Abstract

The direct application of poultry litter (PL) in the soil leads to some environmental problems. Poultry litter biochar (PLB) produced through the pyrolysis process under limited oxygen supply at 400 °C for 10 min, and nutrients were analyzed for both PL and PLB. Both PL and PLB were applied in the soil at 1, 2, and 3% (w/w) along with control. Ipomoea aquatica was grown in earthen pots for 60 days to evaluate the response of both PL and PLB. After pyrolysis of PL, the nutrients content (total N, K, S, Ca, Mg, and Zn), pH, electric conductivity, and organic carbon in PLB were found to be increased than those of PL except for P. Plant height significantly increased by 14.3, 23.3, 20.1%; and 17.8, 34.4, 32.4% after the application of 1, 2, and 3% PL and PLB, respectively, as compared to the control. Plant fresh weight significantly increased by 70.4, 124.6, and 124.7% and 53.3, 134.3, and 200.4% compared to the control after the application of PL and PLB at 1, 2, and 3%, respectively. Increased plant height and fresh weight can be ascribed mostly to the capacity of PL and PLB as a source of nutrients for plant uptake. The significantly higher yield was observed at 3% PLB application. Compared to the PL, plant height and fresh weight increased by 18.2 and 33.68%, respectively, at 3% PLB application. PLB rather than PL might be a promising organic amendment for maintaining sustainable agriculture.

Similar content being viewed by others

1 Introduction

The term ‘biochar’ is a relatively recent development, and its global interest as an organic soil fertilizer is rapidly emerging day by day. Biochar is a stable carbon-rich natural product, produced by thermal conversion (pyrolysis) of organic material in an oxygen-limited condition, and it requires relatively low-to-moderate temperatures (< 700 °C) to produce [1, 2]. Recently, biochar has dragged the attention of many researchers because of its unique characteristics that promote sustainable and climate-smart agriculture [3, 4]. The application of biochar into the soil can be considered as a new soil management strategy that helps to improve soil fertility and productivity in conjunction with environmental management and mitigation of climate change. Furthermore, due to its stable nature, it decomposes slowly than the other organic materials which indirectly control carbon emission produced from natural product degradation [1, 4, 5]. Biochar also plays a potential role in the remediation of heavy metals- and toxic pollutants-contaminated soil by acting as an efficient adsorbent [6, 7]. It has a positive influence to improve soil physicochemical properties, soil aggregation, water and nutrient retention, nutrient availability, and microbial activity. Side by side, biochar is an active substance for liming and control nutrient balance in soil [2, 8, 9]. Moreover, its specific chemical structure is resistant to microbial decay and provides nutrients for a long time and consequently promotes plant growth, yield, and quality of crops [10, 11].

Biochar can be produced from different types of organic substances, including agricultural wastes, animal manures, nutshells, wood residues, leaves, rice husks, etc. Some experimental results revealed that biochar produced from animal manure is more nutrient rich than that produced from agricultural waste [2, 4, 11]. Poultry litter (PL) is one of the most common and widely available animal manures, which is obtained from poultry industries. Globally poultry production has been growing at a rate of around 5% per annum [12], and within the last two decades, the growth rate is almost 20% in Bangladesh [13]. Another report revealed that there are about more than 296 million poultry (chicken plus duck) in 2012–2013 in Bangladesh [14]. Poultry litter is a common and hugely generated waste product from poultry industries. According to Waste Concern [15], in Bangladesh, a total of 42 million chickens produce about 3079 metric tons of poultry manure daily. It is estimated that about 0.7–2.0 tons of litter per year were generated from 1000 chickens [16].

Poultry litter has high nutritional values, and thus, it is considered a good source of organic fertilizer [17]. Despite being a potential source of plant nutrients, the mismanagement and improper application of PL lead to different problems including nutrient leaching, soil acidification, over-application of P results in eutrophication, emission of different harmful gases like ammonia which causes nasal irritation, health hazards, and environmental pollution [18,19,20]. On the other hand, another primary concern is that fresh PL is a reservoir of different pathogens. So, surface and subsurface water are easily being contaminated carried with runoff water from croplands [21, 22]. That is why sustainable management system of PL is a crying need to avoid the adverse effects of this valuable organic resource. Among different management strategies of PL, the production of biochar from PL is a new management approach that can be considered as a safer and more effective alternative to utilize this resource in agriculture. Poultry litter biochar (PLB) helps to retain nutrients and provide nutrients for a long time by slow release than that of PL. Besides, the pyrolysis temperature makes it pathogen free. So, using PLB minimizes environmental hazard as well as improves soil fertility and promotes plant growth [2, 11, 23].

In temperate regimes, the higher rate of soil organic matter (SOM) decomposition and mineralization is a fundamental problem of SOM depletion and excessive greenhouse gasses emission [24, 25]. So, here, the application of this stable organic material in agricultural land can be considered as a very prospective strategy for the betterment of soil quality, sustainable crop production, as well as mitigation of the environmental problems. The experimental results on the potentiality of biochar are controversial. Though most of the worldwide researches showed positive results, in some cases, it is negative [11, 26, 27].

