Abstract

Carbon dioxide (CO2) injection is an enhanced oil recovery technique used worldwide to increase oil recovery from hydrocarbon reservoirs. Immiscible CO2 injection involves injecting the CO2 into the reservoir at a pressure below which it will become miscible in the oil. Even though immiscible CO2 injection has been applied extensively, very little research has been conducted to provide a comprehensive understanding of the mechanism and the applications of immiscible CO2 injection. This research performs an in-depth data analysis is performed based on more than 200 experiments and 20 field tests from more than 40 researches to show the conditions at which immiscible CO2 injection has been applied and the most frequent application conditions. Histograms and boxplots have been generated for temperature, CO2 injection pressure, oil viscosity, molecular weight, and API gravity, CO2 solubility, and finally oil swelling to show the ranges and frequency of application for all these parameters. Finally, crossplots have been generated from the data to show the relation of pressure and temperature to CO2 solubility and oil swelling. The crossplots function to illustrate a relation between the variables and draws a conclusion as to what effect each parameter will have on the other.

Similar content being viewed by others

1 Introduction

One of the most widely applied, and highly advantageous and productive enhanced oil recovery (EOR) methods is carbon dioxide injection. CO2 can be injected into the reservoir as a miscible solvent, or an immiscible fluid [1,2,3]. The choice of whether the CO2 should be miscible or immiscible is based on many factors mainly the reservoir fluid properties, including oil viscosity, molecular weight (MW), API gravity, and composition, and reservoir rock properties, including pay zone depth, thickness, and mineralogy. Generally, when miscibility is difficult to achieve, as is the case in moderately to heavily viscous oils, immiscible CO2 becomes extremely valuable [4].

When the immiscible CO2 is injected into the reservoir, one of the most significant interactions that occur between the gas and the oil is manifested in CO2 solubility. During solubility, the CO2 will diffuse into the oil and thus the oil will begin to swell [5,6,7]. Different crude oils will have different solubility based on their composition and properties, such as API gravity and Molecular Weight (MW) [8, 9]. Another important parameter that has been shown to impact CO2 solubility in crude oil is the thermodynamic conditions of the reservoir. Increasing the CO2 injection pressure will result in a higher solubility, whereas increasing the temperature will result in a decrease in solubility due to the CO2 molecules having a much higher activity of the CO2 molecules at higher temperatures [10, 11]. Solubility will occur in both miscible and immiscible solvent injection, with the main difference being that during miscible injection, the interfacial tension between the oil and the CO2 will become zero [12, 13]. Due to the high solubility of CO2 in crude oil during immiscible CO2 injection, this application can have a strong influence on increasing oil recovery, even from heavy oil reservoirs [14, 15]. Even though solubility has been proven to be an extremely important factor during immiscible CO2 injection, no comprehensive data analysis has yet been performed to determine its overall impact on different crude oil from lab and field studies.

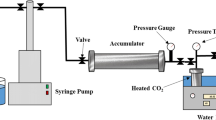

CO2 solubility will result in the oil increasing in size, or swelling. This swelling will help the crude oil acquire several beneficial characteristics, such as a lower viscosity, a higher relative permeability, and a larger volume. In order to measure the extent to which the crude oil has swollen, several experimental methods have been investigated. Most of the experiments conducted to evaluate oil swelling depended on transparent visualization experiments that can permit the ability to see the swelling phenomenon. Of these setups, the flow visualization experiments, and the pendant drop methods are the most widely utilized [6, 16, 17]. Core flooding experiments have also been conducted to study the ability of immiscible CO2 to increase oil recovery [18]. Immiscible CO2 injection has also been coupled with other injection fluids such as water, and steam in hopes of increasing oil recovery [19,20,21]. Due to the abundance of methods by which oil swelling can be measured, and the many ways by which immiscible CO2 injection can be applied, it is important to provide a guideline to these methods and their advantages and limitations.

