Abstract

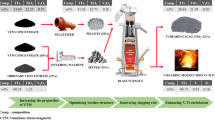

Decreasing copper content in slag is critical for improving copper recovery, where apparent viscosity is the main factor affecting the separation of matte/copper from the slag. The viscous behavior of copper converter slag was investigated during reduction process in this paper, and its non-Newtonian viscous behavior and shear thickening characteristics were clarified. The effects of silicate structure and solid particles in the melt on the slag apparent viscosity were investigated. As slag cleaning proceeded in an electric furnace, the magnetite gradually transformed into ferrous oxide, increasing the FeO/SiO2 ratio. With this ratio increased from 1.2 to 2.0, the slag structure was simplified, and its apparent viscosity decreased from 0.26 to 0.12 Pa·s at 1523 K. The iron phase was excessively reduced to metallic state; the slag contained metallic copper-iron alloy particles, increasing apparent viscosity. The apparent viscosity and phase structure of the slag corresponding to the iron phase reduction process were analyzed in detail; the results obtained in the present study are of great significance to the reasonable control of the converter copper slag cleaning process.

Similar content being viewed by others

References

Tan P (2011) Modeling and control of copper loss in smelting slag. JOM 63:51–57. https://doi.org/10.1007/s11837-011-0207-y

Cardona NCP, Vargas J et al (2013) The physical chemistry of copper smelting slags and copper losses at the paipote smelterPart 2 -characterisation of industrial slags. Can Metall Q 50:330–340. https://doi.org/10.1179/000844311X13112418194806

Hidayat T, Henao HM, Hayes PC, Jak E (2012) Phase equilibria studies of Cu-O-Si systems in equilibrium with air and metallic copper and Cu-Me-O-Si systems (Me=Ca, Mg, Al, and Fe) in equilibrium with metallic copper. Metall Mater Trans B 43:1290–1299. https://doi.org/10.1007/s11663-012-9735-2

Wilde ED, Bellemans I, Campforts M, Guo M, Blanpain B, Moelans N, Verbeken K (2016) Investigation of high-temperature slag/copper/spinel interactions. Metall Mater Trans B 47:3421–3434. https://doi.org/10.1007/s11663-016-0805-8

Coursol P, Mackey PJ, Kapusta JPT, Valencia NC (2015) Energy consumption in copper smelting: a new Asian horse in the race. JOM 67:1066–1074. https://doi.org/10.1007/s11837-015-1380-1

Chen P, Xiao H, Chen J, Chen L, Zhang D, Liu W, Yang T (2020) Oxygen-rich side-blown bath smelting of copper dross: a process study. J Sust Metallurgy 6:344–354. https://doi.org/10.1007/s40831-020-00278-3

Cardona N, Mackey PJ, Parra R (2011) Physical chemistry of copper smelting slags and copper losses at the Paipote smelterPart 1 -thermodynamic modelling. Can Metall Q. 50:318–329. https://doi.org/10.1179/000844311X13112418194761

Coursol P, Valencia NC, Mackey P, Bell S, Davis B (2012) Minimization of copper losses in copper smelting slag during electric furnace treatment. JOM 64:1305–1313. https://doi.org/10.1007/s11837-012-0454-6

Sridhar R, Toguri JM, Simeonov S (1997) Copper losses and thermodynamic considerations in copper smelting. Metall Mater Trans B 28:191–200. https://doi.org/10.1007/s11663-997-0084-5

Demetrio S, Ahumada SA, Durán MÁ et al (2000) Slag cleaning: the Chilean copper smelter experience. JOM 52:20–25. https://doi.org/10.1007/s11837-000-0168-z

Zhou S, Wei Y, Li B, Wang H (2018) Effect of iron phase evolution on copper separation from slag via coal-based reduction. Metall Mater Trans B 49:3086–3096. https://doi.org/10.1007/s11663-018-1379-4

Zhou H, Li B, Wei Y, Wang H, Mclean A (2019) Magnetite reduction in copper converter slag using biodiesel produced from waste cooking oil. Can Metall Q 58:187–195. https://doi.org/10.1080/00084433.2018.1540088

Wang L, Wei Y, Zhou S, Li B, Wang H (2021) Matte separated behavior from slag during the cleaning process by using waste cooking oil as carbon neutral reductant. J. Min. Metall. Sect B 57:379–388. https://doi.org/10.2298/JMMB210407034W

Srivastava U, Kawatra SK, Eisele TC (2013) Production of pig iron by utilizing biomass as a reducing agent. Int J Miner Process 119:51–57. https://doi.org/10.1016/j.minpro.2012.12.008

Luo S, Yi C, Zhou Y (2011) Direct reduction of mixed biomass-Fe2O3 briquettes using biomass-generated syngas. Renewable Energy 36:3332–3336. https://doi.org/10.1016/j.renene.2011.05.006

Guo Z, Zhu D, Pan J, Yao W, Xu W, Chen J (2017) Effect of Na2CO3 addition on carbothermic reduction of copper smelting slag to prepare crude Fe-Cu alloy. JOM 69:1688–1695. https://doi.org/10.1007/s11837-017-2410-y