In Bangladesh, poultry waste (litter, feather, and others) is not solely used as a fertilizer. A vast percentage of poultry waste is left in the open dump for a significant time before being used as a fertilizer, a portion is used as fish feed, and only a minor portion of waste is composted and used as a replacement for chemical fertilizer. Moreover, there is little research work on biochar production from PL and its uses in agricultural soil in Bangladesh. That is why an experiment was conducted on a short scale by taking the most available organic resource PL as experimental material for biochar production.

Ipomoea aquatica was used as the test plant in this experiment. It is a high yielding and leafy vegetable which is grown widely in Bangladesh. Both leaves and petioles are edible. The petiole of the leaf and stem is green, soft, and fleshy. Usually, a leaf is 6–9 cm long and 5–8 cm wide. The flower is white. The seed coat is hard and grey. Planting season and time is kharif season (February–May) but is cultivated everywhere in Bangladesh with or without irrigation facilities throughout the year. First harvesting starts after 30 days of seed sowing, and subsequent harvest can be done at 10 days interval. It has the capacity to regrowth from its shoots which is helpful to obtain yield throughout the year [28].

The objective of this study was (1) to produce PLB through pyrolysis as a possible means of PL management; (2) to evaluate the chemical properties of PL and its resulting biochar product; and (3) to assess its influence on plant growth as an organic nutrient source after incorporation into agricultural soils at different doses.

2 Materials and methods

The research had two parts. In one part, PLB was produced from PL, and its chemical characterization was performed; in another part, a pot experiment was carried out to evaluate the effect of both PL and PLB on the growth of kangkong (Ipomoea aquatica), a popular leafy vegetable plant in Bangladesh. This plant was selected as an experimental plant because it is cultivated easily everywhere in Bangladesh and very convenient to observe the growth performance under different doses of treatment. The experiment was carried out in the field laboratory of Soil, Water and Environment Discipline, Khulna University, Bangladesh.

2.1 Collection of soil sample and poultry litter

The soil sample was collected from the agricultural field inside the Khulna University campus, Khulna by following the procedure suggested by USDA [29]. Poultry litter was collected from the poultry farm of Mailmara village owned by a village farmer in Khulna district.

2.2 Preparation of soil and poultry litter

The collected soil sample was air-dried by spreading on a plastic sheet. After that, the larger soil aggregates were broken down into small pieces by using a wooden hammer and sieved through a 2.0-mm sieve for using as plant growth medium and 0.5-mm sieve for laboratory analysis of the soil sample. Collected PL was sun-dried and stored for making PLB.

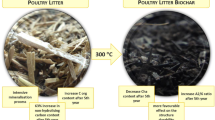

2.3 Production of poultry litter biochar

Poultry litter biochar was created through a pyrolysis process utilizing a muffle furnace (FH-05, WiseTherm, Korea) under restricted oxygen condition [30,31,32]. The pyrolysis conversion was carried out in the soil chemistry laboratory of Soil, Water and Environment Discipline, Khulna University, Bangladesh. The pre-prepared (dried) PL was taken into porcelain cups and put in inside a muffle furnace at 400 °C temperature for 10 min. Thus, the PLB was produced in this trial by a slow pyrolysis method according to the review of Brownsort [33]. At that point, the char materials were crushed utilizing mortar and pestle and sieved through a 0.5-mm strainer.

2.4 Experimental layout

For the pot experiment, twenty-one earthen pots (2-L) were collected, and each pot was filled up with one kg of sieved soil. The surface area of the pot was 214 cm2, and the height was 15 cm. Three different doses (1, 2, and 3%; w/w) of PL and PLB along with control and three replications for each treatment were applied. After proper mixing of PL and PLB into the soil, the pots were kept bare for two weeks and watered well. Fifteen healthy seeds of kangkong were sown in each pot. Thinning was done manually after ten days from seed germination, leaving ten straight and healthy plants in each pot, and other plants were manually removed carefully by uprooting. Irrigation was done with a similar amount of water for each pot very carefully according to the need of the plant to avoid root rot. After 60 days of seed sowing, plants were harvested by cutting the stems about 1 cm above the ground and plant height and fresh weight were measured and recorded by using measuring scale and electric balance, respectively.

2.5 Laboratory analyses

Similar methodologies were used for chemical analyses of soil, PL, and PLB. pH (1:2.5 ratio) and EC (1:5 ratio) were determined with the help of glass electrode pH meter and EC meter (D-54, Horiba, Japan), respectively [34]. Total N was measured by the micro-Kjeldahl method following H2SO4 acid digestion, as suggested by Jackson [34]. Organic carbon was determined by the wet oxidation method using potassium dichromate and sulfuric acid system [35]. Available P was extracted from the samples with 0.5 M NaHCO3 at pH 8.5 [34], and P was determined using a spectrophotometer (T60U, UV–visible spectrophotometer, PG Instruments Ltd) by the ascorbic acid blue color method [36]. The other nutrients, K by using flame photometer (PFP7 Flame Photometer, JENWAY), S by using a spectrophotometer (T60U, UV–visible spectrophotometer, PG Instruments Ltd), Zn, Ca, and Mg by using atomic absorption spectrometer (AA240 FS, Fast Sequential Atomic Absorption Spectrometer, VARIAN, Australia) were measured by following the methods described in Imamul Huq and Alam [37].

