Abstract

Phosphorylated adsorbent is commonly used in the extraction of rare earth metals and radioactive waste because of its high affinity in acidic condition. In this study, adsorbent containing phosphoric acid groups was synthesized by one-step radiation-induced grafting of 2-hydroxyl methacrylate phosphoric acid monomer (2-HMPA) onto kenaf fibers. The kenaf fibers were pre-treated with sodium chlorite prior grafting process. The incorporation of poly (2-HMPA) in the bleached kenaf fibers was confirmed by Fourier transform infrared spectroscopy (FTIR), FT-IR chemical imaging and scanning electron microscopy (SEM). The structural property was investigated using X-ray diffraction (XRD). The result revealed optimum grafting yield of 91.3% with 10% 2-HMPA and 50 kGy at 40 °C for 3 h. The performance of the synthesized adsorbent showed almost complete thorium adsorption. The removal efficiency of 99.9% thorium from aqueous solution was achieved using fibrous adsorbent at an initial thorium concentration of 10 mg/L, a reaction time of 3 h, and pH of 3 at room temperature. This single step combining grafting and functionalization to modify kenaf fibers showed sufficient property for application of natural fibers as adsorbent.

Similar content being viewed by others

1 Introduction

Natural fiber is known as green material ecologically that are abundantly found and widely used around the world. Particularly, kenaf (Hibiscus cannabinus L.) is a renewable plant-based bio-fiber with low plantation cost, short period of maturity, nontoxicity and biodegradability [1,2,3,4]. This plant can be cultivated easily and grows well in the tropical regions including Peninsula Malaysia [5]. The kenaf fiber has been used for various products, such as textiles, paperboard, rope, paper and reinforcing fiber in polymer composites [6,7,8]. Significant efforts have been done to further improve and impart new properties onto the kenaf fibers by various modification techniques. One of the most established techniques is graft modification designed to introduce new chemical and physical properties into the natural polymer substrates [9]. Radiation grafting gives special advantanges over the conventional grafting technique and is found to be a versatile method and capable to graft moiety on the surface and bulk of the substrates [10]. However, as shown in Table 1, kenaf bast fiber consists of 15 – 19% lignin. Lignin is a good scavenger of radicals, where aromatic groups in the lignin reduce the efficiency of radical formation and it is required to be removed prior to radiation graft polymerization.

Removal of hazardous metal ions and radioactive elements from the waste waters have gained increasing attention due to the adverse effects of these pollutants to all living organisms. Various methods have been reported for the removal of thorium form solution, including chemical precipitation [12], solvent extraction [13] and adsorption [14]. Among all the treatment methods, adsorption is the most effective method for separation and decontamination of thorium from polluted water [9]. Typically, the concentration of thorium in waste water is far below the value that is suitable for separation using solvent extraction and chemical separation, but can be removed effectively by adsorption technique. In addition, more efforts are placed towards improving adsorption technique because of its good operational flexibility, high efficiency, and excellent reusability.

Adsorbents developed using the naturally occuring based materials have gained increasing attention as they are abundant resources that offer cheap and facile modification to impart desired functional groups for specific binding property of the synthesized adsorbent for removal of pollutants from waste water. The kenaf fiber has been utilized as an adsorbent for removal of various pollutants in water such as copper [15], nickel [16], lead, zinc [5], oil removal [17], dye [18] and fluoride [19]. However, it has not been investigated for removal of thorium from solution.

The most common method reported on the preparation of radiation grafted adsorbent for removal of metal ions in solution involves two steps, which are graft polymerization followed by chemical modification with desired moiety groups [9]. However, single step modification offers better economy over two-step modification with less consumption of chemicals, time and advantage for up-scaling or industrial production.

In this study, a one-step grafting technique was introduced to synthesize phosphorylated adsorbent by radiation-induced graft polymerization of 2-hydroxyl methacrylate phosphoric acid monomer (2-HMPA) onto kenaf fiber. The effect of grafting parameters to achieve optimum grafting yield was evaluated. The morphology, structure and chemical properties of the synthesized kenaf adsorbent with reference to the original fiber were evaluated. The prepared kenaf adsorbent was tested for thorium adsorption ability in a batch adsorption experiments mode.

