Abstract

Purpose

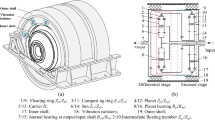

This study aims to take the compound planetary gear train as an example to investigate how the vibration isolator affects the dynamic characteristics of the gear system.

Methods

The dynamic parameters are obtained from the finite element model of the gearbox case with the vibration isolators by the substructure method. The lumped mass method is used to construct the systematic coupled dynamic model of the compound planetary gear train with the marine twin-layer gearbox case. The dynamic response of the coupled system is calculated by the numerical calculation method of the Fourier series.

Results

The number of vibration isolators negatively affects the bearing forces of the input shaft, output shaft, and planets. The influence of the number of vibration isolators on LSCs is different in the differential stage and the encased stage. When the vibration isolators stiffness is less than 200 N/μm, the stiffness of the vibration isolator has a significant effect on the bearing forces of the input shaft, output shaft, and planets. The increase in the stiffness of the vibration isolator would increase the LSCs of the differential stage and decrease the LSCs of the encased stage.

Conclusions

The number and stiffness of the vibration isolator have influences on the bearing forces and the LSCs. Compared with the LSCs in the differential stage, the LSCs in the encased stage are more sensitive to the number and stiffness of vibration isolators.

Similar content being viewed by others

Data Availability

The data used to support the findings of this study are available from the corresponding author upon request.

References

Chen P, Wei Q, Liu Z et al (2019) The influence of piping arrangement on the response of vibration isolation system under underwater explosion loading. In: Proceedings of the ASME 2019 38th international conference on ocean, offshore and arctic engineering, Glasgow, Scotland, UK. https://doi.org/10.1115/OMAE2019-95603

Luan J, Zhang J, Wan X (2019) Study on support stiffness optimization of the vibration-isolating double layer box for planetary gear reducer. J Eng Therm Energy Power 34:103–112. https://doi.org/10.16146/j.cnki.rndlgc.2019.01.018

Zhou J, Liu G, Ma S (2014) Vibration and noise analysis of two-stage marine planetary reducer. J Ship Mech 82:59–71. https://doi.org/10.3969/j.issn.1007-7294.2014.h1.025

Cui L, Huang J, Zhai H et al (2016) Research on the meshing stiffness and vibration response of fault gears under an angle-changing crack based on the universal equation of gear profile. Mech Mach Theory 105:554–567. https://doi.org/10.1016/j.mechmachtheory.2016.07.022

Iglesias M, Fernandez A, Dejuan A et al (2017) Planetary transmission load sharing: manufacturing errors and system configuration study. Mech Mach Theory 111:21–38. https://doi.org/10.1016/j.mechmachtheory.2016.12.010

Leque N, Kahraman A (2016) A three-dimensional load sharing model of planetary gear sets having manufacturing errors. J Mech Des. https://doi.org/10.1115/DETC2015-47470

Mo S, Zhang T, Jin G et al (2020) Analytical investigation on load sharing characteristics of herringbone planetary gear train with flexible support and floating sun gear. Mech Mach Theory 144:103670. https://doi.org/10.1016/j.mechmachtheory.2019.103670

Guo Y, Keller J, Parker RG (2014) Nonlinear dynamics and stability of wind turbine planetary gear sets under gravity effects. Eur J Mech A Solid 47:45–57. https://doi.org/10.1016/j.euromechsol.2014.02.013

Mo S, Zhang Y, Wu Q et al (2016) Load sharing behavior analysis method of wind turbine gearbox in consideration of multiple-errors. Renew Energ 97:481–491. https://doi.org/10.1016/j.renene.2016.05.058

Zhang D, Zhu R, Fu B et al (2019) Modal properties of contra-rotating encased differential gear train used in coaxial helicopter. J Vib Eng Technol. https://doi.org/10.1007/s42417-019-00179-0

Lin T, Xie D, Peng Q et al (2019) Joint parameter identification, vibration and noise analysis of gearbox. J Vibroeng 21:776–791. https://doi.org/10.21595/jve.2018.19779

Guo Y, Eritenel T, Ericson TM et al (2014) Vibro-acoustic propagation of gear dynamics in a gear-bearing-housing system. J Sound Vib 333:5762–5785. https://doi.org/10.1016/j.jsv.2014.05.055

Ren Y, Chang S, Liu G et al (2017) Impedance synthesis based vibration analysis of geared transmission system. Shock Vib 2017:1–14. https://doi.org/10.1155/2017/4846532

Wang J, Chang S, Wang X et al (2017) Vibration and noise analysis method of marine gear transmission including the base admittance characteristics. J Northw Polytech Univ 35:90–97 (in Chinese)

Abbes MS, Fakhfakh T, Haddar M et al (2006) Effect of transmission error on the dynamic behaviour of gearbox housing. Int J Adv Manuf Tech 34:211. https://doi.org/10.1007/s00170-006-0582-7

Zhu C, Xu X, Liu H et al (2014) Research on dynamical characteristics of wind turbine gearboxes with flexible pins. Renew Energ 68:724–732. https://doi.org/10.1016/j.renene.2014.02.047

Zhou J, Liu G, Wu L (2012) Vibration analysis of marine planetary reducer with elastic support. J Harbin Inst Technol 7:102–106+112 (in Chinese)

Wang F, Lu Y, Lee HP et al (2019) Vibration and noise attenuation performance of compounded periodic struts for helicopter gearbox system. J Sound Vib 458:407–425. https://doi.org/10.1016/j.jsv.2019.06.037

Yang LH, Wang WM, Zhao SQ et al (2014) A new nonlinear dynamic analysis method of rotor system supported by oil-film journal bearings. Appl Math Model 38:5239–5255. https://doi.org/10.1016/j.apm.2014.04.024

Guo Y, Parker RG (2011) Analytical determination of mesh phase relations in general compound planetary gears. Mech Mach Theory 46:1869–1887. https://doi.org/10.1016/j.mechmachtheory.2011.07.010

Chen Y, Zhu R, Jin G et al (2019) A new mathematical modeling method for four-stage helicopter main gearbox and dynamic response optimization. Complexity 2019:1–13. https://doi.org/10.1155/2019/5274712

Zhu Z, Zhu R, Li Y et al (2012) Impact of installation error on dynamics load sharing characteristic for encased differential herringbone train. Chin J Mech Eng-en 48:16–24. https://doi.org/10.3901/JME.2012.03.016

Acknowledgements

This work was supported by the National Key R&D Program of China (Grant no. 2018YFB2001500) and the National Natural Science Foundation of China (Grant no. 51775265).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest regarding the publication of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Rights and permissions

About this article

Cite this article

Yang, J., Yang, L., Zhu, R. et al. Effects of Vibration Isolator on Compound Planetary Gear Train with Marine Twin-Layer Gearbox Case: a Dynamic Load Analysis. J. Vib. Eng. Technol. 9, 767–780 (2021). https://doi.org/10.1007/s42417-020-00261-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42417-020-00261-y