2.6 Statistical analyses

Data were analyzed statistically, following the ANOVA technique by using MINITAB 17.0, and the mean differences were adjusted by DMRT. Graphs were also drawn by using MINITAB 17.0.

3 Results and discussion

3.1 Properties of soil, PL and PLB

The chemical properties of the soil, PL, and PLB that were used in this experiment are shown in Table 1. The nutritional values showed that most of the nutrients were increased in PLB after the pyrolysis of PL. Specifically, total N, K, Ca, and Mg were increased markedly. After the pyrolysis of PL, the OC content was increased from 23 to 36%. It represents PLB as a carbon-rich compound and results in an improvement of SOM as well as soil fertility [1]. Our finding was similar to the results of Chan et al. [11]. The total N content (1.6%) of PLB was higher than that of PL (0.5%). A similar result was also reported by Cantrell et al. [38], and the reason behind the increase could be due to the occurrence of recalcitrant N in heterocyclic compounds [39]. However, Chan and Xu [40], reported a different statement that the total N content of PL decreased after pyrolysis. The value of available P was almost similar in both cases. Nevertheless, Cantrell et al. [38] obtained an increased and Cely et al. [41] found a decreased P content after PLB production. Knoepp et al. [42] stated that P starts to volatilize at temperatures of about 770 °C, but in our experiment, the pyrolysis temperature was 400 °C. This temperature variation might be the reason for similar P content in both PL and PLB. Positive results were also observed in the case of other nutrients like K, S, Zn, Ca, and Mg contents after PLB production. Our results were in good accordance with the results of Cantrell et al. [38].

3.2 Effects of PL and PLB on the growth of kangkong

3.2.1 Plant height

Application of different doses of both PL and PLB significantly (p for PL < 0.001 and p for PLB 0.001) increased the average height of kangkong than that of control. The lowest plant height (17.53 ± 0.42 cm) was observed in control, and the highest (26.73 ± 2.25 cm) was under 2% PLB application though plant height under 2% and 3% PLB were statistically similar and significantly higher than others (Table 2). It was found that compared to the control, plant height significantly increased by 14.3, 23.3, and 20.1% after the application of PL at 1, 2, and 3%, respectively, while with the same application rate of PLB the plant height increased significantly by 17.8, 34.4, and 32.4%, respectively. Compared to the PL, plant height increased by 4.2, 16.9, and 18.2% after the application of PLB at 1, 2, and 3%, respectively. Our findings were very similar to other researchers [43, 44]. They stated the positive effects of PLB on plant height than that of PL application. High nutritious values, the addition of OM into the soil, and slow release of nutrients for a long time due to its stability might be the main reasons behind the fruitful response of PLB in plant height [2, 11].

3.2.2 Fresh weight

The changes in fresh weight (g/plant) after the application of PL and PLB at different doses are presented in Table 2. Since PL itself is a good source of plant nutrients, plant fresh weight was increased after both PL and PLB applications under each treatment dose compared to control. Though all the treatments increased the fresh weight as compared to control, the plants grown in 3% PLB application were significantly (p < 0.001) higher than all the treatments. The minimum plant fresh weight was observed in control (5.77 ± 0.31 g/plant) and the maximum (17.33 ± 4.42 g) in 3% PLB application. Plant fresh weight significantly increased by 70.4, 124.6, and 124.7% with compared to the control after the application of PL at 1, 2, and 3%, respectively, while it was increased by 53.3, 134.3, and 200.4%, respectively, with the same application rate of PLB. Compared to the PL, plant fresh weight increased by 33.68% after the application of PLB at 3%. The effectiveness of PLB application on plant weight was also suggested by Chan et al. [11] and Gunes et al. [45]. Inal et al. [46] stated that the weight of maize and bean was increased with an increasing dose of PLB treatments. Despite numerous positive reports, negative results were also found by some researchers. Allen [47] worked on PLB and observed decreased radish yield after the PLB application. In our experiment, the visual observation of plant growth revealed that the colors of the plants grown with PLB were greener than control and PL applied plants.

Though there are lots of positive results on the increase of yield after applying biochar, still there is controversy about the results as some scientists have given negative opinions. For example, Van Zwieten et al. [9] reported reduced growth in wheat and radish with the addition of a paper mill sludge biochar in a calcarosol. However, we found that most of the experiments revealed positive results on biochar application. Different experimental results conducted on biochar produced from different sources that represent positive results on plant growth are shown in Table 3. The application of both PL and PLB had a positive effect on the growth and yield of kangkong over control in this experiment. The growth of kangkong was improved by PL application as it is an excellent source of essential nutrients. Poultry litter itself is a valuable source of organic fertilizer for plant nutrients as it contains a high content of essential macro and micronutrients [17]. Biochar can boost plant development by improving soil physical (e.g., soil water-holding capacity, aggregate stability, aeration, and bulk density), chemical (e.g., nutrient-holding capacity, EC, pH, and CEC), and biological characteristics (e.g., rhizosphere microbial population, microbial biomass C, N, and enzymatic activities) [2, 48].

