Abstract

The aim of this work was to evaluate the potential of cellulose nanofibrils (CNFs) films treated with commercial solution of Ag nanoparticles stabilized with natural tannin and silane groups in the bacteria growth inhibition. The films were produced with commercial pulps of pine and eucalyptus treated with sodium hydroxide (5% w/v) and calcium hydroxide (10% w/v), respectively. The bacteria selected for the inhibition test were the gram-positive Listeria monocytogenes and gram-negative Salmonella enteriditis. The films performance was investigated by the antimicrobial activity using disc diffusion. In addition, the pulps were evaluated by their chemical composition, water retention index (WRI) and X-ray diffraction (XRD). The content of hemicelluloses in the treated pine pulp (11.32%) was lower in comparison to the found in the treated eucalyptus pulp (14.46%). The XRD diffractogram presented higher crystallinity index for the treated eucalyptus pulp (70%) with a characteristic peak of calcium carbonate. The treated eucalyptus pulp showed higher WRI and viscosity values in relation to the treated pine pulp. Growth inhibitory halos were more expressive when the treatment with both antimicrobial solutions were proceeded in the films produced with pine CNFs with addition of the citric acid. The effect of the nanoparticles stabilized with tannin must be highlighted, mainly on the bacterium S. enteriditis.

Similar content being viewed by others

1 Introduction

The safety against pathogenic microorganisms provided by packaging has been a subject of great concern to the manufacturers, especially when it comes to food products. In the attempt to provide the consumer a product free of contamination by pathogenic microorganisms, researches have been done in the development of films for packaging which could have an antimicrobial potential. Among the different types of material used for films production, the literature reports the following as the most common: cassava starch [1], fish gelatin [2], whey protein isolate [3] and the cellulose nanofibrils (CNFs) [4,5,6]. Currently, there is a great interest in materials obtained directly from natural resources, as cellulose derivatives, due to its biodegradable characteristics [7]. With higher surface area and better mechanical properties in relation to non-fibrillated cellulose, films from CNFs have a promising potential. Also, certain nanocomposites have expanded the application of nanostructured films in various industrial applications due to their antimicrobial functions. Several antimicrobial agents have been used in association with polymer matrices for production of films for inhibition of bacterial growth, such as: citric acid [3], ascorbic acid [8], sorbic acid [7], sodium benzoate [9], chitosan [10], sulfur nanoparticles [11] and silver nanoparticles [12]. The noble metals as silver nanoparticles have been widely used in terms of safety against many pathogenic microorganisms. The usage of synthetic molecules to stabilize the nanoparticles often creates health and environmental issues. These nanoparticles can be used in association with other compounds in order to increase their effectiveness as an antimicrobial. Encapsulation with silane groups, for example, can functionalize the nanoparticle as an anchor for other chemical groups. On the other hand, the encapsulation with tannins allows antimicrobial synergy with silver. In both cases, the molecules also function as stabilizers of nanoparticles, and are used for their versatility to resist the conditions of the synthesis during the industrial process. In particular, dispersions of alkaline nanoparticles, mainly calcium and magnesium hydroxide in nonaqueous solvents, have been proposed as efficient deacidifying treatments for cellulose-based works of art, such as paper [13], manuscripts [14] and archeological wood [15]. These nanoparticles, due to their high reactivity, provide a stable neutral environment by rapidly turning into mild alkaline species (carbonates). Citric acid has been reported to crosslink polysaccharides [16, 17]. The crosslinking mechanism of citric acid is ascribed to covalent di-ester linkages between hydroxyl groups of two different polysaccharide chains and two carboxyl groups of citric acid [17, 18]. The advantage that any unreacted citric acid may also act as a plasticizer [19, 20]. The use of antimicrobial particles in conjunction with stabilizers and other components can be effective against bacteria such as the genera Salmonella and Listeria. Salmonella enteriditis is a pathogenic gram-negative bacterium causing diarrhea, fever and abdominal spasm. Its external (lipopolysaccharide) fraction determines its toxigenicity and antigenicity. Salmonella can also intervene into the blood stream, bones, brain and nervous system and can occasionally result in lethal infections [21]. The cell wall in gram negative bacteria is chemically more complex, having a greater amount of aminoacids and lipids. Listeria monocytogenes has a strong adaptability to the external environment and can survive at refrigerated temperatures and high salt concentrations [22]. The aim of this work was to evaluate the potential of CNFs films treated with tannin-stabilized silver nanoparticles commercial solution and citric acid, in the inhibition of the Listeria monocytogenes and Salmonella enteriditis growth.