Several mathematical and simulation modellings have also been used to study immiscible CO2 injection. Several empirical correlation have been developed along the year to predict CO2 solubility in crude oil and oil swelling [22,23,24]. CO2-Oil interaction using reservoir simulation and computer modelling have been studied using basic black oil reservoir models, and also complex models that can distinguish the different phases and the interfacial tension [25,26,27]. Recently, a more complex computer modelling technique referred to as Gene Expression Programming was used to develop a novel correlation used to determine CO2 swelling in oil as a function of oil MW, oil specific gravity, reservoir temperature, bubble point pressure, and saturation pressure [28].

A plethora of researches and studies have been conducted using immiscible CO2 injection in reservoirs and cores with light and intermediate crude oil. Immiscible CO2 injection has been shown to be successful in producing from reservoirs with heavy oil as well. It is unclear at what conditions is immiscible CO2 injection best applied. In order to be able to accurately and successfully apply immiscible CO2 injection in both lab experiments and field studies, it is important to have a comprehensive understanding of the CO2-oil interactions, and the extent to which they can alter different crude oil properties and characteristics. This research performs a data analysis based on more than 200 experiments and 20 field tests from more than 40 researches to show the conditions at which immiscible CO2 injection has been applied and the most frequent application conditions. This will help determine the applicability range of immiscible CO2 and improve on its application by illustrating where it can be applied most effectively.

2 Immiscible CO2 injection data analysis

The data analysis was performed on more than fifty researches and field studies done on immiscible CO2 injection in order to determine the ranges at which immiscible CO2 injection was applied, and the most frequent application conditions. The data collected was from laboratory experiments, field tests, simulation models, review papers, and empirical researches using mathematical models. The percentage of data collected from each type of study is summarized in Fig. 1. Almost half of the data was collected from experimental results, followed by simulation results which represented almost third of the data collected, and then finally the field, empirical and review data which represented close to a third of the data as well.

2.1 Data processing methods

2.1.1 Histograms

Histograms, also known as frequency plots, are usually depicted as column plots that represent different ranges of a variable and the frequency at which each range has been observed. Histograms are extremely important statistical analysis tools since they can easily show the most frequent range of application of a specific parameter or factor and thus determine the best applicability range based on previous studies and tests. Histograms are therefore essential when developing a new screening criteria for a specific application. The histograms developed in this research include Pressure and Temperature, Oil properties including oil MW, viscosity, and API Gravity, and finally the CO2 impact on oil, which includes the CO2 solubility, and oil swelling as a result of CO2 interaction with the oil. An illustration of a typical histogram can be shown in Fig. 2.

2.1.2 Boxplots

Boxplots are important statistical analysis tools that can reveal much information about the data available. The boxplots can be used to determine how well the data is distributed. A common boxplot, such as the ones generated in this study, can be divided into five main components. The top part of the boxplot represents the maximum value found in all of the data points, whereas the bottom part represents the minimum value. The top box represents the third quartile range (75th percentile), while the bottom box represents the first quartile range (25th percentile). The middle line represents the median value, or the second quartile range (50th percentile). The cross mark points out the mean value of the data points. Boxplots for the CO2 injection pressure, porous media temperature, oil properties, and CO2 solubility and oil swelling have been generated in this research. Figure 3 shows an illustration of a boxplot and all the important sections within it.

2.1.3 Crossplots

Crossplots are plots that relate one parameter to the other or attempts to illustrate or determine a relation between two, or more, parameters. A general trend can be observed in a crossplot, and sometimes a relation or mathematical model can be generated if enough data is utilized. This research generates four crossplots in an attempt to relate oil swelling and carbon dioxide solubility to both pressure and temperature.

2.2 Methodology

After the data was collected, a data set was created and then the data was processed by converting the units for all the values, determining and removing outliers, and plotting histograms, boxplots, and crossplots to reveal several relations between the variables. Table 1 summarizes all the histograms, and boxplots that were generated, and the units used for each studied factor.

Four crossplots were also generated using the data; these include pressure and temperature vs both CO2 solubility and oil swelling respectively. The histograms, boxplots, and crossplots will all be presented in this research and the significance of each plot will be explained.