Biochar has been appeared to advance plant productivity and yield through several mechanisms. Physical situations change with biochar; its black color changes thermal dynamics and helps fast germination, permitting more time for growth compared with control [69]. Biochar can likewise improve soil water-holding capacity [70], empowering biomass gain [71]. Another way biochar may influence soil nutrients is through the decrease in leaching losses [72]. The porous structure, large surface area, and negative surface charge [3, 73,74,75] of biochar increase the CEC of soil and permit the retention of nutrients, such as K [76, 77] and P [72, 78]. Plant development can likewise be influenced by biochar-prompted changes in soil supplement conditions, especially the cycling of N, P, and K [79,80,81].

Moreover, biochar can raise plant-available water and soluble soil nutrient contents [3, 82]. Another mechanism responsible for this improvement could be that biochar served as a direct source of nutrients for plant uptake and changes in the soil chemical and physical properties caused by biochar [2, 26, 74, 83]. Since no fertilizers were applied in the soil in our experiment, the yield increases were mostly due to the ability of the PL and PLB to increase nutrient availability particularly N, P, and K. The PLB was reasonably high in total N and K (Table 1). It means the power of the PLB to release accessible N once applied within the soil via mineralization. It has experimented that the application of biochar increases the availability of N through mineralization and reduces the loss of N [11]. An opposite result was reported by previous research using biochar from plant origin [63]. In that study, biochar from green waste provided no positive yield effect on radish even when applied at a rate of 100 t ha−1 and this was recognized to the deficient N availability of the biochar used. During the pyrolysis process, significant quantities of biomass N are lost by volatilization [40]. The N remaining in the biochar tends to poorly available to plants [27] since a fraction of it is found inside aromatic C structures [40]. In our case, the biochar was from the animal origin that contained higher N. Higher N in biochars derived from animal manures was also reported by others [11, 84, 85]. P content was almost similar in both PL and PLB but higher than that of soil which was used for plant growth. Biochar helps to increase the availability of P is also reported [86], so the application of biochar enhanced P absorption by plants. Side by side, the increment of OC in PL and PLB helped to add OM in the soil which improved the soil quality and ultimately boost up plant growth.

4 Conclusion

The results of the study showed that the nutritional values, especially total N, K, Ca, and Mg, were increased distinctly in PLB after the pyrolysis of PL. In PLB, the total content of N, K, Ca, and Mg was 220, 170, 133 and 175% higher than that of PL. PLB also contained 57% more OC than that of PL, which represents PLB as a carbon-rich compound and results in an improvement of SOM as well as soil fertility. Moreover, Zn and S content in PLB was also increased by 100 and 33%, respectively, as compared to PL. The experimental results revealed that being a potential source of plant nutrients, both PL and PLB promoted the growth of kangkong compared to control, but the application of PLB contributed a better result of plant height and fresh weight than that of PL irrespective to the dose of application. Compared to the control, plant height increased by 14.3, 23.3, and 20.1% at 1, 2, and 3% of PL application, respectively, whereas PLB increased the plant height by 17.8, 34.4, and 32.4%, respectively, with the same application rate. However, the application of PLB increased plant height by 4.2, 16.9, and 18.2% as compared to the PL at 1, 2, and 3%, respectively. Plant fresh weight significantly increased by 70.4, 124.6, and 124.7% with compared to the control after the application of PL at 1, 2, and 3%, respectively, while it was increased by 53.3, 134.3, and 200.4%, respectively, with the same application rate of PLB. Nevertheless, compared to the PL, plant fresh weight increased by 4.32 and 33.68% after the application of PLB at 2 and 3%, respectively. It indicates that when PL was used as PLB, its fertilizing capacity enhanced and influenced the plant growth. The results also showed that plant growth increased with an increasing dose of treatment, and the best performance was observed under 3% PLB application. So, the production of PLB from PL might be a very effective management strategy of PL and could be a stable and nutrient-rich promising organic fertilizer which will help for maintaining sustainable agriculture.

References

Lehmann J, Gaunt J, Rondon M (2006) Biochar sequestration in terrestrial ecosystems–a review. Mitig Adapt Strateg Glob Change 11:403–427. https://doi.org/10.1007/s11027-005-9006-5

Lehmann J, Joseph S (2009) Biochar for environmental management: an introduction. In: Lehmann J, Joseph S (eds) Biochar for environmental management: science and technology. Earthscan, London, pp 1–9

Novak JM, Lima I, Xing B, Gaskin JW, Steiner C, Das KC, Ahmedna M, Rehrah D, Watts DW, Busscher WJ, Schomberg H (2009) Characterization of designer biochar produced at different temperatures and their effects on loamy sand. Ann Environ Sci 3:195–206