2 Materials and methods

2.1 Pulp treatments

The pine and eucalyptus sheets were provided by Klabin (Itajaí—Santa Catarina, SC, Brazil). The sheets were manually torn and passed by a hydration process during 24 h. The eucalyptus pulp was treated with calcium hydroxide 10% (w/v) (Ca(OH)2) aqueous solution in proportion 1:40 (w/v). The procedure consists of the initial reaction of the pulp with Ca(OH)2, with exposure to a source of carbon dioxide (CO2) which in presence of moisture will promote the calcium carbonate formation (CaCO3) within the fibers. The Ca(OH)2 is a compound which shows a high dissolubility degree, reacting quickly with CO2 for CaCO3 formation. During the carbonation reaction, CO2 is widespread through the fibers unsaturated pores. The CO2 diffuses in the aqueous phase present of the pores transforming into carbonic acid (H2CO3), dissociating into ions HCO3− and CO3−, with the dissolution of Ca(OH)2 which releases ions Ca2+ and OH−, and precipitate forming the CaCO3 (Eq. 1):

The pulp (60 g dried) was treated with aqueous solution of Ca(OH)2 in water bath at 60 °C under constant stirring at 700 rpm for 3 h. The pine pulp was treated with sodium hydroxide (NaOH) (w/v) 5% aqueous solution in a water bath at 80 °C under constant stirring at 1000 rpm for 2 h. In the end of the reaction, the both pulps were washed with distilled water until the neutral pH.

2.2 Antimicrobial solutions

The antimicrobial products were obtained from TNS Nanotecnologia LTDA (Florianópolis—Santa Catarina, SC, Brazil) Ag based antimicrobial additive in aqueous solution. Applied in textiles, paints, varnishes and others. The Ag concentration in the solutions was close to 0.1–2.0%. Two different types of antimicrobial solutions were used. The first type was an antimicrobial product composed by Ag nanoparticles encapsulated with biocompatible natural tannin molecules (NpAg_TAN). The second type was an antimicrobial product composed by Ag nanoparticles functionalized with silane groups (NpAg_925). In both solutions, the nanoparticles were in range from 5 to 20 nm.

2.3 Preparation of CNF films

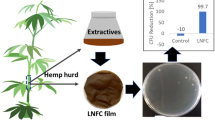

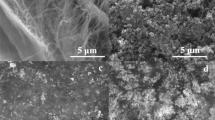

The nanofibrils were obtained by nanofibrillation through a SuperMasscolloider grinder (Masuko Sangyo MKCA6-3) using opening between disks of 0.01 mm and grindstone rotation of 1600 rpm. Two types of nanofibrillated pulps were used for production of the films: (1) commercial pine pulp treated with NaOH (5% w/v); (2) commercial eucalyptus pulp treated with Ca(OH)2 (10% w/v) (Fig. 1). The films were produced from the suspension obtained after 40 cycles of defibrillation. The micro/nanostructure of the CNFs was investigated by transmission scanning microscopy (TEM) using a Tecnai G2-12 (FEI Company, United States) instrument with an accelerated voltage of 80 kV. Sample preparation and TEM configurations followed recommendations described elsewhere [23]. The CNF films were prepared by casting, using 40 mL suspensions (1% w/v) in acrylic petri dishes with 15 cm diameter.

Four films of each CNF condition were produced and dried at room temperature. Anhydrous citric acid (99.5%, ACS grade), purchased from Labsynth® (Diadema, SP, Brazil), was added to the suspension of nanofibrils at a 10 g/100 g (based on dried mass of the nanofibrils). The film samples were obtained with a diameter of 6 mm. The samples were separated into two groups, one group being treated with NpAg_Tan and the other group with the NpAg_925. One drop of each type of antimicrobial compound was dripped over each sample (Fig. 2). In total, eight treatments were evaluated (Table 1).

