221:108–112. https://doi.org/10.1016/j.jclepro.2019.02.251

Boujlel H, Daldoul G, Tlil H, Souissi R, Chebbi N, Fattah N, Souissi F (2018) The beneficiation processes of low-grade sedimentary phosphates of Tozeur-Nefta deposit (Gafsa-Metlaoui Basin: South of Tunisia). Minerals 9(1):2. https://doi.org/10.3390/min9010002

Aarab I, Derqaoui M, Abidi A, Yaacoubi A, El Amari K, Etahiri A, Baçaoui A (2020) Direct flotation of low-grade Moroccan phosphate ores: a preliminary micro-flotation study to develop new beneficiation routes. Arab J Geosci 13(23):1252. https://doi.org/10.1007/s12517-020-06279-6

Aarab, I., Derqaoui, M., El Amari, K., Yaacoubi, A., Abidi, A., Bacaoui, A., and Etahiri, A. The challenging passage through micro-flotation to mechanical flotation cell: case of low-grade Moroccan phosphates. Germany, 2020.https://doi.org/10.33422/2nd.research.2020.09.233

Ruan Y, Zhang Z, Luo H, Xiao C, Zhou F, Chi R (2018) Effects of metal ions on the flotation of apatite, dolomite and quartz. Minerals 8(4):141. https://doi.org/10.3390/min8040141

Eskanlou A, Huang Q, Foucaud Y, Badawi M, Romero AH (2022) Effect of Al3+ and Mg2+ on the flotation of fluorapatite using fatty- and hydroxamic-acid collectors – a multiscale investigation. Appl Surf Sci 572:151499. https://doi.org/10.1016/j.apsusc.2021.151499

Wang R, Lu Q, Sun W, Lin S, Han H, Sun W, Wei Z (2022) Flotation separation of apatite from calcite based on the surface transformation by fluorite particles. Miner Eng 176:107320. https://doi.org/10.1016/j.mineng.2021.107320

Aarab, I., Derqaoui, M., El Amari, K., Yaacoubi, A., Abidi, A., Etahiri, A., and Baçaoui, A. 2021 “Influence of surface dissolution on reagents’ adsorption on low-grade phosphate ore and its flotation selectivity.” Colloids and Surfaces A: Physicochemical and Engineering Aspects, p. 127700. https://doi.org/10.1016/j.colsurfa.2021.127700.

Horta D, de Mello Monte MB, deSalles Leal Filho, e L. (2016) The effect of dissolution kinetics on flotation response of apatite with sodium oleate. International Journal of Mineral Processing 146:97–104. https://doi.org/10.1016/j.minpro.2015.12.003

Li H, Chen Y, Zheng H, Huang P, Yang P, Chen Q, Weng X, He D, Song S (2021) Effect of geological origin of apatite on reverse flotation separation of phosphate ores using phosphoric acid as depressant. Miner Eng 172:107182. https://doi.org/10.1016/j.mineng.2021.107182

Komar, K., S., and J.T, C. Beneficiation of phosphate Ore. Society for Mining, Metallurgy, and Exploration, 2013.

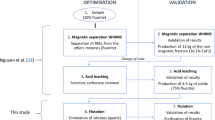

Aarab I, Derqaoui M, Amari KE, Yaacoubi A, Abidi A, Etahiri A, Baçaoui A (2022) Flotation tendency assessment through DOE: case of low-grade Moroccan phosphate ore. Mining, Metallurgy & Exploration 39(4):1721–1741. https://doi.org/10.1007/s42461-022-00647-4

Rodrigues AJ, Brandao PRG (1993) The influence of crystal chemistry properties on the floatability of apatites with sodium oleate. Miner Eng 6(6):643–653. https://doi.org/10.1016/0892-6875(93)90118-7

Funding

The authors gratefully acknowledge the financial support of the R&D Initiative—Call for projects around phosphates APPHOS—sponsored by OCP Foundation, R&D OCP, Mohammed VI Polytechnic University, National Center of Scientific and Technical Research CNRST, and Ministry of Higher Education, Scientific Research and Professional Training of Morocco MESRSFC (TRT-BAC-01/2017).

Author information

Authors and Affiliations

Contributions

Imane Aarab: conceptualization, methodology, validation, formal analysis and investigation, data curation, writing—original draft, and writing—review and editing. Khalid El Amari: supervision, methodology, and writing—review and editing. Abdelrani Yaacoubi: supervision, methodology, and writing—review and editing. Abdelaziz Baçaoui: project administration and funding acquisition. Abderahman Etahiri: resources and writing—review and editing.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Aarab, I., Amari, K.E., Yaacoubi, A. et al. Optimization of the Flotation of Low-Grade Phosphate Ore Using DOE: a Comparative Evaluation of Fatty Acid Formulation to Sodium Oleate. Mining, Metallurgy & Exploration 40, 95–108 (2023). https://doi.org/10.1007/s42461-022-00706-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-022-00706-w