Abstract

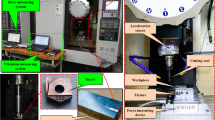

The main target of this research is to examine the performance characteristics of uncoated and coated tungsten carbide-cobalt rock cutting bits on their calculated output responses in cutting operation. This research aims to optimize the process variables like cutting speed, cutting depth and coating material while considering multiple output responses such as resultant cutting forces, specific energy, wear rate, quantity of material removed and angle of resultant reaction forces during rock cutting operation. This study also determines the effect of cutting parameters on quality measures during lab-scale linear rock cutting operation. Sputter coated aluminum titanium nitride, titanium aluminum silicon nitride and uncoated cutting bits were used for this study. Taguchi orthogonal array has been considered as the design of experiment based on the operating variables and their levels for the current research. In this study, grey relation grade and fuzzy logic combined with the Taguchi design of experiments i.e., multi-objective hybrid optimization technique, were employed. Grey relational analysis was used to optimize the process variables and then fuzzified by means of the Mamdani fuzzy engine. Finally, Taguchi analysis was used to optimize the obtained output responses. The parameter combination of cutting speed: 200 mm/s, cutting depth: 6 mm and titanium aluminum silicon nitride coating was found to be the optimum input variables to obtain the best performance results. Validation of the hybrid optimization approach was executed through the confirmatory test analysis.

Similar content being viewed by others

Data Availability

All data generated or analyzed during this study are included in this article.

Code Availability

Not applicable.

References

Karakurt I (2014) Application of Taguchi method for cutting force optimization in rock sawing by circular diamond saw blades. Sadhana 39(5):1055–1070

Mishnaevsky L (1998) Rock fragmentation and optimization of drilling tools, In: Fracture of Rock, Chapter 6, 167–203.

Galang Sandy Prayogo, Nuraini Lusi (2016) Application of Taguchi technique coupled with grey relational analysis for multiple performance characteristics optimization of EDM parameters on ST 42 steel. AIP Conf Proc 1725, 020061.

Phadke MS (1989) Quality engineering using robust design. Prentice Hall, Englewood Cliffs, NJ

Pandaa AK, Singhb R (2013) Optimization of process parameters by Taguchi method: Catalytic degradation of polypropylene to liquid fuel. Int J Multidiscip Curr Res 4:50–54

Puri Y M and Deshpande N V (2004) Simultaneous optimization of multiple quality characteristics of WEDM based on fuzzy logic and Taguchi technique,” Proc. of the Fifth Asia Pacific Industrial Engineering and Management System Conference, (2004), pp. 14.18.1–14.18.12.

Lin JL, Lin CL (2005) The use of grey-fuzzy logic for the optimization of the manufacturing process. J Mater Process Technol 160:9–14

Abdelmoneim ME, Scrutton R (1973) The tribology of cutting tools during finish machining. Wear 25:45–53

Boing D, de Oliveira AJ, Schroeter RB (2018) Limiting conditions for application of PVD (TiAlN) and CVD (TiCN/Al2O3/TiN) coated cemented carbide grades in the turning of hardened steels. Wear 416–417:54–61. https://doi.org/10.1016/j.wear.2018.10.007

Gupta KM, Ramdev K, Dharmateja S, Sivarajan S (2018) Cutting characteristics of PVD coated cutting tools. Mater Today 5:11260–11267. https://doi.org/10.1016/j.matpr.2018.02.092

Jindal P, Santhanam A, Schleinkofer U, Shuster A (1999) Performance of PVD TiN, TiCN, and TiAlN coated cemented carbide tools in turning. Int J Refract Hard Mat 17:163–170

Serra R, Chibane H, Duchosal A (2018) Multi-objective optimization of cutting parameters for turning AISI 52100 hardened steel. Int J Adv Manuf Tech 99:2025–2034. https://doi.org/10.1007/s00170-018-2373-3

Touggui Y, Belhadi S, Mechraoui S-E, Uysal A, Yallese MA, Temmar M (2020) Multi-objective optimization of turning parameters for targeting surface roughness and maximizing material removal rate in dry turning of AISI 316L with PVD-coated cermet insert. SN Appl Sci 2:1360

Palanikumar K, Latha B, Senthilkumar V, Davim JP (2012) Analysis on drilling of glass fiber–reinforced polymer (GFRP) composites using grey relational analysis. Mater Manuf Process 27:297–305

Shivakoti I, Kibria G, Pradhan PM, Pradhan BB, Sharma A (2019) ANFIS based prediction and parametric analysis during turning operation of stainless steel 202. Mater Manuf Process 34:112–121

Ahilan C, Kumanan S, Sivakumaran N (2010) Application of grey based Taguchi method in multi-response optimization of turning process. Adv Prod Eng Manag 5:171–180

Asiltürk I, Neşeli S (2012) Multi response optimisation of CNC turning parameters via Taguchi method-based response surface analysis. Measurement 45:785–794

Karunya G, Ravikumar P, Krishna P, Krishna P (2017) Optimization of the surface roughness by applying the Taguchi technique for the turning of AISI 304 austenitic stainless steel. Int J Mech Eng Technol 8:694–701

Khare SK, Agarwal S (2017) Optimization of machining parameters in turning of AISI 4340 Steel under cryogenic condition using Taguchi technique. Procedia CIRP 63:610–614