3 Results and analysis

3.1 Pressure and temperature histograms

The CO2 injection pressure and the reservoir temperature are two extremely important factors that will impact the CO2 dissolution in the oil, and also the oil swelling, and thus will impact the productivity of the immiscible CO2 injection process. As the reservoir temperature increases, the CO2 solubility in the oil will decrease due to the increase in the activity of the gas molecules which will result in a tendency of the molecules to liberate from solution rather than become soluble in the oil [29, 30]. This decrease in solubility will result in a lower oil swelling, which in turn will result in a decrease in oil recovery due to the decrease in the interaction of the CO2 with the oil. Increasing the CO2 injection pressure on the other hand will result in an increase in the CO2 solubility, and thus an increase in the CO2 interaction with the oil. This is due to the gas molecules being compressed into a smaller volume and thus will tend to solubilize in the oil. Increasing the pressure to an extremely high value will eventually result in the CO2 becoming miscible in the oil [31, 32]. Therefore, for immiscible CO2 injection, a lower reservoir temperature, and a higher CO2 injection pressure is more favorable, as long as the pressure remains beneath the miscibility pressure, and the formation fracture pressure.

The histograms for both the temperature and the pressure are shown in Fig. 4. The highest frequency range is depicted in orange, the second highest is depicted in yellow, and the lowest frequency range is depicted in blue. The highest frequency range for the temperature histogram was between 20–30 °C, which is due to the higher CO2 solubility at lower temperatures, as was explained before. The second highest was between 41–50 °C which is considered a medium temperature range; this range has a high frequency since CO2 is usually preferred in its supercritical phase due to its advantageous properties at this phase. Supercritical CO2 occurs at approximately 31.4 °C, and 1071 psi and thus this temperature range also had a high frequency. The highest frequency range of pressures occurred at pressures ranging from 10 to 500 psi and pressures between 501 and 1100 psi. The majority of the values were near the 500 psi and 1100 psi, with most of the data coming from experimental results. The lower pressure ranges were tested more frequently due to most of the experiments testing immiscible CO2 injection, and thus most of the researches tried to prevent the CO2 from being miscible or partially miscible and thus lower pressures were preferred. The researches that used high pressures used crude oil with extremely high viscosity and thus miscibility was extremely difficult to reach. The range between 500 and 1100 psi was also very frequent, with most of the values in this range being close to the 1100 psi to ensure the CO2 was in the supercritical state.

3.2 Oil properties histograms

Histograms for three oil properties were generated in this research, including oil MW, oil viscosity, and oil API gravity. Figure 5 shows the histograms for both the oil MW and the oil viscosity. The highest oil MW frequency was found to be the oil MW above 500 g/mol. This is mainly due to the immiscible CO2 injection becoming a common research direction and field implementation in heavy oil reservoirs due to its potential to increase oil recovery, and its lower cost and higher applications compared to thermal methods such as steam injection [33,34,35]. The highest frequency oil viscosity range was found to be between 100–500 cp, which complements the results for the oil MW since in this range the oil is classified as heavy oil, based on the definition of heavy oil provided by Gao et al. [15] who defined heavy oil as having a viscosity greater than 100 cp.

The histogram showing the oil API gravity is represented in Fig. 6. The highest frequency oil API gravity was in the range between 10.1–20°API, while the second highest frequency was between 30.1–40°API, both of which fall under the classification of heavy oil, above 10°API [15]. These results indicate that immiscible CO2 injection has a high potential to produce from heavy oil reservoirs.

3.3 Solubility and swelling histograms

The interaction of CO2 with the crude oil was also studied in this data analysis by generating histograms for both CO2 solubility, and oil swelling, shown in Fig. 7. The highest frequency for the CO2 solubility was found to be the 0–0.1 mol/mol, while the highest frequency for the oil swelling was 1–1.1 ml/ml, both of which were the lowest ranges in the histograms. This can be explained through the CO2 injection pressure histogram in Fig. 4, where most of the application for immiscible CO2 injections were found at the lowest pressure range, and since both CO2 solubility and oil swelling are a strong function of injection pressure, the lowest ranges for both were found to be the ones with the highest frequency. This could be due to the researches being focused on immiscible CO2 injection and thus lower pressure ranges were used to avoid CO2 miscibility, since an increase in pressure may lead, at some point, to the CO2 becoming miscible in the oil, especially if the oil viscosity is low as was used in many of the researches analyzed, based on the results presented in Fig. 5.