2 Experimental

2.1 Materials

Kenaf fibers used in this study were supplied by Kenaf Bio Solution Sdn Bhd. Sodium chlorite, Isopropanol and Tween20 were purchased from Sigma Aldrich. 2-hydroxyl methacrylic phosphoric acid monomer (2-HMPA) was supplied by Kyoeisha Chemical. The chemical structure of 2-HMPA is shown in Fig. 1. All the chemicals in this research were of analytical grade and used as received without going through any purification.

2.2 Pre-treatment of kenaf fibers

The pre-treatment was done according to the method in our previous study [20]. The pH of the sodium chlorite (NaClO2) solution of 0.7% was adjusted to 4 and the dried kenaf bast fibers were treated with sodium chlorite solution at 70 °C for 6 h under continuous stirring. Then, the kenaf fibers were drained and washed with distilled water and dried in an oven at 60 °C for 12 h. The lignin content of treated and raw kenaf fiber were determined according to TAPPI T222 om-02 Standard Method for determination of acid-insoluble lignin in wood and pulp.

2.3 Radiation grafting of 2-HMPA onto kenaf fibers

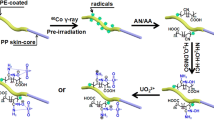

Kenaf fiber mainly consists of cellulose, hemicellulose and lignin. The aromatic compounds in lignin reduced the efficiency of radical formation and subsequently limit the grafting yield. Therefore, kenaf fibers used as substrate for radiation grafting need to be pre-treated to remove lignin [9]. Ghosh et al. reported that radiation can change phenol into quinone structures, which hinders the graft copolymerization to occur and eventually enchanced the homopolymer formation [21]. One-step radiation grafting of 2-HMPA onto kenaf fibers was done by radiation-induced graft copolymerization as shown in Fig. 2. Treated kenaf fibers were placed in a sealed zipper bag purged with N2 gas to remove the trapped air prior to irradiation on a dry ice using EPS 3000 electron beam accelerator (10 mA of current and 2 MeV voltage). Irradiation dose was fixed at 50 kGy and 100 kGy. The concentrations of 2-HMPA concentration were varied at 0.5, 3, 5 and 10% in water with the presence of Tween20 as surfactant. The monomer-solution was emulsified with high speed homogenizer and purged with N2 gas. The emulsified grafting solution was transferred into a vacuumed glass ampoules in which the irradiated fibers were kept and the glass ampoule was placed in a water bath at 40 °C for 1, 2, 3, 4 and 5 h. Finally, the grafted kenaf fibers were washed thoroughly using isopropanol and dried in an oven. The grafting yield (%) was calculated based on Eq. (1) as shown below.

where Wi and Wf represent weight gain percentage of kenaf fibers before and after grafting process.

2.4 Characterization

The 2-HMPA grafted fibers were analysed with Fourier transformed infrared (FTIR) imaging system analysis performed on a Cary 620 spectrometer (Agilent) in ATR mode. The FTIR spectra was recorded in the range from 600 to 4000 cm−1, with a resolution of 4 cm−1 and averaged over 32 scans. Morphological analysis of the 2-HMPA grafted fibres was performed with scanning electron microscopy (SEM) using Hitachi-SU350 at the voltage of 15.0 kV and at a current of 0.2 mA. Elemental identification was performed using an energy dispersive X-ray analyzer (EDX). BioRad coating system was used to sputter gold onto the samples under vacuum condition. Ungrafted fibers and 2-HMPA grafted fibers with yield of 98% were analyzed to observe the morphological changes resulting from radiation grafting process. Thermal gravimetric analysis was carried out using thermogravimetry analyzer Perkin Elmer Pyris 1 to study the thermal stability of the grafted kenaf fiber. About 4 mg of sample was weighed into alumina crucible and the thermogram was recorded from 25 to 600 °C at a heating rate 10 °C/min under 20 ml/min nitrogen flow. The crystallinity index was measured via x-ray diffractometer (XRD) using Segal’s empirical method [22] and was calculated using empirical method (peak height method) as shown in Eq. (2), focusing on the influence of fluctuations in the primary radiation.

where Ia and I0 represent heights of the amorphous and total intensity, respectively.