Kaiura GH, Toguri JM, Marchant G (1977) Viscosity of fayalite-based slags. Can Metall Q 16:156–160. https://doi.org/10.1179/cmq.1977.16.1.156

Ishibashi H (2009) Non-Newtonian behavior of plagioclase-bearing basaltic magma: subliquidus viscosity measurement of the 1707 basalt of Fuji volcano. J Volcanol Geotherm Res 181:78–88. https://doi.org/10.1016/j.jvolgeores.2009.01.004

Luo S, Cheng Y, Chen Q (2014) Metal material rheology. Mechanical industry publishing house, BeiJing

Liu Z, Zhang L, Malfliet A, Blanpain B, Guo M (2018) Non-Newtonian behavior of solid-bearing silicate melts: an experimental study. J Non-Cryst Solids 493:65–72. https://doi.org/10.1016/j.jnoncrysol.2018.04.042

Kline J, Tangstad M, Tranell G (2015) A Raman spectroscopic study of the structural modifications associated with the addition of calcium oxide and boron oxide to silica. Metall Mater Trans B 46:62–73. https://doi.org/10.1007/s11663-014-0194-9

Park JH (2013) Structure & roperty relationship of CaO-MgO-SiO2 slag: quantitative analysis of Raman spectra. Metall Mater Trans B 44:938–947. https://doi.org/10.1007/s11663-013-9825-9

Mysen BO, Finger LW, Virgo D, Seifert FA (1982) Curve-fitting of Raman spectra of silicate glasses. American Mineralogist 67:686–695. https://doi.org/10.1016/0040-1951(83)90053-7

Mysen BO, Virgo D, Scarfe CM (1980) Relations between the anionic structure and viscosity of silicate melts; a Raman spectroscopic study. Am Miner 74:290–301. https://doi.org/10.0000/PMID15469

Park JH (2012) Structure-property correlations of CaO-SiO2-MnO slag derived from Raman spectroscopy. Isij International 52:1627–1636. https://doi.org/10.2355/isijinternational.52.1627

Mills KC (1993) The influence of structure on the physico-chemical properties of slags. ISIJ Int 33:148–155. https://doi.org/10.2355/isijinternational.33.148

Choi JS, Park TJ, Min DJ, Sohn I (2021) Viscous behavior of high-FetO-bearing slag systems in relation to their polymeric structural units. J Mater Res Technol 15:1382–1394. https://doi.org/10.1016/j.jmrt.2021.08.126

Kim TS and Park JH(2020)Thermodynamics of iron redox equilibria and viscosity-structure relationship of CaO-Al2O3-FetO melts. J.Non-Cryst.Solids 542:120089. https://doi.org/10.1016/j.jnoncrysol.2020.120089

Kim TS and Park JH(2022)Influence of Al2O3 and SiO2 on the structure and viscosity of iron-compound bearing calcium-aluminosilicate slags. J Alloys Compd 916:165328. https://doi.org/10.1016/j.jallcom.2022.165328

Kucharski M, Stubina NM, Toguri JM (1989) Viscosity measurements of molten Fe-O-SiO2, Fe-O-CaO-SiO2, and Fe-O-MgO-SiO2 slags. Can Metall Q 28:7–11. https://doi.org/10.1179/000844389795401701

Shiraishi Y, Ikeda K, Tamura A, Saito T (1978) On the viscosity and density of the molten FeO-SiO2 system. Transactions of the Japan Institute of Metals 19:264–274. https://doi.org/10.2320/matertrans1960.19.264

Lee YS, Min DJ, Jung SM, Yi SH (2004) Influence of basicity and FeO content on viscosity of blast furnace type slags containinG FeO. ISIJ Int 44:1291–1297. https://doi.org/10.2355/isijinternational.44.1283

Zhang R, Wang Y, Zhao X, Jia J, Liu C, Min Y (2020) Structure and viscosity of molten CaO-SiO2-FexO slag during the early period of basic oxygen steelmaking. Metall Mater Trans B 51:2021–2029. https://doi.org/10.1007/s11663-020-01888-8

Li Q, Gao J, Zhang Y, An Z, Guo Z (2017) Viscosity measurement and structure analysis of Cr2O3-bearing CaO-SiO2-MgO-Al2O3 slags. Metall Mater Trans B 48:346–356. https://doi.org/10.1007/s11663-016-0858-8

Fu C (1993) Non-ferrous metallurgy principle. Metallurgical industry publishing house, BeiJing

Lopasso EM, Caro M, Caro A, Turchi PE (2003) Phase diagram of an empirical potential: the case of Fe-Cu - art. Physica B 68:214205. https://doi.org/10.1103/PhysRevB.68.214205

Funding

This work was supported by the National Natural Science Foundation of China (51974142 and 52104396) and Autonomous project of State Key Laboratory of Complex Nonferrous Metal Resources Clean Utilization (CNMRCUTS2104).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ye, Z., Dai, G., Zhang, B. et al. Apparent Viscosity Evolution of Copper Converter Slag During a Reduction Process. Mining, Metallurgy & Exploration 39, 2529–2538 (2022). https://doi.org/10.1007/s42461-022-00697-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-022-00697-8