Scholz SM, Sembres T, Roberts K, Whitman T, Wilson K, Lehmann J (2014) Biochar systems for smallholders in developing countries leveraging current knowledge and exploring future potential for climate-smart agriculture. Washington D.C, The world bank. https://doi.org/10.1596/978-0-8213-9525-7

Widowati UWH, Guritno B, Soehono LA (2012) The effect of biochar on the growth and N fertilizer requirement of Maize (Zea mays L) in a greenhouse experiment. J Agric Sci 4:255–262. https://doi.org/10.5539/jas.v4n5p255

Mohan D, Pittman CU Jr, Bricka M, Smith F, Yancey B, Mohammad J, Steele PH, Alexandre-Franco MF, Gómez-Serrano V, Gong H (2007) Sorption of arsenic, cadmium, and lead by chars produced from fast pyrolysis of wood and bark during bio-oil production. J Colloid Interface Sci 310:57–73. https://doi.org/10.1016/j.jcis.2007.01.020

Lu H, Li Z, Fu S, Méndez A, Gascó G, Paz-Ferreiro J (2015) Effect of biochar in cadmium availability and soil biological activity in an anthrosol following acid rain deposition and aging. Water Air Soil Pollut 226:164–174. https://doi.org/10.1007/s11270-015-2401-y

Warnock DD, Lehmann J, Kuyper TW, Rillig MC (2007) Mycorrhizal responses to biochar in soil-concepts and mechanisms. Plant Soil 300:9–20. https://doi.org/10.1007/s11104-007-9391-5

Van Zwieten L, Kimber S, Morris S, Chan KY, Downie A, Rust J, Joseph S, Cowie A (2010) Effects of biochar from slow pyrolysis of paper mill waste on agronomic performance and soil fertility. Plant Soil 327:235–246. https://doi.org/10.1007/s11104-009-0050-x

Steiner C, Teixeira WG, Lehmann J, Nehls T, de Macedo JLV, Blum WEH, Zech W (2007) Long-term effects of manure, charcoal and mineral fertilization on crop production and fertility on a highly weathered Central Amazonian upland soil. Plant Soil 291:275–290. https://doi.org/10.1007/s11104-007-9193-9

Chan KY, Van Zwieten L, Meszaros I, Downie D, Joseph S (2008) Using poultry litter biochars as soil amendments. Soil Res 46:437–444. https://doi.org/10.1071/SR08036

FAO (2006) World agriculture: towards 2030/2050. Interim report. Food and agriculture organization of the United Nations. Prospects for food, nutrition, agriculture and major commodity groups, Rome

Islam MK, Uddin MF, Alam MM (2014) Challenges and prospects of poultry industry in Bangladesh. Eur J Bus Manage 6:116–127

BER, Bangladesh Economic Review (2013) Ministry of Finance, Government of the People’s Republic of Bangladesh, pp 87–103

Waste Concern (2005) CDM Project potential in poultry waste management sector in Bangladesh. https://www.wasteconcern.org/Publication/Poultry%2520Final.pdf. Accessed 24 July 2019

Bolan NS, Szogi AA, Chuasavathi T, Seshadri B, Rothrock MJJ, Panneerselvam P (2010) Uses and management of poultry litter. World's Poult Sci 66:673–698. https://doi.org/10.1017/S0043933910000656

Dikinya O, Mufwanzala N (2010) Chicken manure enhanced soil fertility and productivity: effects of application rates. J Soil Sci Environ Manage 1(3):46–54

Reddy KC, Reddy SS, Malik RK, Lemunyon JL, Reeves DW (2008) Effect of five-year continuous poultry litter use in cotton production on major soil nutrients. Agron J 100:1047–1055. https://doi.org/10.2134/agronj2007.0294

Abdullah-Al-Amin M, Rahman MS, Howlider MAR, Ahmmed MM (2009) Disposal of layer droppings reared in case and impact on environmental pollution. J Bangladesh Agril Univ 7:281–290. https://doi.org/10.3329/jbau.v7i2.4735

Akanni KA, Benson OB (2014) Poultry wastes management strategies and environmental implications on human health in the Ogun State of Nigeria. Advances Econ Bus, 2 164–171 10.13189/aeb.2014.020402

Jenkins MB, Endale DM, Schomberg HH, Sharpe RR (2006) Fecal bacteria and sex hormones in soil and runoff from cropped watersheds amended with poultry litter. Sci Total Environ 358:164–177. https://doi.org/10.1016/j.scitotenv.2005.04.015

Pappas EA, Kanwar RS, Baker JL, Lorimor JC, Mickelson S (2008) Fecal indicator bacteria in subsurface drain water following swine manure application. Trans ASABE 51:1567–1573

Draper K, Tomlinson T (2012) Poultry litter biochar- a US perspective. International Biochar Initiative (IBI)

Karim Z, Iqbal A (2001) Impact of land degradation in Bangladesh: a changing scenario in agricultural land use. Bangladesh Agricultural Research Council. Soils publication:42. Farmgate, Dhaka, pp 60–160

Islam MS (2006) Use of bio-slurry as organic fertilizer in Bangladesh agriculture. Prepared for presentation at the international workshop on the use of bio-slurry domestic biogas programmes. pp 27–28 September, Bangkok, Thailand

