Abstract

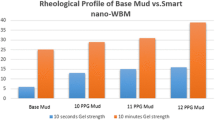

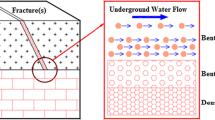

Bentonite represents one of the main players in the stability of the drilling mud. Its particle size and particle size distribution affect the physical properties of the drilling mud especially the rheological properties. Therefore, a specific particle size distribution was recommended by American Petroleum Institute (API) for use in drilling mud. To clarify the effect of individual size and size distribution, in this study, the bentonite sample was classified into different size fractions. Each size fraction was tested separately in terms of controlling properties such as filtration loss, plastic viscosity, gel strength, cake thickness, and packing density. The effect of each size fraction on the rheological properties of the suspension was correlated to the behavior of the whole particle size distribution in the bentonite sample. The results indicate that the coarser the particles, the higher the rheological properties; in this case, the API mixture is the highest. The filtration loss and cake thickness for the API mixture are lower than that of the individual size fractions due to its wider size distribution due to the filling of voids between larger particles with smaller ones, which lead to bed compaction and consequently lower fluid loss and cake thickness.

Similar content being viewed by others

References

Abdou MI, Ahmed HE (2011) Effect of particle size of bentonite on rheological behavior of the drilling mud. Pet Sci Technol 29:2220–2233

Abdou MI, Al-Sabagh AM, Dardir MM (2013) Evaluation of Egyptian bentonite and nano-bentonite as drilling mud. Egypt J Pet 22:53–59

Ahn J, Jung J (2017) Effects of fine particles on thermal conductivity of mixed silica sands. Appl Sci 7(70):650–662

Dhiman AS (2012) Rheological properties & corrosion characteristics of drilling mud additives. M.Sc. thesis, Faculty of Engineering, Dalhousie University, Halifax, Nova Scotia, Canada

Fennis SAM, Walraven JC, Uijl JA (2013) Defined-performance design of ecological concrete. Mater Struct 46(4):639–650

Iman M, Kamal H (2018) Understanding the role of particle packing characteristics in rheophysical properties of cementitious suspensions: a literature review. Constr Build Mater 161:340–353

Iyasara AC, Ovri JE (2015) Corrosion behaviour and effects of drilling mud. Int J Sci Res Eng Technol 4(9):917–923

Paysson Y (2004) Solid/liquid dispersions in drilling and production. Oil Gas Sci Technol 59(1):11–21

Praveen K, Vikas M, Saxena1 V. (2014) Emulsion based drilling fluids: an overview. Int J ChemTech Res 6(4):2306–2315

Specification for Drilling Fluids – Specifications and Testing (2010) API Specification 13A 18th Edition, Purchasing Guidelines Handbook, American Petroleum Institute

Veblen DR, Guthrie GD, Livi KJT, Reynolds RC (1990) High-resolution transmission electron microscopy and electron diffraction of mixed-layer illite/smectite: experimental results. Clays Clay Min 38:1–13

Weian H, Yee-Kwong L, Ting C, Pek-Ing A, Xianhua L (2016) Surface chemistry and rheological properties of API bentonite drilling fluid: pH effect, yield stress, zeta potential and ageing behavior. J Petrol Sci Eng 146(10):561–569

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Farag, R.M., Salem, A.M., El-Midany, A.A. et al. Justifying API Bentonite Rheological Behavior Through Its Forming Size Fractions. Mining, Metallurgy & Exploration 37, 537–542 (2020). https://doi.org/10.1007/s42461-019-00157-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-019-00157-w