2.5 Adsorption of thorium using kenaf fibers

Batch type adsorption test was done unit using thorium standard stock solution. About 10 mg of grafted kenaf fibers (adsorbent) were immersed in 50 mL solution of 10 mg/L initial concentration of thorium. After continuous stirring at various time (15 min to 180 min), the sample was filtered and the final concentration of thorium in the solution was measured using a NexION 350× inductive coupled plasma mass spectrometry (ICP-MS) system (Perkin Elmer, UK). The removal percentage of thorium was studied using pH 3. The pH of the solution was adjusted using nitric acid 1 M and sodium hydroxide 1 M. The removal (%) of thorium by grafted kenaf adsorbent was calculated by Eq. (3).

where Ci and Cf are the initial and residual concentration of thorium in the solution.

3 Results and discussion

3.1 Effect of reaction time and monomer concentration on grafting yield

Treated kenaf fibers with lignin content of 3.3% were used as trunk polymer. Complete data of lignin content were given in Supplementary Information. The 2-HMPA concentration selected for this study was 0.5, 3, 5 and 10%. The reaction time was varied from 0.5 to 5 h, with 40 °C reaction temperature and 50 kGy irradiation dose. The results obtained were illustrated in Fig. 3. Notably, the grafting yield increases with the monomer concentration. Drastic increase in grafting yield can be observed from 5 to 10% of 2-HMPA. However, the grafting yield showed insignificant reduction after 3 h. At 3 h of reaction time, the grafting yield at 0.5% of 2-HMPA was about 39.0% and it increased to 91.3% at 10% 2-HMPA. The grafting yield reduced to 87.7% at 10% 2-HMPA after 3 h. The study can conclude that the grafting yield increases with concentration of monomer but only up to a certain extent and thereafter, the grafting yields show some insignificant reduction. Due to the existence of additional monomers, the active radical sites formed on polymer backbone were able to have more interaction with monomers, which instantly yields higher grafting. Insignificant changes in grafting yield at higher concentration may be due to exhaustion of free radicals on the polymer matrix. Under this circumstance, any increase in grafting yield can only be expected with an increase in irradiation dose, which will generate more radicals on the trunk polymer [23]. The increase in reaction time could raise the interaction between 2-HMPA and the free radicals on polymer trunk which will cause the mobility of monomer molecules and their collision with polymer backbone. This interaction sustains bonding between monomer and polymer backbone. The propagation of grafting chains took place due to availability of more active species and sufficient time. The marginal increase in degree of grafting versus time was also reported by Sharif et al. [20]. Conclusively, the results reveal that the grafting yields in the present study are depended on monomer concentration and reaction time.

3.2 Evaluation of 2-HMPA radiation-grafted kenaf fibers properties

The succesful incorporation of 2-HMPA by radiation-induced graft polymerization onto kenaf fibers were confirmed by FTIR and EDX. The ungrafted kenaf fiber and 2-HMPA grafted fibers were analysed with FTIR-ATR technique at a frequency range of 4000 cm−1 to 600 cm−1 with chemical imaging using FPA detector. FPA chemical imaging provides rapid high spatial resolution chemical distribution, where it gives spatial and spectral information simultaneously at targeted stretching vibration. Figure 4 illustrates the spectrum obtained from the instrument for both ungrafted and 2-HMPA grafted fibers. The common stretching of lignocellulosic fibers such as O–H stretching at 3340 cm−1, C–H stretching at 2913 cm−1, C=C at 1632 cm−1, C–O stretching of cellulose at 1016 cm−1 were observed in both ungrafted and grafted fibers. Meanwhile, the detection of peaks at 1732 cm−1 and 1140 cm−1 were assigned for C=O and C–O stretching vibration representing the –COO– ester group of 2-HMPA. As seen in Fig. 5, the coloured images represents chemical image at 1732 cm−1 which corresponds to C=O groups of 2-HMPA. The image attained shows localized high density of carbonyl group, thus the incorporation of 2-HMPA onto kenaf fiber is evidentally proven. The vibration at 1150–1032 and 960 cm−1 were assigned for PO43−. This indicates successful incorporation of 2-HMPA onto kenaf fibers. This observation was in agreement with Hayashi et al. on grafting of phosphoric monomer onto PE/PP fibers [24]. On top of it, the peak intensity of the cellulose and hemicellulose region at the bands of 3340 cm−1, 2913 cm−1 and 1016 cm−1 were extremely reduced resulting from grafting of monomer onto the fibers. This could be possibly due to the consumption of most -OH sites found on the polymer backbone by 2-HMPA molecules. The formation of poly(2-HMPA) chains, which elongate from the trunk polymer, cover the entire fiber at higher grafting yield, thus making the detection of C-H and C-O bands on grafted fibers more difficult.

