Abstract

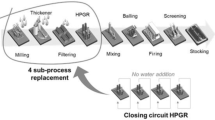

Nowadays, the HPGR (high-pressure grinding rolls) is an intermediate step between filtering and balling in the most modern iron ore pelletizing operation. The operation debottlenecks filtering process and reduces pressure over the typical milling process to control particle size to the balling. The present study evaluated aspects of microwave application to the iron ore concentrate fed to HPGR in a bench scale unit. Iron ore concentrate was irradiated varying the microwave exposure time and grinding efficiency was evaluated. The moisture influence in the HPGR efficiency was also assessed. The pellet feed blaine surface area (BSA) improved by 300 cm2/g and % < 325# fraction by 3%. Scanning electron microscope (SEM) images show the formation of micro-cracks onto the particle surface induced by microwave; the effect observed helped improve the milling process performance, in addition to the moisture reduction observed due to the temperature increase.

Similar content being viewed by others

References

Sportel H, Droog J (1997) Influence of pore saturation on compressive strength of green iron-ore pellets. Ironmaking Steelmaking 24(3):221–223

Kawatra S, Ripke S (2001) Developing and understanding the bentonite fiber bonding mechanism. Miner Eng 14(6):647–659. https://doi.org/10.1016/s0892-6875(01)00056-5

Nunes SF, Viera CB, Goulart LC, Fonseca MC (2014) Influência da Carga Circulante do Pelotamento na Qualidade Física das Pelotas, 2o Simpósio Brasileiro de Aglomeração de Minério de Ferro. Belo Horizonte, MG, Brasil

Forsmo S, Apelqvist A, Björkman B, Samskog P (2006) Binding mechanisms in wet iron ore green pellets with a bentonite binder. Powder Technol 169(3):147–158. https://doi.org/10.1016/j.powtec.2006.08.008

Kapur P, Runkana V (2003) Balling and granulation kinetics revisited. Int J Miner Process 72(1–4):417–427. https://doi.org/10.1016/s0301-7516(03)00116-9

Forsmo Spe, Samskog P-O, Björkman Bmt (2008) A study on plasticity and compression strength in wet iron ore green pellets related to real process variations in raw material fineness. Powder Technol 181(3):321–330. https://doi.org/10.1016/j.powtec.2007.05.023

Leonel CML, Peres AEC (2013) Calcination as additional unit operation in the pelletizing of iron ores presenting high contents of loss on ignition. Ingeniería. Universidad de Atacama 29:1–12

Meer FP (2015) Pellet feed grinding by HPGR. Miner Eng 73:21–30. https://doi.org/10.1016/j.mineng.2014.12.018

Abouzeid AM, Fuerstenau DW (2009) Grinding of mineral mixtures in high-pressure grinding rolls. Int J Miner Process 93(1):59–65. https://doi.org/10.1016/j.minpro.2009.05.008

Ribeiro FS, Russo JF, Costa T (2010) Aplicação de prensas de rolos em minério de ferro. Rem: Revista Escola De Minas 63(2):399–404. https://doi.org/10.1590/s0370-44672010000200027

Zhu D, Pan J, Qiu G, Clout J, Wang C, Guo Y, Hu C (2004) Mechano-chemical activation of magnetite concentrate for improving its pelletability by high pressure roll grinding. ISIJ Int 44(2):310–315. https://doi.org/10.2355/isijinternational.44.310

Barrios G Kp, Tavares LM (2016) A preliminary model of high pressure roll grinding using the discrete element method and multi-body dynamics coupling. Int J Miner Process 156:32–42. https://doi.org/10.1016/j.minpro.2016.06.009

Abazarpoor A, Halali M, Hejazi R, Saghaeian M (2017) HPGR effect on the particle size and shape of iron ore pellet feed using response surface methodology. Mineral Processing Extractive Metallurgy 127(1):40–48. https://doi.org/10.1080/03719553.2017.1284414

Saramak D, Kleiv RA (2013) The effect of feed moisture on the comminution efficiency of HPGR circuits. Miner Eng 43-44:105–111. https://doi.org/10.1016/j.mineng.2012.09.014

Kingman S, Rowson N (1998) Microwave treatment of minerals-a review. Miner Eng 11(11):1081–1087. https://doi.org/10.1016/s0892-6875(98)00094-6

Kumar P, Sahoo B, De S, Kar D, Chakraborty S, Meikap B (2010) Iron ore grindability improvement by microwave pre-treatment. J Ind Eng Chem 16(5):805–812. https://doi.org/10.1016/j.jiec.2010.05.008

Rizmanoski V (2011) The effect of microwave pretreatment on impact breakage of copper ore. Miner Eng 24(14):1609–1618. https://doi.org/10.1016/j.mineng.2011.08.017

Ali A, Bradshaw S (2011) Confined particle bed breakage of microwave treated and untreated ores. Miner Eng 24(14):1625–1630. https://doi.org/10.1016/j.mineng.2011.08.020

Kingman S, Jackson K, Bradshaw S, Rowson N, Greenwood R (2004) An investigation into the influence of microwave treatment on mineral ore comminution. Powder Technol 146(3):176–184. https://doi.org/10.1016/j.powtec.2004.08.006

He CL, Ma SJ, Su XJ, Mo QH, Yang JL (2015) Comparison of the microwave absorption characteristics of hematite, magnetite and pyrite. J Microw Power Electromagn Energy 49(3):131–146. https://doi.org/10.1080/08327823.2015.11689903

Haque KE (1999) Microwave energy for mineral treatment processes—a brief review. Int J Miner Process 57(1):1–24. https://doi.org/10.1016/s0301-7516(99)00009-5

Shaoxian Song AB, Campos-Toro EF, Valdivieso AL (2013) Formation of micro-fractures on an oolitic iron ore under microwave treatment and its effect on selective fragmentation. Powder Technol 243:155–160

Alves, Vladmir Kronemberger, 2015, Claudio Luiz Schneider, Thaís Brasil Duque, Douglas B. Mazzinghy, and Antônio E.C. Peres. Sample requirements for HPGR testing procedure.. Miner Eng 73: 31–38. doi:https://doi.org/10.1016/j.mineng.2014.12.007

Sahoo BK, De S, Carsky M, Meikap BC (2010) Enhancement of rheological behavior of Indian high ash coal−water suspension by using microwave pretreatment. Ind Eng Chem Res 49(6):3015–3021. https://doi.org/10.1021/ie901770d

Athayde M, Cota M, Covcevich M (2018) Iron ore pellet drying assisted by microwave: a kinetic evaluation. Miner Process Extr Metall Rev 39:1–10. https://doi.org/10.1080/08827508.2017.1423295

Charikinya E, Bradshaw S, Becker M (2015) Characterising and quantifying microwave induced damage in coarse sphalerite ore particles. Miner Eng 82:14–24. https://doi.org/10.1016/j.mineng.2015.07.020

Abouzeid AM, Fuerstenau DW (2009) Grinding of mineral mixtures in high-pressure grinding rolls. Int J Miner Process 93(1):59–65. https://doi.org/10.1016/j.minpro.2009.05.008

Acknowledgments

The authors would like to thank Samarco Mining, CAPES-PROEX, CNPq, and FAPEMIG for stimulating and supporting research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Athayde, M., Bagatini, M.C. Iron Ore Concentrate Particle Size Controlling Through Application of Microwave at the HPGR Feed. Mining, Metallurgy & Exploration 36, 353–362 (2019). https://doi.org/10.1007/s42461-018-0013-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-018-0013-y