Abstract

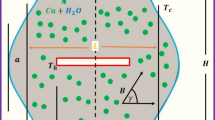

The Falcon concentrator is capable of separating minerals in fine size classes based on their differential density. Separation of mineral particles depends upon the fluid flow characteristics and relative movement of particles in a fluid. In the present study, a fluid flow characteristic inside the Falcon concentrator was established through experimentation and modeling. The Falcon concentrator has two fluid entry points: (a) Fluid entering through gravity assisted feeding system and (b) Fluid entering through the fluidized hole on the concentrator wall. In order to identify the role of fluid entering the concentrator, a tracer was injected into the system. As per the tracer based experimentation, it was established that fluid entering through the gravity based feeding system is responsible for thin flowing film formation in the stratification zone where particles are stratified based on their relative density. The momentum balance and continuity equations were simplified for a high centrifugal force field, and the fluid velocity profile was estimated inside the thin flowing film. Estimated fluid flow profiles will help to simulate the particle trajectories inside the Falcon concentrator. The influence of rotational speed, fluid flow rate, and cone angle on the fluid velocity profile were investigated. Fluid thickness over the concentrator wall is also estimated, and it is typically of the order of ~150–200 μm.

Similar content being viewed by others

References

Traore A, Conil P, Houot R, Save M (1995) An evaluation of the Mozley MGS for fine particle gravity separator. Miner Eng 8(7):767–778

McAlister S (1992) Case studies in the use of the Falcon gravity concentrator. 24th Annual Canadian Mineral Processor Conference, Ottawa

Lins FF, Veiga MM, Stewart JA, Papalia A, Papalia R (1992) Performance of a new centrifuge (Falcon) in concentrating a gold from Texada Island, B.C., Canada. Min Eng 5(10–12):1113–1121

Liu Q, Cui Z, Etsell TH (2006) Pre-concentration and residual bitumen removal from Athabasca oilsands froth treatment tailings by a Falcon centrifugal concentrator. Int J Miner Process 78:220–230

Farag MZ, Abdel-Khalek NA, Hassan MS, El Aref MM, Manawi AWE (2012) Upgrading of Egyptian nonsulfide zinc ore by gravity separation techniques. J Metal Eng 1(1):6–13

Oruç F, Özgen S, Sabah E (2010) An enhanced-gravity method to recover ultra-fine coal from tailings: Falcon concentrator. Fuel 89:2433–2437

Boylu F (2013) Modeling of free and hindered settling conditions for fine coal beneficiation through a Falcon Concentrator. Int J Coal Prep Util 33:277–289

Zhang B, Yang F, Akbari H, Mohanty MK, Brodzik P, Latta P, Hirschi JC (2011) Evaluation of a new fine coal cleaning circuit consisting of a stack sizer and a Falcon Enhanced Gravity Concentrator. Int J Coal Prep Util 31:78–95

Ibrahim SS, El Anadoly BE, Farahat MM, Selim AQ, El-Menshawy AH (2014) Separation of pyritic sulfur from egyptian coal using Falcon concentrator. Part Sci Technol 32:588–594

Tao Y-J, Luo Z-F, Zhao Y-M, Tao D (2006) Experimental research on desulfurization of fine coal using an enhanced centrifugal gravity separator. J China Univ Min Technol 16(4):399–403

Honaker RQ, Wang D, Ho K (1996) Application of the Falcon concentrator for fine coal cleaning. Miner Eng 9(11):1143–1156

Honaker RQ, Singh N, Govindarajan B (2000) Application of dense-medium in an enhanced gravity separator for fine coal cleaning. Miner Eng 13(4):415–427

Laplante AR, Buonvino M, Veltmeyer A, Robitaille J, Naud G (1994) A study of the Falcon concentrator. Can Metall Q 33(4):279–288

Honaker RQ, Paul BC, Wang D, Huang M (1995) Application of centrifugal washing for fine coal cleaning. Miner Metall Process 12(2):80–84

Singh RK, Sahu KK, Chalavadi G, Singh R, Padmanabhan NPH Separation characteristics of centrifugal fluidized separator using binary density system. Min Proc Ext Met (TIMM). https://doi.org/10.1080/25726641.2019.1602394

Kroll-Rabotin J-S, Bourgeois F, Climent E (2010) Fluid dynamics based modelling of the Falcon concentrator for ultrafine particle beneficiation. Min Eng 23:313–320

Kroll-Rabotin J-S, Bourgeois F, Climent E (2013) Physical analysis and modeling of the Falcon concentrator for beneficiation of ultrafine particles. Int J Miner Process 121:39–50

Zhu X-N, Tao Y-J, Zhang L (2018) Numerical simulation of flow field in enhanced gravity concentrator. Phys Prob Min Proc. https://doi.org/10.5277/ppmp1899

Hinze JO, Milborn H (1950) Atomization of liquids by means of a rotating cup. J Appl Mech 17(2):145–153

Bruin S (1969) Veocity distribution in liquid film flowing over rotating conical surface. Chem Eng Sci 24:1647–1654

Wagenaar BM, Prins W, Van Swaaij WPM (1994) Pyrolysis of biomass in the rotating cone reactor: modelling and experimental justification. Chem Eng Sci 49(24B):5109–5126

Wagenaar BM, Kuipers JAM, Van Swaaij WPM (1994) Particles dynamics and gas-phase hydrodynamics in a rotating cone reactor. Chem Eng Sci 49(7):927–936

Janse AMC, Dijk PE, Kuipers JAM (2000) The volume of fluid methods in spherical coordinates. Int J Numer Method Heat Fluid Flow 10(7):654–674

Dijk PE, Janse AMC, Kuipers JAM, Van Swaaij WPM (2001) Hydrodynamics of liquid flow in rotating cone. Int J Numer Method Heat Fluid Flow 11(5):386–412

Makarytchev SV, Xue E, Langrish TAG, Prince RGH (1997) On modelling fluid flow over a rotating conical surface. Chem Eng Sci 52(6):1055–1057

Acknowledgements

The authors acknowledge the help and cooperation of the staff of the Mineral Processing Division at CSIR-NML Jamshedpur, India towards the research work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Singh, R.K., Kishore, R., Sahu, K.K. et al. Estimation of the Fluid Velocity Profile in the Stratification Zone of a Falcon Concentrator. Mining, Metallurgy & Exploration 37, 321–331 (2020). https://doi.org/10.1007/s42461-019-00133-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-019-00133-4