Energy Dispersive X-ray (EDX) analysis was performed on treated kenaf fiber and grafted kenaf fiber. As shown in Fig. 6, EDX spectra obtained from treated kenaf fiber confirms the presence of chlorine in the fiber due to the usage of NaClO2 during the pre-treatment of the raw kenaf fibers. Meanwhile for grafted kenaf fiber, all three non-hydrogen elements which compose the copolymer of 2-HMPA grafted onto the fiber (carbon, oxygen and phosphorus) were detected.

Significant morphological changes can be seen through SEM observation in Fig. 7. For raw kenaf fiber, individual single fibers were linked and bundled together by lignin composing fiber bundles as shown in Fig. 7a. The surface layer exhibited coarse morphology where it is clearly shown that the fibres were coated with surface impurities, probably waxy substances of lignin and hemicellulose. Kenaf fibers that were treated using NaClO2 show individual single fiber with clear and smooth surface, which indicates the removal of surface components, mainly lignin and hemicellulose from the raw fiber (Fig. 7b). Thick polymer coating was observed on the surface of the grafted fiber. The cross section image of the grafted fiber also revealed the polymerization of 2-HMPA layer inside the fiber’s hollow core.

The intensity of the amorphous scatter at 2θ = 22° was measured as shown in Fig. 8 and calculation of the crystallinity index (%) was performed using Segal’s empirical method. It is evident from the XRD results in Table 2 that the incorporation of the monomer chains onto the back-bone caused reduction in the crystallinity index. Raw kenaf fiber shows the highest percentage of crystallinity index as compared to the grafted kenaf fiber. This suggests that the reduction in overall crystallinity of the grafted fibers are attributed to the substitution of the crystalline composition with the amorphous grafted monomer.

Figure 9 summarizes the comparison of thermograph for raw kenaf fiber, treated kenaf fiber and grafted kenaf fiber. All samples exhibited initial weight loss from 30 to 115 °C due to evaporation of absorbed water. Weight losses were observed from 200 to 350 °C, corresponding to the volatilization of organic compound and decomposition of cellulose and hemicellulose. This is in accordance with Luo et al. [25] where they observed the same temperature range for decomposition of water hyacinth fibre. In comparison to treated kenaf fibre, greater weight loss was found at the same temperature range for the grafted kenaf fibre. The copolymer has ester and phosphates groups which result in two decompositions as shown in the figure for the grafted kenaf. According to Choi et al. [26], the decomposition of 2,3-epoxy-propanol, particularly for the carboxylate ester group, can be observed at the temperature range from 220 to 300 °C. Meanwhile, Kiran et al. [27] evaluated early thermal decomposition of triphosphate esters at 350 °C, with the least amount of residue at 800 °C. Therefore, increasing in weight loss can be attributed to the ester group of 2-HMPA grafted on the kenaf fiber backbone. A shift in the degradation temperature to higher temperature was observed after graft copolymerization. This proved that graft copolymerization had increased the thermal stability of kenaf fiber. Final weight loss at around 500 °C was due to lignin. Lignin was more stable and decompose at higher temperature. This thermal behaviour of natural fiber has been well-explained by several researchers [7,8,9].