3.4 Pressure and temperature boxplots

The boxplots for both the CO2 injection pressure and the temperature are shown in Fig. 8. The maximum pressure used was 5000 psi, which is considered extremely high. This pressure was used for bitumen since, even at this high of a pressure, the CO2 was not miscible. The lowest pressure used was close to 10 psig, equivalent to 24.7 psi. The highest temperature used was 315 °C, whereas the lowest used was 16 °C. For both boxplots, the distribution of the data in the first quartile range was much better than in the third quartile range, which is evident from the size of the rectangles within the boxplot. The median value was closer to the first quartile range which signifies than the majority of the data was closer to the lower values, which was the same conclusion observed from the histograms in Fig. 4.

3.5 Oil properties boxplots

The boxplots for the oil MW and viscosity are shown in Fig. 9. The boxplot for the oil MW shows no maximum value bar since the maximum value was integrated within the third quartile range due to the distribution of the data being extremely well. The minimum MW observed was 80 g/mol. The median value is much closer to the third quartile range since the majority of the data points were within this range, which is evident from the histogram shown in Fig. 5. The oil viscosity boxplot shows an opposite trend with the median and the first quartile range being almost unnoticeable. This is due to the maximum frequency being extremely close to the median, with the majority of the data points closer to the first quartile range. The maximum viscosity observed was 23,000 cp, which was for the bitumen.

Figure 10 shows the boxplot for the oil API gravity. The maximum value recorded was close to 80°API, which signifies a very light oil, while the minimum was 3°API. The median value is closer to the first quartile range due to the highest frequency of data being close to that range, as was shown in the histogram in Fig. 5.

3.6 Solubility and oil swelling boxplots

The solubility and oil swelling boxplots are shown in Fig. 11. The CO2 solubility shows an almost symmetrical boxplot, which may signify that the data points are very closely distributed. This can be clearly seen in the CO2 solubility histogram in Fig. 7 where most of the peaks are extremely close in value. The highest solubility recorded was close to 1, which signifies that most of the CO2 was soluble in the oil; this is a strong indication that miscibility was almost achieved at that point. The oil swelling boxplot shows a maximum swelling of 2.2, which is considered an extremely high value, and a minimum swelling of 1, which indicates no swelling. The median value is closer to the first quartile range since this is where the maximum frequency was observed in the histogram, Fig. 7.

3.7 Crossplots

Four crossplots were generated in this research to study the impact of CO2 injection pressure and porous media temperature on CO2 solubility and oil swelling. Figure 12 shows the effect of pressure and temperature on CO2 solubility. The blue data points were found to be outliers. For the CO2 solubility versus pressure plot, the data points show a trend of increasing solubility with pressure. This shows that as the CO2 injection pressure increases, the solubility of the CO2 in the oil will also increase, which is the same conclusion reached by most researchers. The plot showing CO2 solubility versus temperature shows no obvious trend, however, at the highest temperatures, almost all the data points show a very low CO2 solubility, which is what most researchers also observed as the temperature increased. For example, at 150, and 190 °C, all of the data points show a solubility of less than 0.05 mol/mol.

The effect of pressure and temperature on oil swelling is shown in Fig. 13. The blue data points represent outliers. As was stated earlier, as the CO2 injection pressure increases, the oil swelling will increase as well. This is the same trend that can be observed in the plot showing oil swelling versus pressures. Regarding oil swelling versus temperature, the general trend shows a decrease in oil swelling with the increase in temperature, which is identical to what was explained previously.

4 Conclusions

This research performs a data analysis based on hundreds of experimental, simulation, and field data to generate multiple histograms, boxplots, and crossplots in order to determine the data distribution and most frequent data range found for immiscible CO2 injection. The main findings from this research are summarized as follows:

-

Oil swelling is one of the main mechanisms that occurs during immiscible CO2 injection, and is dependent on CO2 solubility. Many factors will impact oil swelling including reservoir thermodynamic, rock, and fluid properties.