A sample of antibiotic film (Chloramphenicol 30), obtained from Bioanalyse® (Ankara, Turkey) was added in each petri dish as “control treatment”.

2.4 Microorganisms and inocula standardization

The bacteria Salmonella enteritidis S64 and Listeria monocytogenes ATCC 19117 were used in the evaluation. The strains were obtained from the Reference Bacteria Collection in Surveillance Sanitary, National Institute of Health Quality Control (INCQS), Oswaldo Cruz Foundation (FIOCRUZ, Rio de Janeiro, RJ, Brazil) and in the Tropical Culture collection, André Tosello Foundation (Campinas, São Paulo, Brazil). The reactivation of the culture was done in Brain Heart Infusion broth (BHI) in 37 °C of temperature during 24 h. The cell suspensions were standardized in about 108 UFC/mL, using 0.5 as turbidity standard of the MacFarland scale.

2.5 Evaluation of antimicrobial activity

The disc diffusion techniques described in CLSI [24] were used for the evaluation of antimicrobial activity. Standardized suspensions aliquots of 100 µL of each bacterial culture were inoculated on agar BHI (Brain Heart Infusion). After the scattering, the plates were divided into 4 quadrants and the 6 mm diameter film discs were disposed equidistantly in each quadrant. Three films were deposited in each quadrant, for each bacteria. The plates were incubated at 37 °C for 24 h and the inhibition halos were measured with a digital caliper.

2.6 Chemical composition of the pulps

The quantification of acid insoluble lignin and acid soluble lignin for treated pine and eucalyptus pulps followed the described in Gomide and Demuner [25] and Goldschimid [26], respectively. The analysis of polysaccharides glucose, xylose, arabinose and mannose were done through the described in Wallis et al. [27]. In eucalyptus pulp, the cellulose content is equal to the glucose content, while the hemicelluloses correspond to the xylose content. For pine pulp, every three units of mannose are linked to one unit of glucose, being hemicelluloses content the sum of mannose, respective glucose ratio, arabinose and xylose. For the cellulose content of pine pulp, the glucose content was subtracted from the fraction related to mannose.

2.7 Viscosity of the pulps

The viscosity of the treated pine and eucalyptus pulps was determined by capillary viscosimetry using the capillary viscometer Cannon-Fensk. The samples of the pulps were dissolved in cupric ethylenediamine and the time required for the solution go through the distance between the viscometer marks was recorded according to the TAPPI 230 [28]. Two measurements were carried out from which a mean time of flowing was obtained to determine the viscosity according to the Eq. 2.

where η is the solution viscosity at 25 °C (cP); K is the viscometer constant (determined from a known viscosity substance); d is the density of the cupric solution of the pulp (1.052 g/cm3); t is flow time (s).

2.8 Water retention index

Water retention index (WRI) of the pulps were determined dispersing them in water at a fiber content of 0.5% (w/t) after boiling it in water for 5 min. Water suspension was filtered by a centrifugal force of 3000 G for 15 min for dewatering, and the wet filtered pulps were weighed. After they oven-drying at 110 °C for 5 h, the weight was measured again. The WRI was determined according to Eq. 3:

where W0 and W1 are the mass of the wet and oven-dried pulps, respectively.

2.9 X-ray diffraction (XRD)

Crystalline structures of the fibers and CNFs were analyzed by a XRD 600 (Rigaku®) difractometer with CuKα radiation (λ = 1.540 Å) at 30 kV and 30 mA over the angular range 2θ = 5°–37.5° at a rate of 2θ/min. The fibers were compressed in an aluminum sample holder furrows. The crystallinity index (CI) was calculated from the ratio between the area below all the crystalline peaks and the total area below the whole curve, determined after deconvolution (including the non-crystalline fraction) following the Eq. (4).

3 Results and discussion

The mean halos of bacterial grown inhibition were higher in diameter for the films produced with pine CNFs (Table 2). The lowest growth inhibition halo observed for eucalyptus films (compared to the other) may be due to the non-migrant and stable characteristic of the nanoparticles in the fiber structure. The treatment of the commercial eucalyptus pulp with Ca(OH)2 left residues of CaCO3 (see Fig. 1) in the CNFs produced, generated by the reaction of the Ca(OH)2 with CO2, which may have resulted in entrapment of silver nanoparticles. This fact may have reduced the effect of nanoparticles as antimicrobial agents and prevented the formation of an extended halo for eucalyptus CNFs films. In addition, it can be seen that both antimicrobial solutions were more efficient at inhibiting the bacterial growth of Salmonella enteriditis.