3.3 Adsorption of thorium using 2-HMPA radiation-grafted kenaf fibers

The 2-HMPA modified fibrous adsorbent consists of –HPO4 and –H2PO4 groups which can form stable complexes with thorium ions. Another possible adorption mechanism involves the complexation of thorium ions with hydroxide groups incorporated on the surface of grafted fibers. To study the effect of time on adsorption of thorium ion onto the newly prepared fibrous adsorbent containing –PO4 groups, the adsorption was studied by batch mode. Figure 10 shows the removal (%) of thorium from solution as a function of time and thorium removal increases with the increasing reaction time gradually in the initial 45 min. Then, removal of thoirum increases rapidly at reaction time from 60 to 150 min beyond which it starts to level off and achieives equlibrium with > 99% at 150 min. The slow adsorption behaviour before the first 60 min was due to the grafted kenaf swelling factor during the process. The sites become available gradually as the grafted kenaf swells. After 60 min, the grafted kenaf is in the swollen state, where the sites are highly available for adsorption resulting in significant uptake of thorium ions until it reached its full adsorption after 180 min where more than 99.9% of thorium ions was removed. The accessible area of the fiber was one of the most important factors that shape the rate and extent of adsorption [28]. Therefore, it can be concluded that an increase in contact time provides further opportunity for the adsorbent and adsorbate to react, resulting in higher uptake capacity. This similar trend results in contact time dependency of metal ions adsorption reported by Kehinde et al. using two adsorbents, coconut husk and teak tree bark [29].

4 Conclusion

2-hydroxyl methacrylate phosphoric acid (2-HMPA) grafted kenaf fiber has been successfully synthesized by electron beam irradiation by single step grafting. Factors affecting the grafting reaction, i.e. reaction time and monomer concentration were investigated. Based on the overall findings, the grafting of 2-HMPA onto kenaf fibers strongly dependent on 2-HMPA monomer concentration and reaction time. The morphology of ungrafted and grafted fiber was characterized by SEM. The incorporation of 2-HMPA was also confirmed by FTIR and EDX. XRD spectra showed that grafting process has decreased the crystallinity index of kenaf fiber. The grafted kenaf fiber suceesfully removed 99.9% of thorium ions after 180 min of adsorption reaction.

5 Supplementary information

See supplementary information for the complete data of lignin content (Table S1) and thorium uptake capacities (Table S2).

References

Satya P, Karan M, Kar C, Mahapatra A, Mahapatra B (2013) Assessment of molecular diversity and evolutionary relationship of kenaf (Hibiscus cannabinus L.), roselle (H. sabdariffa L.) and their wild relatives. Plant Syst Evol 299:619

Monteiro SN, Lopes FPD, Ferreira AS, Nascimento DCO (2009) J Miner Metals Mater Soc (JOM) 61: 17

Nishino T, Hirao K, Kotera M, Nakamae K, Inagaki H (2003) Kenaf reinforced biodegradable composite. Compos Sci Technol 63:1281

Mohanty AK, Misra M, Drzal LT (2005) Natural fibers, biopolymers, and biocomposites. CRC Press, Boca Raton

Shamsudin R, Abdullah H, Kamari A (2016) Application of Kenaf Bast fiber to adsorb Cu (II), Pb (II) and Zn (II) in aqueous solution: single-and multi-metal systems. Int J Environ Sci Develop 7:715

Lee SA, Eiteman MA (2001) Ground kenaf core as a filtration aid. Ind Crops Prod 13:155

Ramaswamy GN, Sellers T, Tao W, Crook G (2003) Kenaf nonwovens as substrates for laminations. Ind Crops Prod 17:1

Edeerozey AMM, Akil HM, Azhar AB, Ariffin MIZ (2007) Chemical modification of kenaf fibers. Mater Lett 61:2023

Wojnárovits L, Földváry CM, Takács E (2010) Radiation-induced grafting of cellulose for adsorption of hazardous water pollutants: a review. Radiat Phys Chem 79:848

Nasef MM, Ting TM, Abbasi A, Layeghi-moghaddam A, Alinezhad SS, Hashim K (2016) Radiation grafted adsorbents for newly emerging environmental applications. Radiat Phys Chem 118:55

Khalil HA, Yusra AI, Bhat AH, Jawaid M (2010) Cell wall ultrastructure, anatomy, lignin distribution, and chemical composition of Malaysian cultivated kenaf fiber. Ind Crops Prod 31(1):113–121

Zhu Z, Pranolo Y, Cheng CY (2015) Separation of uranium and thorium from rare earths for rare earth production—a review. Miner Eng 77:185

Sharma J, Ruhela R, Harindaran K, Mishra S, Tangri S, Suri A (2008) Separation studies of uranium and thorium using tetra (2-ethylhexyl) diglycolamide (TEHDGA) as an extractant. J Radioanal Nucl Chem 278:173

Aydin FA, Soylak M (2007) Solid phase extraction and preconcentration of uranium (VI) and thorium (IV) on Duolite XAD761 prior to their inductively coupled plasma mass spectrometric determination. Talanta 72:187