Asai H, Samson BK, Stephan HM, Songyikhangsuthor K, Homma K, Kiyono Y, Inoue Y, Shiraiwa T, Horie T (2009) Biochar amendment techniques for upland rice production in Northern Laos 1. Soil physical properties, leaf SPAD and grain yield. Field Crops Res 111:81–84. https://doi.org/10.1016/j.fcr.2008.10.008

Gaskin JW, Speir RA, Harris K, Das KC, Lee RD, Morris LA, Fisher DS (2010) Effect of peanut hull and pine chip biochar on soil nutrients, corn nutrient status, and yield. Agron J 102:623–633. https://doi.org/10.2134/agronj2009.0083

Mondal MRI, Sultan MK, Nur S, Sarkar MJU, Alam MS, Rahman MHH (2014) Krishi proyukti hatboi (Handbook of agro-technology), 6th edn. Bangladesh Agricultural Research Institute, Gazipur, p 1701

USDA (1951) United States Department of Agriculture. Soil survey manual. Soil survey staff, Bureau of plant industry, soils and agricultural engineering, USDA, Handbook-18. Washington, USA

Baldock JA, Smernik RJ (2002) Chemical composition and bioavailability of thermally altered Pinus resinosa (red pine) wood. Org Geochem 33:1093–1109. https://doi.org/10.1016/S0146-6380(02)00062-1

Abbasi MK, Anwar AA (2015) Ameliorating effects of biochar derived from poultry manure and white clover residues on soil nutrient status and plant growth promotion-greenhouse experiments. PLoS ONE 10(6):e0131592. https://doi.org/10.1371/journal.pone.0131592

Vijayanand C, Kamaraj S, Sriramajayam S, Ramesh D (2016) Biochar production from areca nut waste. Int J Farm Sci 6:43–48

Brownsort PA (2009) Biomass pyrolysis processes: performance parameters and their influence on biochar system benefits. Edinburgh: UK Biochar Research Centre - SCCS Consortium. A dissertation presented for the degree of Master of Science University of Edinburgh

Jackson ML (1973) Soil chemical analysis. New Delhi, Prentice-Hall of India Pvt Ltd., p 498

Walkley A, Black IA (1934) An examination of degtjareff method for determining soil organic matter and a proposed modification of the chromic acid titration method. Soil Sci 37:29–38. https://doi.org/10.1097/00010694-193401000-00003

Murphy J, Riley JP (1962) A modified single solution method for the determination of phosphate in natural water. Anal Chim Acta 27:31–36. https://doi.org/10.1016/S0003-2670(00)88444-5

Imamul Huq SM, Alam MD (2005) A handbook on analysis of soil, plant and water. University of Dhaka, Bangladesh, BACER-DU

Cantrell KB, Hunt PG, Uchimiya M, Novak JM, Ro KS (2012) Impact of pyrolysis temperature and manure source on physicochemical characteristics of biochar. Bioresour Technol 107:419–428. https://doi.org/10.1016/j.biortech.2011.11.084

Kazi ZH, Schnitzer MI, Monreal C, Mayer P (2011) Separation and identification of heterocyclic nitrogen compounds in bio-oil derived by fast pyrolysis of chicken manure. J Environ Sci Health 46:51–61. https://doi.org/10.1080/03601234.2010.515506

Chan KY, Xu Z (2009) Biochar: nutrient properties and their enhancement. In: Lehmann J, Joseph S (eds) Biochar for environmental management: science and technology. Earthscan, London, pp 67–84

Cely P, Gascó G, Paz-Ferreiro J, Méndez A (2015) Agronomic properties of biochars from different manure wastes. J Anal Appl Pyrolysis 111:173–182

Knoepp JD, DeBano LF, Neary DG (2005) Soil chemistry. In: Neary DG, Ryan KC, DeBano LF (eds) Wildland fire in ecosystems: effects of fire on soils and water. RMRS-GTR 42, vol 4, USDA, forest service, Rocky mountain research station, Ogden, UT. pp 53–71

Bhattarai B, Neupane J, Dhakal SP, Nepal J, Gnyawali B, Timalsina R, Poudel A (2015) Effect of biochar from the different origin on physio-chemical properties of soil and yield of garden pea (Pisum sativumL) at Paklihawa Rupandehi Nepal. World J Agric Res 3: 129–138 https://doi.org/10.12691/wjar-3-4-3

Maru A, Haruna OA, Primus WC (2015) Co-application of chicken litter biochar and urea only to improve nutrients use efficiency and yield of Oryza sativa L. Cultivation on a tropical acid soil. Sci World J 2015:1 12. https://doi.org/10.1155/2015/943853

Gunes A, Inal A, Taskin MB, Sahin O, Kaya EC, Atakol A (2014) Effect of phosphorus-enriched biochar and poultry manure on growth and mineral composition of lettuce (Lactuca sativa L.) grown in alkaline soil. Soil Use Manag 30:182–188. https://doi.org/10.1111/sum.12114