The bacterial cell wall is constituted of a mucocomplex which includes, among others, peptidoglycan, murein, mucopeptide or glycopeptide. The bacterium Salmonella enteriditis is known to be gram negative. In gram negative bacteria this complex represents a smaller fraction of the total cell wall in relation to the gram positive. The thinner cell wall favored the access of the silver nanoparticles to the interior of the bacterial cell, which resulted in higher efficiency of the antimicrobial solutions against Salmonella bacteria. Bacteria such as Listeria monocytogenes is known to be classified as gram positive. In some bacteria with structurally gram positive walls the lipids are in greater quantity and strongly connected, composing about 60% of the dry weight of the wall [29]. The thicker lipid layer acts as a barrier to the passage of the nanoparticles resulting in a smaller amount of nanoparticles reaching the center of the cell.

Concerning the bacteria Salmonella, the larger diameter inhibition halos were observed for the films PacTAN, in which the silver nanoparticles were stabilized with tannins, and Pac925 stabilized with silane grups (Fig. 3). Tannins are able to stabilize nanoparticle though their phenolic hydroxyls and quinones formed from the oxidation of phenolic hydroxyls [30]. Since tannins are natural compounds extracted from various parts of the plants such as leaves and bark, the stabilization of nanoparticles with these compounds could be a positive point considering sustainability factors. On the other hand, the silane groups can increase the anchorage of the nanoparticles with the nanofibrils. Considerable literature has demonstrated that a silane coupling based agent can act as an adhesion promoter by being capable of reacting with a metal adherent [31, 32] and a polymer [33].

In the case of the two commercial solutions, it can be said that their antimicrobial effects were potentiated in the treatments which there was also the addition of citric acid in the CNFs. The literature reports the increased efficiency of other agents with antimicrobial potential when used with citric acid. The combination of acetic and citric acids showed higher antimicrobial activity than when acetic acid was used individually against Escherichia coli [34].

As previously discussed, the halos observed for Listeria monocytogenes were less expressive. The presence of small halos does not indicate nullity of antimicrobial agents. Even if the inhibition halo is not very expressive, it is enough to attest to the antimicrobial activity (Figs. 4, 5). The non-migration characteristic is linked to the entrapment and anchoring of the nanoparticles in the fiber matrix, and contributes to the non-dilution of the active substance along the inhibition halo (as can happen with migrant antibiotics). This characteristic of migrant dilution compounds may contribute to the formation of resistant bacteria due to the antibiotic dose reduces along the radius of the halo. This halo is responsible for the formation of resistant bacteria, since the bacteria that are in the halo extremity receive low concentrations of antibacterial assets and that end up not being eliminated, generating a resistant lineage. In this way, it can be said that the commercial solutions evaluated in this study have antimicrobial characteristics.

Pre-treatments performed on pulps before the defibrillation may influence the characteristics of CNFs as regards the potential for receiving treatments with antimicrobial solutions. It can be seen that the treated eucalyptus pulp presented higher WRI and viscosity compared to the treated pine pulp (Fig. 6). The treatment of the eucalyptus commercial pulp with Ca(OH)2, which is an extremely hydrophilic base, caused a higher bonding with the hydroxyl groups present in the water. The bonds between the treatment agent and the CNFs may have impaired a more effective anchoring of the nanoparticles present in the antimicrobial solution with the CNFs. In addition, the treatment of the eucalpytus pulps generated carbonate residues in the CNFs, contributing to increase the viscosity.

