Abstract

Purpose

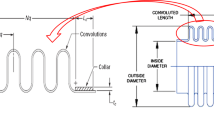

Metal expansion bellows is an important flexible element used to absorb extension or shrinkage and vibrations of the piping system used in various process applications. Failure of the bellows occurs due to the unpredictable behavior in its convolutions due to severe working conditions. Hence, determination of its dynamic characteristics is of prime importance.

Objective

To find and analyse dynamic characteristics like axial natural frequencies, modal frequency responses and mode shapes of U-shaped convolution bellows as well as the effect of increase in number of convolutions on the dynamic characteristics.

Methods

In this paper, analytical, numerical simulation and experimental investigations are performed to find the axial natural frequencies of bellows. Numerical simulation is performed using the mathematical model in MATLAB and modal analysis is performed using ANSYS 15. The deformation and axial natural frequency response of bellows with eight, nine and ten convolutions are obtained by FE analysis for various modes when bellows are subjected to different end conditions.

Results

As per the simulation and experimental modal analysis, it is seen that the range of axial natural frequencies with less number of convolutions shows maximum deformation and larger number of convolutions shows minimum deformation.

Conclusion

To decrease the axial natural frequency for the given flow rate and to avoid resonance, the number of convolutions of the bellows should be increased for designing the new configuration.

Similar content being viewed by others

References

ASME (2013) An International code 2013. ASME boiler and pressure vessel, section VIII, division-I, appendix 26 - pressure vessel and heat exchanger joints, New York, USA, pp 498–522

EJMA (2008) Standards of Expansion Joint Manufacturers Association, Inc., New York, 9th edn, section 4, pp 64–107

Shaikh H, George G, Khatak HS (2001) Failure analysis of an AM 350 steel bellows. Eng Fail Anal 8:571–576

Broman GI, Jonsson AP, Hermann MP (2000) Determining dynamic characteristics of bellows by manipulated beam finite elements of commercial software. Int J Press Vessels Pip 77:445–453

Li T (1998) Effect of the elliptic degree of Ω-shaped bellows toroid on its stresses. Int J Press Vessels Pip 75:951–954

Becht C (2000) Fatigue of bellows a new design approach. Int J Press Vessels Pip 77:843–850

Faraji GH, Mashhadi MM, Norouzifard V (2009) Evaluation of effective parameters in metal bellows forming process. J Mater Process Technol 209:3431–3437

Faraji GH, Besharati MK, Mosavi M, Kashanizadeh H (2008) Experimental and finite element analysis of parameters in manufacturing of metal bellows. Int J Manuf Technol 38:641–648

Kang BH, Lee MY, Shon SM, Moon YH (2007) Forming various shapes of tubular bellows using a single-step hydroforming process. J Mater Process Technol 194:1–6

Kang HW, Lee IH, Cho DW (2006) Development of a micro-bellows actuator using micro-stereolithography technology. Microelectron Eng 83:1201–1204

Jakubauskas V, Werner DS (1999) Transverse natural frequencies and flow induced vibrations of double bellows expansion joints. J Fluids Struct 13:461–479

Jha AK, Diwakar V, Sreekumar K (2003) Stress corrosion cracking of stainless steel bellows of satellite launch vehicle propellant tank assembly. J Eng Failure Anal 10:699–709

Lee SW (2002) Study on the forming parameters of the metal bellows. J Mater Process Technol 130–131:47–53

Wang G, Zhang KF, Wu DZ, Wang JZ, Yu YD (2006) Superplastic forming of bellows expansion joints made of titanium alloys. J Mater Process Technol 178:24–28

Zhu YZ, Wang HF, Sang ZF (2005) The effect of environmental medium on fatigue life for u-shaped bellows expansion joints. Int J Fatigue 28:1–5

Qu C, Wei H, Wang Y (2014) Analysis of Failure for mental bellows based on ANSYS. Adv Mater Res 1044–1045:910–913

Kim S, Jang B (2015) Development of Bellows design software using MATLAB. Ind J Sci Technol 8:201–206

Kim JB (2015) The effects of convolution geometry and boundary condition on the failure of bellows. Ind J Sci Technol 8:462–466

Gawande SH, Pagar ND, Wagh VB, Keste AA (2015) Numerical investigations on characteristics of stresses in U shaped metal expansion bellows. Int J Metals 1–9:2015

Gawande SH, More RR (2016) Effect of notch depth and location on modal natural frequency of cantilever beams. Structures 8:121–129

Gawande SH, Kokare DK (2018) Experimental investigations of vibration reduction in spur gear pair by method of phasing. J Vib Eng Technol 5:573–585

Li TX, Guo BL, Li TX (1990) Natural frequencies of u-shaped bellows. Int J Pressure Vessel Piping 42:61–74

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that there is no conflict of interests regarding the publication of this paper.

Rights and permissions

About this article

Cite this article

Gawande, S.H., Pagar, N.D. A Combined Numerical and Experimental Investigation on the Effect of Dynamics Characteristics of Metal Expansion Bellows. J. Vib. Eng. Technol. 6, 401–416 (2018). https://doi.org/10.1007/s42417-018-0053-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42417-018-0053-0