-

Based on the data analysis performed, most of the data shows that lower pressures and low temperatures were used during immiscible CO2 injection. This was to avoid miscibility of CO2 since the main focus was immiscible CO2.

-

Based on the oil properties data analysis, immiscible CO2 has been used to produce from heavy oil, since the histograms showed the highest frequencies in the heavy oil zone.

-

Crossplots generated showed that CO2 solubility, and oil swelling are highly dependent on the CO2 injection pressure, and the reservoir temperature.

Abbreviations

- Fs :

-

Oil swelling factor

- Vso :

-

Volume of swelled oil

- Vuo :

-

Volume of unswelled oil

- δ:

-

Binary interaction parameter

- T:

-

Temperature

- Tc :

-

Critical Temperature

- ω:

-

Acentric factor

- Rs :

-

Solution gas

- Ps :

-

Saturation Pressure

- γ:

-

Specific Gravity

- SCO2 :

-

CO2 solubility

- MW:

-

Molecular weight

References

Martin D, Taber J (1992) Carbon dioxide flooding. J Pet Technol 44:396–400. https://doi.org/10.2118/23564-PA

Shokoya O et al (2002) Evaluation of the miscibility and contribution of flue gas to oil recovery under high pressure air injection. J Can Pet Technol. https://doi.org/10.2118/02-10-03

Yongmao, H. et al. (2004) Laboratory investigation of CO2 flooding. Society of Petroleum Engineers. https://doi.org/10.2118/88883-MS

Klins MA, Ali SMF (1982) Heavy oil production by carbon dioxide injection. J Can Pet Technol. https://doi.org/10.2118/82-05-06

Yang C, Gu Y (2006) Diffusion coefficients and oil swelling factors of carbon dioxide, methane, ethane, propane, and their mixtures in heavy oil. Fluid Phase Equilib J 243:64–73

Yang C, Gu Y (2007) A novel experimental technique for studying solvent mass transfer and oil-swelling effect in the vapour extraction (VAPEX) process. Petroleum Society of Canada. https://doi.org/10.2118/07-09-04

Yang C, Gu Y (2004) Visualization of interfacial interactions of crude oil-CO2 systems under reservoir conditions. Society of Petroleum Engineers. https://doi.org/10.2118/89366-MS

Silva MK, Orr FM Jr (1987) Effect of oil composition on minimum miscibility pressure-part 1: solubility of hydrocarbons in dense CO2. SPE Reserv Eng 2:468–478. https://doi.org/10.2118/14149-PA

Henni A, Mather AE (1999) Solubility of CO, NO, CH, and CH in polar solvents. J Can Pet Technol. https://doi.org/10.2118/99-13-25

Svrcek WY, Mehrotra AK (1982) Gas solubility, viscosity and density measurements for Athabasca bitumen. J Can Pet Technol. https://doi.org/10.2118/82-04-02

Svrcek WY, Mehrotra AK (1989) Properties of peace river bitumen saturated with field gas mixtures. J Can Pet Technol. https://doi.org/10.2118/89-02-01

Holm L, Josendal VA (1974) Mechanisms of oil displacement by carbon dioxide. J Can Pet Technol 26:1–427. https://doi.org/10.2118/4736-PA

Vali J et al (2011) A fast and simple method for modeling of oil swelling in CO2 injection. Geopersia 1:39–46

DeRuiter RA et al (1994) Solubility and displacement behavior of a viscous crude with CO2 and hydrocarbon gases. SPE Reserv Eng 9:101–106. https://doi.org/10.2118/20523-PA

Gao C et al (2013) Heavy oil production by carbon dioxide injection. Greenh Gases Sci Technol J 3:185–195

Bahralolom IM, Orr FM Jr (1988) Solubility and extraction in multiple-contact miscible displacements: comparison of N2 and CO2 flow visualization experiments. SPE Reserv Eng 3:213–219. https://doi.org/10.2118/15079-PA