The treatment of the commercial pinus pulp with NaOH resulted in nanofibrils with lower viscosity and WRI. The chemical analysis of the treated commercial pulps showed higher levels of hemicellulose in the eucalyptus pulp (Table 3). Hemicelluloses are known to have greater affinity for water in comparison to cellulose [35]. Generally these wood components can be removed in presence of strong alkali chemical compounds as NaOH or KOH. Scatolino et al. [6] performing the alkaline treatment on natural fibers of the Amazonian paricá, verified a reduction of 50% in the extractives content of the material and a great removal of hemicelluloses. Another point to be observed is the low content of xylose in the pine pulp. Xyloses are compounds generated from the hydrolysis of xylans. The xylans are hemicelluloses easily removable in the presence of alkali. This facility is attributed to its amorphous structure, as it contains a large number of acid groups that favor the reactions of these hemicelluloses with sodium hydroxide during the kraft process [36].

The amount of cellulose in the pine pulps was higher in relation to the eucalyptus pulps. Regarding the addition of antimicrobial solutions to the films, the amount of cellulose present in the pulp is an important factor for the anchoring of silver nanoparticles. The satisfactory amount of cellulose can facilitate the stabilization of the nanoparticles with silane groups, tannins and also with citric acid. The tannins act in a way that the silver nanoparticles are stabilized by unreacted phenolic hydroxyls as well as quinones through electron donation/acception interactions [37]. On the other hand, the silane groups act by functionalizing the nanofibrils and allowing the anchoring of new chemical groups. These considerations, added to the fact that pine pulp have a higher content of cellulose, may have resulted in grater inhibition halos for films of pine nanofibrils.

The chemical composition and treatments of the pulps also exert a high influence when evaluating the crystallinity of the CNFs. It is noted that the crystallinity index of the eucalyptus pulp treated with Ca(OH)2 was higher in comparison with the pine pulp treated with NaOH (Fig. 7).

The pattern of the treated eucalyptus pulp showed an evident crystalline peak (2θ close to 30°) in comparison to the treated pine pulp. This fact may have occurred due to the treatment of the eucalyptus pulp with calcium hydroxide. The same evident peak was observed by Mohamadzadeh-Saghavaz et al. [38] when analyzing patterns of composites produced with cellulose and CaCO3. The peak is typical when evaluating materials that have calcite in their composition. As previously seen, the eucalyptus nanofibrils showed carbonate crystals in the nets, which may have trapped the silver nanoparticles. Despite the higher content of celluloses in the treated pine pulps and the higher hemicelluloses content in the treated eucalyptus pulp, the crystallinity of the pine CNFs was lower.

4 Conclusion

In this study, CNFs films treated with commercial solution of Ag nanoparticles stabilized with natural tannin and silane groups were evaluated as inhibitor of Listeria monocytogenes and Salmonella enteriditis growth. Growth inhibitory halos were more expressive when the treatment with both antimicrobial solutions were done in the films produced with pine CNFs with addition of the citric acid, also highlighting its effect on the bacterium Salmonella enteriditis. The chemical analysis showed a higher content of cellulose in pine nanofibrils. The content of hemicelluloses in the treated pine pulp (11.32%) was lower in comparison to the found in the treated eucalyptus pulp (14.46%). The treated eucalyptus pulp showed higher WRI and viscosity values in relation to the treated pine pulp. The XRD diffractogram presented higher crystallinity index for the treated eucalyptus pulp (70%) with a characteristic peak of calcium carbonate. All treated films showed antimicrobial potential. Further studies should be performed in order to evaluate the inhibition of other types of bacteria.

References

Prado NRT, Raabe J, Mirmehdi S, Hugen LN, Lima LC, Ramos ALS, Guimarães Junior M, Tonoli GHD (2017) Strength improvement of hydroxypropyl methylcellulose/starch films using cellulose nanocrystals. Cerne 23:423–434

Puertas AI, Etxabide A, Dueñas MT, Guerrero P, Caba K (2018) Citric acid-incorporated fish gelatin/chitosan composite films. Food Hydrocoll 86:95–103

Azevedo VM, Dias MV, Elias HHS, Fukushima KL, Silva EK, Carneiro JDS, Soares NFF, Borges SV (2018) Effect of whey protein isolate films incorporated with montmorillonite and citric acid on the preservation of fresh-cut apples. Food Res Int 107:306–313

Bufalino L, Sena Neto AR, Tonoli GHD et al (2015) How the chemical nature of Brazilian hardwoods affects nanofibrillation of cellulose fibers and film optical quality. Cellulose 22:3657–3672

