Abstract

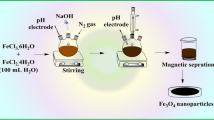

Bayan Obo ore contains mainly bastnaesite, monazite and associated iron, fluorite, calcite, dolomite, barite, and trace amount of columbite. Due to its complex mineral compositions and similar mineral properties, it is difficult to separate and obtain rare earth and fluorite concentrates with high purity by conventional magnetic separation and flotation. In this paper, a stepwise magnetic separation process comprised of wet permanent magnetic separation (PMS), wet electromagnetic separation (EMS), and superconducting magnetic separation (SCMS) was proposed to pre-concentrate iron, rare earth, and fluorite minerals from Bayan Obo ore. The results showed that iron, rare earth, and fluorite preconcentrates with high purity and low impurity content could be achieved, which might be helpful to shorten the technological process and improve the separation efficiency for the subsequent flotation of iron, rare earth, and fluorite minerals.

Similar content being viewed by others

References

Gupta CK, Krishnamurthy N (1992) Extractive metallurgy of rare earths. Int Mater Rev 37(5):197–248

Huang Y, Zhang T, Dou Z, Liu J, Tang F (2014) Study on leaching rare earths from bastnaesite treated by calcification transition. J Rare Earths 32(11):1043–1047

Chen Z (2011) Global rare earth resources and scenarios of future rare earth industry. J Rare Earths 29(1):1–6

Faris N, Ram R, Tardio J, Bhargava S, McMaster S, Pownceby M (2017) Application of ferrous pyrometallurgy to the beneficiation of rare earth bearing iron ores -A review. Miner Eng 110:20–30

Kanazawa Y, Kamitani M (2006) Rare earth minerals and resources in the world. J Alloys Compd 408:1339–1343

Gupta CK, Krishnamurthy N (2005) Extractive metallurgy of rare earths. CRC Press, Boca Raton

Li L, Yang X (2016) China’s Rare Earth Resources, Mineralogy, and Beneficiation. In: Rare Earths Industry. Elsevier B V, Amsterdam

Fuerstenau DW, Pradip H-UR (1992) The surface chemistry of bastnaesite, barite and calcite in aqueous carbonate solutions. Colloids Surf A Physicochem Eng Asp 68(1):95–102

Cao Z, Cao Y, Qu Q, Zhang J, Mu Y (2019) Separation of bastnäsite from fluorite using ethylenediamine tetraacetic acid as depressant. Miner Eng 134:134–141

Xu J, Xiong D, Song S, Chen L (2018) Superconducting pulsating high gradient magnetic separation for fine weakly magnetic ores: cases of kaolin and chalcopyrite. Results Phys 10:837–840

Svoboda J, Fujita T (2003) Recent developments in magnetic methods of material separation. Miner Eng 16(9):785–792

Li Y, Wang J, Wang X, Wang B, Luan Z (2011) Feasibility study of iron mineral separation from red mud by high gradient superconducting magnetic separation. Physica C Supercond 471(3-4):91–96

Okada S, Mishima F, Akiyama Y, Nishijima S (2011) Fundamental study on recovery of resources by magnetic separation using superconducting bulk magnet. Physica C Supercond 471(21-22):1520–1524

Zhang H, Zhao Z, Xu X, Li L (2011) Study on industrial wastewater treatment using superconducting magnetic separation. Cryogenics 51(6):225–228

Zhao Y, Xi B, Li Y, Wang M, Zhu Z, Xia X, Zhang L, Wang L, Luan Z (2012) Removal of phosphate from wastewater by using open gradient superconducting magnetic separation as pretreatment for high gradient superconducting magnetic separation. Sep Purif Technol 86:255–261

Jordens A, Sheridan RS, Rowson NA, Waters KE (2014) Processing a rare earth mineral deposit using gravity and magnetic separation. Miner Eng 62:9–18

Xiong D, Lu L, Holmes RJ (2015) Developments in the physical separation of iron ore. In: Iron Ore. Woodhead Publishing

Yang H, Rong Y, Tang R, Xue X, Li Y (2013) Recovery of iron from Baotou rare earth tailings by magnetizing roast. Rare Metals 32(6):616–621

Acknowledgments

The study was financially supported by the National Natural Science Foundation of China (51764045), Open Foundation of State Key Laboratory of Mineral Processing (BGRIMM-KJSKL-2020-23), Inner Mongolia Natural Science Foundation (2020LH05027, 2019MS05039), Inner Mongolia Young Science & Technology Talent Support Plan (NJYT-18-B08), Innovation Fund project of Inner Mongolia University of Science and Technology (2019QDL-B18), and Inner Mongolia Major Basic Research Open Project (0406091701).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, J., Zu, P., Yi, S. et al. Preconcentration of Iron, Rare Earth, and Fluorite from Bayan Obo Ore Using Superconducting Magnetic Separation. Mining, Metallurgy & Exploration 38, 701–712 (2021). https://doi.org/10.1007/s42461-020-00305-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-020-00305-7