Abstract

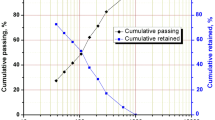

The type and dosage of flocculants used in the middle thickener of the copper-molybdenum plant, in addition to adjusting the quality of recycled process water, is very effective on the floatability of molybdenite. In this study, the effect of starch-based flocculant (wheat starch) was investigated on the efficiency of middle thickener and molybdenite flotation, in the molybdenum processing plant. First, sampling from overflow and underflow of the middle thickener in Mo processing circuit (in industrial scale), in the presence and absence of starch, were collected. The polished sections of samples from the overflow and underflow of the thickener were studied in order to determine the effect of starch on particles settling with different shapes. Microscopic studies show that molybdenite plate-like coarse particles are transferred to the thickener overflow (process water) in the presence of starch flocculant, whereas molybdenite fine particles present in the underflow are often needle-shaped. In addition, in terms of grade distribution, the grade of molybdenum in the thickener overflow is higher than that of copper and iron. Then, after sedimentation tests (in laboratory scale) with different concentrations of flocculant, flotation tests were performed on test samples. According to the results from laboratory studies, increasing the dosage of starch from 0 to 1000 g/t increased the recovery of molybdenite flotation and reduced the access of copper minerals to molybdenite concentrate. In this case, molybdenum recovery (in lab tests) is increased by about 5% compared to the case of not using starch. While the increase in the recovery of molybdenum by adding starch to the middle thickener in the industrial scale is about 10%. In higher dosages of starch (2000 g/t), the trend is reversed (in the lab and industrial scale) and molybdenum recovery decreased sharply due to the decrease in contact angle and depression, whereas the amount of copper transferred to the molybdenum concentrate increased.

Similar content being viewed by others

References

Castro S, Lopez-Valdivieso A, Laskowski JS (2016) Review of the flotation of molybdenite. Part I: Surface properties and floatability. International Journal of Mineral Processing. https://doi.org/10.1016/j.minpro.2016.01.003

Castro S, Laskowski JS (2015) Depressing effect of flocculants on molybdenite flotation. Miner Eng. https://doi.org/10.1016/j.mineng.2014.12.027

Beaussart A, Parkinson L, Mierczynska-Vasilev A, Beattie DA (2012) Adsorption of modified dextrins on molybdenite: AFM imaging, contact angle, and flotation studies. J Colloid Interface Sci. https://doi.org/10.1016/j.jcis.2011.10.075

Lopez-Valdivieso A, Madrid-Ortega I, Reyes-Bahena JL, Sánchez-López AA, Song S (2006) Propiedades de la interface molibdenita/solución acuosa y su relación con la flotabilidad del mineral. Proc. In XVI Congreso Internacional de Metalurgia Extractiva, Saltillo-México. 226–235 (Spanish text).

Miller JD, Lin CL, Chang SS (1984) Coadsorption phenomena in the separation of pyrite from coal by reverse flotation. Coal Prep. https://doi.org/10.1080/07349348408945537

Castro S, Laskowski JS (2004) Molybdenite depression by shear degraded polyacrylamide solutions. In: Laskowski, J.S. (Ed.), Particle Enlargement in Mineral Processing – Proc. 5th UBC-McGill Symp., Hamilton, MetSoc of CIM. 169–178.

Kar B, Sahoo H, Rath SS, Das B (2013) Investigations on different starches as depressants for iron ore flotation. Miner Eng. https://doi.org/10.1016/j.mineng.2013.05.004

Wei G, Li H, Ren Y, Zhao F, Song S (2015) Flocculation of pyrite fines in aqueous suspensions with corn starch to eliminate mechanical entrainment in flotation. Minerals. https://doi.org/10.3390/min5040515

Shrimali K, Atluri V, Wang Y, Bacchuwar S, Wang X, Miller JD (2018) The nature of hematite depression with corn starch in the reverse flotation of iron ore. J Colloid Interface Sci. https://doi.org/10.1016/j.jcis.2018.04.002

Yang S, Li C, Wang L (2017) Dissolution of starch and its role in the flotation separation of quartz from hematite. Powder Technol. https://doi.org/10.1016/j.powtec.2017.07.061

Bulut G, Ceylan A, Soylu B, Goktepe F (2011) Role of starch and metabisuphite on pure pyrite and pyritic copper ore flotation. Physicochemical Problems of Mineral Processing. https://hdl.handle.net/20.500.12462/8667.

Xia L, Zhong H, Liu G, Wang S (2009) Utilization of soluble starch as a depressant for the reverse flotation of diaspore from kaolinite. Miner Eng. https://doi.org/10.1016/j.mineng.2009.01.007

Hey W (1985) The influence of surface-active agents in washing water on flotation and flocculation. In: Wilkinson JK (ed) Coal Prep. Balkema, pp 127–140

Bahrami A, Ghorbani Y, Hosseini MR, Kazemi F, Abdollahi M, Danesh A (2018) Combined effect of the operating parameters on separation efficiency and kinetics of the copper flotation. Mining, Metallurgy and Exploration. https://doi.org/10.1007/s42461-018-0005-y

Abdollahi M (2019) The Effect of texture and mineralogy on flotation recovery of molybdenite at the Sungun copper complex /concentrator plant. Master of Science Thesis in Mining Engineering – Mineral Processing, Urmia University.

Dogu I, Arol AI (2004) Separation of dark-colored minerals from feldspar by selective flocculation using starch. Powder Technol. https://doi.org/10.1016/j.powtec.2003.11.009

Han G, Wen S, Wang H, Feng Q (2019) Effect of starch on surface properties of pyrite and chalcopyrite and its response to flotation separation at low alkalinity. Miner Eng. https://doi.org/10.1016/j.mineng.2019.106015

Ahmadi M, Mahdi G, Hadi A (2018) Effects of type and dosages of organic depressants on pyrite floatability in microflotation system. Adv Powder Technol. https://doi.org/10.1016/j.apt.2018.08.015

Mu YF, Peng YJ, Lauten RA (2016) The depression of pyrite in selective flotation by different reagent systems – a Literature review. Miner Eng. https://doi.org/10.1016/j.mineng.2016.06.018

Dippenaar A (1982) The destabilization of froth by solids I The mechanism of film rupture. Int J Min Process. https://doi.org/10.1016/0301-7516(82)90002-3

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bahrami, A., Danesh, A., Kazemi, F. et al. The Evaluation of Starch-Based Flocculant on the Thickener Operation in the Molybdenum Processing Plant and Competency of Molybdenite Flotation. Mining, Metallurgy & Exploration 39, 1255–1266 (2022). https://doi.org/10.1007/s42461-022-00578-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-022-00578-0