Scatolino MV, Bufalino L, Mendes LM, Guimarães Júnior M, Tonoli GHD (2017) Impact of nanofibrillation degree of eucalyptus and Amazonian hardwood sawdust on physical properties of cellulose nanofibril films. Wood Sci Technol 51:1095–1115

Scatolino MV, Fonseca CS, Gomes MS, Rompa VD, Martins MA, Tonoli GHD, Mendes LM (2018) How the surface wettability and modulus of elasticity of the Amazonian paricá nanofibrils films are affected by the chemical changes of the natural fibers. Eur J Wood Prod 76:1581–1594

Moraes ARF, Gouveia LER, Soares NFF, Santos MMS, Gonçalves MPJC (2007) Development and evaluation of antimicrobial film on butter conservation. Ciênc Tecnol Aliment 27:33–36

Tajkarimi M, Ibrahim AS (2011) Antimicrobial activity of ascorbic acid alone or in combination with lactic acid on Escherichia coli O157:H7 in laboratory medium and carrot juice. Food Control 22:801–804

Birck C, Degoutin S, Maton M, Neut C, Bria M, Moreau M, Fricoteaux F, Miri V, Bacquet M (2016) Antimicrobial citric acid/poly (vinyl alcohol) crosslinked films: effect of cyclodextrin and sodium benzoate on the antimicrobial activity. LWT Food Sci Technol 68:27–35

Dutta PK, Tripathi S, Mehrotra GK, Dutta J (2009) Perspectives for chitosanbased antimicrobial films in food applications. Food Chem 114:1173–1182

Shankar S, Rhim JW (2018) Preparation of sulfur nanoparticle-incorporated antimicrobial chitosan films. Food Hydrocoll 82:116–123

Khan MZH, Tareq FK, Hossen MA, Roki MNAM (2018) Green synthesis and characterization of silver nanoparticles using Coriandrum sativum leaf extract. J Eng Sci Technol 13:158–166

Giorgi R, Dei L, Ceccato M, Schettino C, Baglioni P (2002) Nanotechnologies for conservation of cultural heritage: paper and canvas deacidification. Langmuir 18:8198–8203

Poggi G, Giorgi R, Toccafondi N, Katzur V, Baglioni P (2010) Hydroxide nanoparticles for deacidification and concomitant inhibition of iron-gall ink corrosion of paper. Langmuir 26:19084–19090

Giorgi R, Chelazzi D, Baglioni P (2005) Nanoparticles of calcium hydroxide for wood conservation. The deacidification of the Vasa Warship. Langmuir 21:10743–10748

Bonilla J, Talón E, Atarés L, Vargas M, Chiralt A (2013) Effect of the incorporation of antioxidants on physicochemical and antioxidant properties of wheat starch–chitosan films. J Food Eng 118:271–278

Olsson E, Hedenqvist MS, Johansson C, Järnström L (2013) Influence of citric acid and curing on moisture sorption: diffusion and permeability of starch films. Carbohydr Polym 94:765–772

Coma V, Sebti I, Pardon P, Pichavant FH, Deschamps A (2003) Film properties from crosslinking of cellulosic derivatives with a polyfunctional carboxylic acid. Carbohydr Polym 51:265–271

Chabrat E, Abdillahi H, Rouilly A, Rigal L (2012) Influence of citric acid on thermoplastic wheat flour/poly (lactic acid) blends. I: thermal, mechanical and morphological properties. Ind Crop Prod 37:238–246

Shi R, Bi J, Zhang Z, Zhu A, Chen D, Zhou X, Tian W (2008) The effect of citric acid on the structural properties and cytotoxicity of the polyvinyl alcohol/starch films when molding at high temperature. Carbohydr Polym 74:763–770

Scharff RL (2012) Economic burden from health losses due to foodborne illness in the United States. J Food Prot 75:123–131. https://doi.org/10.4315/0362-028X.JFP-11-058

Burall LS, Laksanalamai P, Datta AR (2012) Listeria monocytogenes mutants with altered growth phenotypes at refrigeration temperature and high salt concentrations. Appl Environ Microbiol 78:1265–1271

Tonoli GHD, Holtman KM, Glenn G, Fonseca AS, Wood D, Williams T, Sá VA, Torres L, Klamczynski A, Orts WJ (2016) Properties of cellulose micro/nanofibers obtained from eucalyptus pulp fiber treated with anaerobic digestate and high shear mixing. Cellulose 23:1239–1256

