Abstract

Purpose

Flexible couplings are widely used for accommodating various imprecisions such as misalignments and torque fluctuations in a diesel generator set. However, excessive vibration due to common engine misfires can cause premature failures in both the couplings and the whole generator set. Moreover, the coupling also affects detection performance and the occurrences of early misfires due to such faults in fuel injections and cylinder seals. In this paper, the torsional vibration along with the dynamic torque of the flexible coupling connecting a 6-cylinder diesel engine to a dynamometer is studied theoretically and experimentally.

Methods

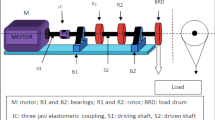

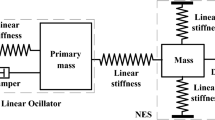

This system represents a common diesel generator set which is modeled into a torsional dynamic system with 10-degree of freedom (DOF) by the Lagrange equation method. After a verification of the model by the measurement of vibration responses at the free end and the coupling with a magnetic speed sensor and a wireless torque sensor, it is then used to predict the influences of different misfire conditions on the dynamic torque on the coupling, which helps in determining reliable diagnostic features for misfire detection and diagnosis.

Results and Conclusions

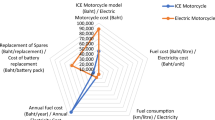

Results show that the misfires of the diesel engine have significant influences (more than 5 times higher) on the torsional vibration and load of the flexible coupling than on the dynamic torque. Nevertheless, both the torsional vibration and torque of the flexible coupling can be used to detect the occurrence of the diesel engine misfires and the vibration provides slight better results in terms of localizing the misfired cylinders.

Similar content being viewed by others

References

Ma J, Han P (2005) Influence of nonlinear stiffness of flexible coupling on torsional vibration. J Vib Shock 24:6–13

Ma J, Yang W (2006) Influence of nonlinear damping of flexible coupling on torsional vibration reduction. J Vib Shock 25:11–17

Metallidis P, Natsiavas S (2003) Linear and nonlinear dynamics of reciprocating engines. Int J Non Linear Mech 38:723–738

Huang Y, Yang S, Zhang F, Zhao C, Ling Q, Wang H (2012) Non-linear torsional vibration characteristics of an internal combustion engine crankshaft assembly. Chin J Mech Eng 25:797–808. https://doi.org/10.3901/cjme.2012.04.797

Pasricha MS, Carnegie WD (1976) Effect of the variable inertia on the damped torsional vibrations of diesel engine system. J Sound Vib 46:339–345

Brusa E, Delprete C, Genta G (1997) Torsional vibration of crankshafts: effects of non-constant moments of inertia. J Sound Vib 205:135–150

Merkisz-Guranowska A, Waligórski M (2018) Recognition and separation technique of fault sources in off-road diesel engine based on vibroacoustic signal. J Vib Eng Technol. https://doi.org/10.1007/s42417-018-0045-0

Geveci M, Osburn AW, Franchek MA (2005) An investigation of crankshaft oscillations for cylinder health diagnostics. Mech Syst Signal Process 19:1107–1134. https://doi.org/10.1016/j.ymssp.2004.06.009

Zhixiong L, Zhiwei G, Chongqing H, Aihua L (2017) On-line indicated torque estimation for internal combustion engines using discrete observer. Comput Electr Eng 60:100–115. https://doi.org/10.1016/j.compeleceng.2017.01.002

Chen J, Bond Randall R (2015) Improved automated diagnosis of misfire in internal combustion engines based on simulation models. Mech Syst Signal Process 64–65:58–83. https://doi.org/10.1016/j.ymssp.2015.02.027

Charles P, Sinha JK, Gu F, Lidstone L, Ball AD (2009) Detecting the crankshaft torsional vibration of diesel engines for combustion related diagnosis. J Sound Vib 321:1171–1185. https://doi.org/10.1016/j.jsv.2008.10.024

Acknowledgements

This work is supported by the Natural Science Foundation of China through the Grants (51575378 and 11332008).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared that they have no conflicts of interest to this work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, Z., Wu, K., Ding, Q. et al. Engine Misfire Diagnosis Based on the Torsional Vibration of the Flexible Coupling in a Diesel Generator Set: Simulation and Experiment. J. Vib. Eng. Technol. 8, 163–178 (2020). https://doi.org/10.1007/s42417-019-00097-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42417-019-00097-1