Sajab MS, Chia C-H, Zakaria S, Jani SM, Khiew PS, Chiu WS (2010) Removal of copper (II) ions from aqueous solution using alkali-treated kenaf core fibres. Adsorpt Sci Technol 28:377

Florence JAK, Gomathi T, Thenmozhi N, Sudha PN (2015) Adsorption study: re-moval of nickel ions using Kenaf fiber/chitosan biosorbent. J Chem Pharm Res 7:410

Chol HM, Rinn MC (1992) Environ Sci Technol 26:772

Mahmoud DK, Salleh MAM, Karim WAWA, Idris A, Abidin ZZ (2012) Batch adsorption of basic dye using acid treated kenaf fibre char: equilibrium, kinetic and thermodynamic studies. Chem Eng J 181–182:449

Yusof SRM, Zahri NAM, Koay YS, Nourouzi MM, Chuah LA, Choong TSY (2015) Removal of fluoride using modified kenaf as adsorbent. J Eng Sci Technol 10:11

Sharif J, Mohamad SF, Othman NAF, Bakaruddin NA, Osman HN, Güven O (2013) Graft copolymerization of glycidyl methacrylate onto delignified kenaf fibers through pre-irradiation technique. Radiat Phys Chem 91:125

Ghosh P, Ganguly PK, Bhaduri SK (1994) Graft copolymerization of acrylonitrile on jute using aqueous Cu2−-IO4 combination as initiator: Some key points and mechanism. Eur Polym J 30:749

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Textile Res J 29:786

Goel N, Kumar V, Rao M, Bhardwaj Y, Sabharwal S (2011) Functionalization of cotton fabrics by radiation induced grafting of quaternary salt to impart antibacterial property. Radiat Phys Chem 80:1233

Hayashi N, Hoshina H, Amada H, Yamanobe T, Seko N (2014) Evaluation of the scandium affinity under the iron coexistence using radiation grafted adsorbents. 日本イオン交換学会誌 25:105

Luo GE, Strong PJ, Wang H, Ni W, Shi W (2011) Radiolytic immobilization of lipase on poly (glycidyl methacrylate)-grafted polyethylene microbeads. Biores Technol 102:6990

Choi S-H, Lee K-P, Kang H-D, Park HG (2004) Radiolytic immobilization of lipase on poly (glycidyl methacrylate)-grafted polyethylene microbeads. Macromol Res 12:586

Kiran YB, Devendranath Reddy C, Gunasekar D, Naga Raju C, Barbosa LCA, Marney DCO, Russell LJ (2007) Synthesis and TGA evaluation of novel triphosphate esters. J Fire Sci 25(3):193–215

Kargarzadeh H, Ahmad I, Abdullah I, Dufresne A, Zainudin SY, Sheltami RM (2012) Effects of hydrolysis conditions on the morphology, crystallinity, and thermal stability of cellulose nanocrystals extracted from kenaf bast fibers. Cellulose 19:855

Kehinde OO, Oluwatoyin TA, Aderonke OO (2009) Comparative analysis of the efficiencies of two low cost adsorbents in the removal of Cr (VI) and Ni (II) from aqueous solution. Afr J Environ Sci Technol 3:10

Mohamed NH, Ueki Y, Seko N (2013) Effect of partial delignification of kenaf bast fibers for radiation graft copolymerization. J Appl Polym Sci 127:2891

Acknowledgements

This work was financially supported by Malaysian Nuclear Agency, Ministry of Energy, Science, Technology, Environment and Climate Change (MESTECC) (FP0214D052(DSTIN)) received by N. A. F Othman. The corresponding author also would like to thank Universiti Teknologi Malaysia for providing additional financial and consultation support under Research University Grant (Q.J130000.2546.16H46) awarded to A.K Zulhairun.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No potential conflict of interest was reported by the authors relevant to this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Othman, N.A.F., Selambakkannu, S., Ting, T.M. et al. Modification of kenaf fibers by single step radiation functionalization of 2-hydroxyl methacrylate phosphoric acid (2-HMPA). SN Appl. Sci. 1, 220 (2019). https://doi.org/10.1007/s42452-019-0231-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-019-0231-z