Dewangan S, Biswas CK (2013) Optimisation of machining parameters using grey relation analysis for EDM with impulse flushing. Int J Mechatron Manuf Syst 6:144–158

Nalbant M, Gökkaya H, Sur G (2007) Application of Taguchi method in the optimization of cutting parameters for surface roughness in turning. Mater Des 28:1379–1385

Nian C, Yang W, Tarng Y (1999) Optimization of turning operations with multiple performance characteristics. J Mater Process Technol 95:90–96

Tzeng C-J, Lin Y-H, Yang Y-K, Jeng M-C (2009) Optimization of turning operations with multiple performance characteristics using the Taguchi method and Grey relational analysis. J Mater Process Technol 209:2753–2759

Abburi N, Dixit U (2007) Multi-objective optimization of multipass turning processes. Int J Adv Manuf Tech 32:902–910

Asiltürk I, Akkuş H (2011) Determining the effect of cutting parameters on surface roughness in hard turning using the Taguchi method. Measurement 44:1697–1704

Sardinas RQ, Santana MR, Brindis EA (2006) Genetic algorithm-based multi-objective optimization of cutting parameters in turning processes. Eng Appl Artif Intell 19:127–133

Das B, Roy S, Rai R, Saha S (2016) Application of grey fuzzy logic for the optimization of CNC milling parameters for Al–4.5% Cu–TiC MMCs with multi-performance characteristics. Int J Eng Sci Technol 19:857–865

Liu S, Li Y, Liao Y, Guo Z (2014) Structural optimization of the cross-beam of a gantry machine tool based on grey relational analysis. Struct Multidiscip Optim 50:297–311

Shankar S, Mohanraj T, Thangarasu SK (2016) Multi-response milling process optimization using the Taguchi method coupled to grey relational analysis. Mater Test 58:462–470

Shankar S, Mohanraj T, Rajasekar R (2019) Prediction of cutting tool wear during milling process using artificial intelligence techniques. Int J Comput Integr Manuf 32:174–182

Sathiya P, Jaleel MYA, Katherasan D, Shanmugarajan B (2011) Optimization of laser butt welding parameters based on the orthogonal array with fuzzy logic and desirability approach. Struct Multidiscip Optim 44:499–515. https://doi.org/10.1007/s00158-010-0615-6

Moganapriya C, Rajasekar R, Ponappa K, Venkatesh R, Jerome S (2018) Influence of coating material and cutting parameters on surface roughness and material removal rate in turning process using Taguchi method. Mater Today 5:8532–8538

Ahilan C, Kumanan S, Sivakumaran N (2009) Multi-objective optimisation of CNC turning process using grey based fuzzy logic. Int J Mach Mach Mater 5:434–451

Moganapriya C, Rajasekar R, Sathish Kumar P, Mohanraj T, Gobinath VK, Saravanakumar J (2021) Achieveing machining effectiveness for AISI 1015 structural steel through coated inserts and grey-fuzzy coupled taguchi optimization approach. Struct Multidiscip Optim 63:1169–1186

Moganapriya C, Rajasekar R, Ponappa K, Venkatesh R, Karthick R (2017b) Influence of cutting fluid flow rate and cutting parameters on the surface roughness and flank wear of TiAlN coated tool in turning AISI 1015 steel using Taguchi method. Arch Metall Mater 62:1827–1832

Klir G, Yuan B (1995) Fuzzy sets and fuzzy logic, vol 4. Prentice Hall, New Jersey

Senthilkumar N, Sudha J, Muthukumar V (2015) A grey-fuzzy approach for optimizing machining parameters and the approach angle in turning AISI 1045 steel. Adv Prod Eng Manag 10:195–208

Krishankant JT, Bector M, Kumar R (2012) Application of Taguchi method for optimizing turning process by the effects of machining parameters. Int J Eng Adv Rechnol 2:263–274

Moganapriya C, Rajasekar R, Ponappa K, Karthick R, Perundurai RV, Kumar PS, Pal SK (2017a) Tribomechanical behavior of TiCN/TiAlN/WC-C multilayer film on cutting tool inserts for machining. Mater Test 59:703–707

Acknowledgements

The authors are grateful to the Department of Mining Engineering, IIT Kharagpur and Department of Mechanical Engineering, Kongu Engineering College to execute the work and allowed to use their facilities. The corresponding author thanks the Ministry of Human Resource Development for providing a scholarship to carry out the research work.

Author information

Authors and Affiliations

Contributions

All authors discussed the content of the article, based on their domain expertise on the subjects presented. Sathish Kumar Palaniappan and Moganapriya Chinnasamy performed the experiments and analyzed the data through statistical approach. Sathish Kumar Palaniappan drafted the first version of the paper. Moganapriya Chinnasamy and Gobinath Velu Kaliyannan checked and revised the manuscript. Samir Kumar Pal and Rajasekar Rathanasamy supervised the study and discussed the results, proofread the manuscript, and confirmed its findings. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics Approval

Authors followed the ethical standards.

Consent to Participate

Not applicable.

Consent for Publication

This manuscript does not contain any individual person’s data in any form.

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Palaniappan, S.K., Pal, S.K., Chinnasamy, M. et al. Multi-response Optimization for Evaluating Output Responses in Rock Cutting Through Grey-Fuzzy-Coupled Taguchi Technique. Mining, Metallurgy & Exploration 39, 1133–1148 (2022). https://doi.org/10.1007/s42461-022-00603-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-022-00603-2