Sugai Y et al (2014) Consideration of an Effect of Interfacial Area between Oil and CO2 on Oil Swelling. J Pet Explor Prod Technol 4:105–112

Sasaki K. et al. (2013) CO2 solubility characteristics of crude oils related to carbon capture and utilization (CCU). In: Novel carbon resource sciences newsletter, pp 1–8

Beeson DM, Ortloff GD (1959) Laboratory investigation of the water-driven carbon dioxide process for oil recovery. J Pet Technol 11:63–66. https://doi.org/10.2118/1100-G

Zhang YP et al. (2006) Laboratory investigation of enhanced light-oil recovery by CO2/flue gas huff-n-puff process. Petroleum Society of Canada. https://doi.org/10.2118/06-02-01

Al-Murayri MT et al (2011) Solubility of methane, nitrogen, and carbon dioxide in bitumen and water for SAGD modelling. J Can Pet Technol 50:34–45. https://doi.org/10.2118/148630-PA

Mullken CA, Sandler SI (1980) The prediction of CO2 solubility and swelling factors for enhanced oil recovery. Ind Eng Chem Process Des Dev 19:709–711

Pacheco-Roman FJ, Hejazi SH (2015) Estimation of solubility and diffusivity of gases in heavy oils by use of late-time pressure-decay data: an analytical/graphical approach. SPE J 20:717–728. https://doi.org/10.2118/170957-PA

Barclay TH, Mishra S (2016) New correlations for CO2-oil solubility and viscosity reduction for light oils. J Pet Explor Prod Technol 6:815–823

Hatzignatiou DG, Lu Y (1994) Feasibility study of CO2 immiscible displacement process in heavy oil reservoirs. Petroleum Society of Canada. https://doi.org/10.2118/94-90

Al-Jarba M, Al-anazi BD (2009) A comparison study of the CO2-oil physical properties literature correlations accuracy using visual basic modelling technique. NAFTA J 60:287–291

Honarpour MM et al. (2010) Rock–fluid characterization for miscible CO2 injection: residual oil zone, seminole field, permian basin. Society of Petroleum Engineers. https://doi.org/10.2118/133089-MS

Rostami A et al (2017) Modeling of CO2 solubility in crude oil during carbon dioxide enhanced oil recovery using gene expression programming. Fuel 210:768–782

Norouzi H et al (2018) Analysis of secondary and tertiary high-pressure gas injection at different miscibility conditions: mechanistic study. SPE Reserv Eval Eng 22:150–160. https://doi.org/10.2118/191119-PA

Nourozieh H et al (2016) Measurement and correlation of solubility and physical properties for gas-saturated Athabasca bitumen. SPE Prod Oper 31:207–218. https://doi.org/10.2118/176016-PA

Farias M, Watson R (2007) Interaction of nitrogen/CO2 mixtures with crude oil. Final report to Department of Energy, Pennsylvania State University, Department of Energy and Geo-Environmental Engineering

Yin M (2015) CO2 miscible flooding application and screening criteria. Masters Thesis, Petroleum Engineering Department, Missouri University of Science and Technology

Kang S et al (2013) Scientific research and field application of co immiscible flooding in heavy oil recovery. Society of Petroleum Engineers. https://doi.org/10.2118/165210-MS

Fakher S, Imqam A (2018) Asphaltene precipitation and deposition during CO2 injection in nano shale pore structure and its impact on oil recovery. Fuel 237:1029–1039. https://doi.org/10.1016/j.fuel.2018.10.039

Fakher S, Imqam A (2018) Investigating and mitigating asphaltene precipitation and deposition in low permeability oil reservoirs during carbon dioxide flooding to increase oil recovery. Society of Petroleum Engineers. https://doi.org/10.2118/192558-MS

Acknowledgements

The author Sherif Fakher wishes to thank Missouri University of Science and Technology for its support through the Chancellors Distinguished Fellowship.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fakher, S., Imqam, A. A data analysis of immiscible carbon dioxide injection applications for enhanced oil recovery based on an updated database. SN Appl. Sci. 2, 448 (2020). https://doi.org/10.1007/s42452-020-2242-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-020-2242-1