Inal A, Gunes A, Sahin O, Taskin MB, Kaya EC (2015) Impacts of biochar and processed poultry manure, applied to a calcareous soil, on the growth of bean and maize. Soil Use Manag 31(1):106–113. https://doi.org/10.1111/sum.12162

Allen JM (2014) The effects of poultry litter biochar and water source on radish growth and nutrition. Crop Soil Environ Sci 9:3–4 University of Arkansas, Fayetteville

Sohi SP, Krull E, Lopez-Capel E, Bol R (2010) A review of biochar and its use and function in soil. Adv Agron 105:47–82

Ding Y, Liu Y, Liu S, Li Z, Tan X, Huang X, Zeng G, Zhou L, Zheng B (2016) Biochar to improve soil fertility a review. Agron Sustain Dev 36(2):36. https://doi.org/10.1007/s13593-016-0372-z

Al-Wabel MI, Hussain Q, Usman ARA, Ahmad M, Abduljabbar A, Sallam AS, Ok YS (2017) Impact of biochar properties on soil conditions and agricultural sustainability: a review. Land Degrad Dev 29(7):2124–2161. https://doi.org/10.1002/ldr.2829

Shareef TME, Zhao BW (2017) Review paper: The fundamentals of biochar as a soil amendment tool and management in agriculture scope: an overview for farmers and gardeners. J Agric Chem Environ 6:38–61. https://doi.org/10.4236/jacen.2017.61003

Palansooriya KN, Ok YS, Awad YM, Lee SS, Sung JK, Koutsospyros A, Moon DH (2019) Impacts of biochar application on upland agriculture: a review. J Environ Manage 234:52–64

Liu L, Wang Y, Yan X, Li J, Jiao N, Hu S (2017) Biochar amendments increase the yield advantage of legume-based intercropping systems over monoculture. Agric Ecosyst Environ 237:16–23

Liu Z, Chen X, Jing Y, Li Q, Zhang J, Huang Q (2014) Effects of biochar amendment on rapeseed and sweet potato yields and water-stable aggregate in upland red soil. CATENA 123:45–51. https://doi.org/10.1016/j.catena.2014.07.005

Zhang A, Cui L, Pan G, Li L, Hussain Q, Zhang X, Zheng J, Crowley D (2010) Effect of biochar amendment on yield and methane and nitrous oxide emissions from a rice paddy from Tai Lake Plain, China. Agric Ecosyst Environ 139:469–475. https://doi.org/10.1016/j.agee.2010.09.003

Kim H-S, Kim K-R, Yang JE, Ok YS, Owens G, Nehls T, Wessolek G, Kim K-H (2016) Effect of biochar on reclaimed tidal land soil properties and maize (Zea mays L.) response. Chemosphere 142:153–159

Peng X, Ye LL, Wang CH, Zhou H, Sun B (2011) Temperature- and duration-dependent rice straw-derived biochar: characteristics and effects on soil properties of a Ultisol in Southern China. Soil Till Res 112:159–166. https://doi.org/10.1016/j.still.2011.01.00

Van Zwieten L, Rose T, Herridge D, Kimber S, Rust J, Cowie A, Morris S (2015) Enhanced biological N2 fixation and yield of faba bean (Vicia faba L.) in an acid soil following biochar addition: dissection of causal mechanisms. Plant Soil 395:7–20. https://doi.org/10.1007/s11104-015-2427-3

Uzoma KC, Inoue M, Andry H, Fujimaki H, Zahoor A, Nishihara E (2011) Effect of cow manure biochar on maize productivity under sandy soil condition. Soil Use Manage 27:205–212. https://doi.org/10.1111/j.1475-2743.2011.00340.x

Rogovska N, Laird DA, Rathke SJ, Karlen DL (2014) Biochar impact on Midwestern Mollisols and maize nutrient availability. Geoderma 230:340–347. https://doi.org/10.1016/j.geoderma.2014.04.009

Arif M, Ali K, Jan MT, Shah Z, Jones DL, Quilliam RS (2016) Integration of biochar with animal manure and nitrogen for improving maize yields and soil properties in calcareous semi-arid agroecosystems. Field Crops Res 195:28–35. https://doi.org/10.1016/j.fcr.2016.05.011

Bhattacharjya S, Chandra R, Pareek N, Raverkar KP (2015) Biochar and crop residue application to soil: Effect on soil biochemical properties, nutrient availability and yield of rice (Oryza sativa L.) and wheat (Triticum aestivum L.). Arch Agron Soil Sci 62 8 1095–108 https://doi.org/10.1080/03650340.2015.1118760

Chan KY, Van Zwieten L, Meszaros I, Downie A, Joseph S (2007) Agronomic values of green waste biochar as a soil amendment. Aust J Soil Res 45:629–634. https://doi.org/10.1071/SR07109

Genesio L, Miglietta F, Baronti S, Vaccari FP (2015) Biochar increases vineyard productivity without affecting grape quality: results from a four years field experiment in Tuscany. Agric Ecosyst Environ 201:20–25. https://doi.org/10.1016/j.agee.2014.11.021