Clinical and Laboratory Standards Institute (CLSI) (2012) Performance standards for antimicrobial disk susceptibility tests: approved standard—Eleventh edition. M02-A11

Gomide JL, Demuner BJ (1986) Determination of lignin content in woody material: modified Klason method. O Pap 47:36–38

Goldschmitd O (1971) Ultraviolet spectra. In: Sarkanen KV, Ludwig CH (eds) Lignins. Wiley-Interscience, New York, pp 241–266

Wallis AFA, Wearne RH, Wright PJ (1996) Chemical analysis of polysaccharides in plantation eucalypt woods and pulps. Appita J 49:258–262

TAPPI—Technical Association of the Pulp and Paper Industry (1994) T230—Standard methods of technical association of the pulp and paper industry. TAPPI, Atlanta

Nogueira JMR, Miguel LFS (2009) Bacteriologia. Molinaro EM, Caputo LFG, Amendoeira MRR: Conceitos e Métodos para a Formação de Profissionais em Laboratórios de Saúde, 4th edn. EPSJV, IOC, Rio de Janeiro, pp 222–397

Scampicchio M, Wang J, Blasco AJ, Arribas SA, Mannino S, Escarpa A (2006) Nanoparticle-based assays of antioxidant activity. Anal Chem 78:2060–2063

Yue YY, Liu ZX, Wan TT, Wang PC (2013) Effect of phosphate–silane pretreatment on the corrosion resistance and adhesive-bonded performance of the AZ31 magnesium alloys. Prog Org Coat 76:835–843

Wan TT, Liu ZX, Bu MZ, Wang PC (2013) Effect of Na2MoO4 on bond strength of adhesive-bonded phosphate coated magnesium AZ31 sheets. Int J Adhes Adhes 40:38–48

Ansarifar MA, Chong LK, Zhang L, Bell A, Ellis RJ (2003) Effect of bifunctional organosilane on the joint strength of some natural rubber compounds to nylon 6,6. Int J Adhes Adhes 23:177–188

Al-Rousan WM, Olaimat AN, Osaili TM, Al-Nabulsi AA, Ajo RY, Holley RA (2018) Use of acetic and citric acids to inhibit Escherichia coli O157:H7, Salmonella Typhimurium and Staphylococcus aureus in tabbouleh salad. Food Microbiol 73:61–66. https://doi.org/10.1016/j.fm.2018.01.001

Christiernin M, Henriksson G (2003) Structure of hemicelluloses Pine kraft cooking liquors. In: International symposium on wood and pulping chemistry, Sweden. Proceedings. TAPPI, Sweden

Pedrazzi C, Colodette JL, Oliveira RC, Gomide JL, Wille VKD, Coldebella R (2015) Xylans on eucalyptus brown pulp propertie. Ciência Rural 45:1585–1591

He L, Gao S, Wu H, Liao X, He Q, Shi B (2012) Antibacterial activity of silver nanoparticles stabilized on tannin-grafted collagen fiber. Mater Sci Eng C 32:1050–1056

Mohamadzadeh-Saghavaz K, Resalati H, Ghasemian A (2014) Cellulose-precipitated calcium carbonate composites and their effect on paper properties. Chem Pap 68:774–781

Acknowledgements

The authors thank to Fundação de Amparo à Pesquisa do Estado de Minas Gerais—FAPEMIG, Coordenacão de Aperfeiçoamento de Pessoa de Nível Superior—CAPES, Conselho Nacional de Desenvolvimento Científico e Tecnológico—CNPq, Brazilian Research Network in Lignocellulosic Composites and Nanocomposites—RELIGAR and TNS Nanotecnologia LTDA (Florianópolis-SC, Brazil) by donation of the antimicrobial compounds.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Scatolino, M.V., Dias, M.C., Silva, D.W. et al. Tannin-stabilized silver nanoparticles and citric acid added associated to cellulose nanofibrils: effect on film antimicrobial properties. SN Appl. Sci. 1, 1243 (2019). https://doi.org/10.1007/s42452-019-1289-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-019-1289-3