Abstract

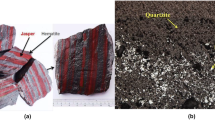

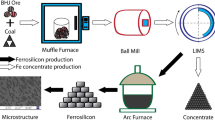

This study investigates upgrading of low-grade banded hematite quartzite iron ore (Fe ~31%). Conventional beneficiation was found to be futile. The susceptibility of iron phases to microwave exposure and their selective absorption assists in the liberation of iron values. Microwave exposure of coarse particles at 540 W for 10 min yielded a concentrate with Fe 56.30% and recovery of 50.68%. Conventional carbothermic reduction at 500 °C, 60 min and 9% charcoal yielded a concentrate with Fe 57.6% and iron recovery of 68%. The presence of sufficiently bonded silica leads to an easy formation of a fayalite phase. The microwave reduction design yielded FeG of 57.6%, FeR of 47% and a yield of 24% at an optimal condition of 540 W, 8 min and 6% charcoal. It was found that a small fraction of microwave-irradiated ore-charcoal mixture melted rapidly, and pure ferrite balls were observed within 8 min. An optical micrograph of a ferrite ball reveals the retained austenite and martensite phase.

Similar content being viewed by others

References

IBM, Indian Minerals Yearbook 2017 (Part III: Mineral Reviews) 56th edition: IRON ORE

Rath SS, Sahoo H, Das SK, Das B, Mishra BK (2014) Influence of band thickness of banded hematite quartzite (BHQ) ore in flotation. Int J Miner Process 130:48–55

Rath SS, Rao D, Dhawan N, Das B, Mishra BK (2014) Optimal recovery of iron values from a low-grade iron ore using reduction roasting and magnetic separation. Sep Sci Technol 49(12):1927–1936

Sahoo H, Kar B, Rath SS, Rao DS, Das B (2014) Processing of banded magnetite quartzite (BMQ) ore using flotation techniques. Powder Technol 256:285–292

Rath SS, Dhawan N, Rao DS, Das B, Mishra BK (2016) Beneficiation studies of a difficult to treat iron ore using conventional and microwave roasting. Powder Technol 301:1016–1024

Ponomar VP, Dudchenko NO, Brik AB (2017) Reduction roasting of hematite to magnetite using carbohydrates. Int J Miner Process 164:21–25

Das B, Mishra BK, Prakash S, Das SK, Reddy PSR, Angadi SI (2010) Magnetic and flotation studies of banded hematite quartzite (BHQ) ore for the production of pellet grade concentrate. Int J Miner Metall Mater 17(6):675–682

Sahoo H, Rath SS, Rao DS, Mishra BK, Das B (2016) Role of silica and alumina content in the flotation of iron ores. Int J Miner Process 148:83–91

Walkiewicz JW, Clark AE, McGill SL (1991) Microwave-assisted grinding. IEEE Trans Ind Appl 27(2):239–243

Tavares LM, King RP (1999) Evaluation of thermally-assisted fracture of particles using micro scale fracture measurements. Kona Powder Part J 17:163–172

Standish N, Huang W (1991) Microwave application in Carbothermic reduction of Iron ores. ISIJ Int 31(3):241–245

Kingman SW, Roason NA (2000) The effect of microwave radiation on the magnetic properties of minerals. J Microw Electromagn Energy 35:144–150

Ishizaki K, Nagata K (2008) Microwave induced solid–solid reactions between Fe3O4 and carbon black powders. ISIJ Int 48(9):1159–1164

Pickles CA (2009) Microwaves in extractive metallurgy: part 2–a review of applications. Miner Eng 22(13):1112–1118

Barani K, Koleini SJ, Rezaei B (2011) Magnetic properties of an iron ore sample after microwave heating. Sep Purif Technol 76(3):331–336

Omran M, Fabritius T, Elmahdy AM, Abdel-Khalek NA, El-Aref M, Elmanawi AEH (2014) Effect of microwave pre-treatment on the magnetic properties of iron ore and its implications on magnetic separation. Sep Purif Technol 136:223–232

Hartlieb P, Toifl M, Kuchar F, Meisels R, Antretter R (2016) Thermo-physical properties of selected hard rocks and their relation to microwave-assisted comminution. Miner Eng 91:34–41

Hayashi M, Takeda K, Kashimura K, Watanabe T, Nagata K (2013) Carbothermic reduction of hematite powders by microwave heating. ISIJ Int 53(7):1125–1130

Yu J, Han Y, Li Y, Gao P (2017) Beneficiation of an iron ore fine by magnetization roasting and magnetic separation. Int J Miner Process 168:102–108

Han H, Duan D, Yuan P, Chen S (2015) Recovery of metallic iron from high phosphorus oolitic hematite by carbothermic reduction and magnetic separation. Ironmak Steelmak 42(7):542–547

Hu M, Wei R, Hu M, Wen L, Ying F (2018) Non-isothermal Carbothermal reduction kinetics of titanium-bearing blast furnace slag. JOM J Miner Met Mater Soc 70(8):1443–1448

Fruehan RJ (1977) The rate of reduction of iron oxides by carbon. Metall Trans B 8:279–286

Crangle J, Goodman GM (1971) The magnetization of pure iron and nickel. Proc R Soc London A 321:477–491

Acknowledgements

The authors would like to thank and acknowledge the funding agency of the Science Engineering Research Board for providing Early Career Research funds. The authors also wish to thank Ms. Kay Argyle for proofreading of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rayapudi, V., Dhawan, N. Processing of Banded Hematite Quartzite Ore for Recovery of Iron Values. Mining, Metallurgy & Exploration 37, 507–517 (2020). https://doi.org/10.1007/s42461-019-00117-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-019-00117-4