Raboin L-M, Razafimahafaly AHD, Rabenjarisoa MB, Rabary B, Dusserre J, Becquer T (2016) Improving the fertility of tropical acid soils: liming versus biochar application? a long term comparison in the highlands of Madagascar. Field Crops Res 199:99–108

Jaiswal AK, Elad Y, Graber ER, Frenkel O (2014) Rhizoctonia solani suppression and plant growth promotion in cucumber as affected by biochar pyrolysis temperature, feedstock, and concentration. Soil Biol Biochem 69:110–118

Hossain MK, Strezov V, Chan YK, Nelson PF (2010) Agronomic properties of wastewater sludge biochar and bioavailability of metals in the production of cherry tomato (Lycopersicon esculentum). Chemosphere 78:1167–1171. https://doi.org/10.1016/j.chemosphere.2010.01.009

Glaser B, Lehmann J, Zech W (2002) Ameliorating physical and chemical properties of highly weathered soils in the tropics with charcoal–a review. Biol Fertil Soils 35:1719–1730. https://doi.org/10.1007/s00374-002-0466-4

Genesio L, Miglietta F, Lugato E, Baronti S, Pieri M, Vaccari FP (2012) Surface albedo following biochar application in durum wheat. Environ Res Lett 7(1):014025. https://doi.org/10.1088/1748-9326/7/1/014025

Laird DA, Fleming P, Davis DD, Horton R, Wang B, Karlen DL (2010) Impact of biochar amendments on the quality of a typical midwestern agricultural soil. Geoderma 158:443–449

Kammann CI, Linsel S, Goßling JW, Koyro HW (2011) Influence of biochar on drought tolerance of Chenopodium quinoa willd. and on soil-plant relations. Plant Soil 345:195–210

Laird D, Fleming P, Wang B, Horton R, Karlen D (2010) Biochar impact on nutrient leaching from a Midwestern agricultural soil. Geoderma 158:436–442

Bird MI, Ascough PL, Young IM, Wood CV, Scott AC (2008) X-ray microtomographic imaging of charcoal. J Archaeol Sci 35:2698–2706

Cheng C-H, Lehmann J, Engelhard MH (2008) Natural oxidation of black carbon in soils: changes in molecular form and surface charge along a climosequence. Geochim Cosmochim Acta 72:1598–1610

Downie A, Crosky A, Munroe P (2009) Physical properties of biochar. In: Lehmann J, Joseph S (eds) Biochar for environmental management. Earthscan, London, pp 13–29

Liang B, Lehmann J, Solomon D, Kinyangi J, Grossman J, O’neill B, Skjemstad JO, Thies J, Luizão FJ, Petersen J, Neves EG (2006) Black carbon increases cation exchange capacity in soils. Soil Sci Soc Am J 70(5):1719–1730

Major JA, Rondon M, Molina D, Riha SJ, Lehmann J (2011) Nutrient leaching in a Columbian savanna oxisol amended with biochar. J Environ Qual 41:1076–1086

Beck DA, Johnson GR, Spolek GA (2011) Amending green roof soil with biochar to affect runoff water quantity and quality. Environ Pollut 159:2111–2118

Dempster N, Gleeson B, Solaiman M, Jones L, Murphy V (2012) Decreased soil microbial biomass and nitrogen mineralization with eucalyptus biochar addition to a coarse-textured soil. Plant Soil 354:311–324

Dempster N, Jones L, Murphy V (2012) Organic nitrogen mineralization in two contrasting agroecosystems is unchanged by biochar addition. Soil Biol Biochem 48:47–50

Taghizadeh-Toosi A, Clough TJ, Sherlock RR, Condron LM (2012) Biochar adsorbed ammonia is bioavailable. Plant Soil 350:57–69

Sun HJ, Lu HY, Chu L, Shao HB, Shi WM (2017) Biochar applied with appropriate rates can reduce N leaching, keep N retention and not increase NH3 volatilization in coastal saline soil. Sci Total Environ 575:820–825

Jeffery S, Verheijen FGA, van der Velde M, Bastos AC (2011) A quantitative review of the effects of biochar application to soils on crop productivity using meta-analysis. Agric Ecosyst Environ 144:175–187

Tagoe SO, Horiuchi T, Matsui T (2008) Effects of carbonized and dried chicken manures on the growth, yield, and N content of soybean. Plant Soil 306:211–220

Tagoe SO, Horiuchi T, Matsui T (2008) Preliminary evaluation of the effects of carbonized chicken manure, refuse-derived fuel and K fertilizer application on the growth, nodulation, yield, N and P contents of soybean and cowpea in the greenhouse. Afr J Agric Res 3:759–774

Park JH, Choppala GK, Bolan NS, Chung JW, Chuasavathi T (2011) Biochar reduces the bioavailability and phytotoxicity of heavy metals. Plant Soil 348:439–451. https://doi.org/10.1007/s11104-011-0948-y

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Joardar, J.C., Mondal, B. & Sikder, S. Comparative study of poultry litter and poultry litter biochar application in the soil for plant growth. SN Appl. Sci. 2, 1770 (2020). https://doi.org/10.1007/s42452-020-03596-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-020-03596-z