Abstract

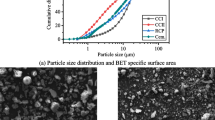

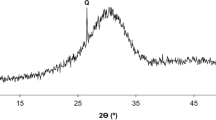

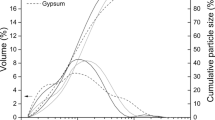

The influence of the addition of limestone at the expense of gypsum in Portland cement was investigated. Results showed that with the gradual replacement of very fine limestone instead of gypsum the hydration process improves, enhances at all curing times until 90 days. On this basis, the hydration heat, bound water, free lime contents, bulk density, compressive strength improved, were enhanced, while the apparent porosity decreased. In contrast, the water/cement ratio, both the initial, the final setting times decreased. These results were confirmed with FTIR spectra, SEM-EDAX analysis. SEM showed the formation of carboaluminate hydrates in cement pastes containing limestone, CSH, SO4−2, CO3−2, whilst the peaks of EDAX showed elements of Al+3, Fe+3, Ca+2, Al2O3.

Similar content being viewed by others

References

Bonavetti, V., Donza, H., Menéndez, G., Cabrera, O., Irassar, E.F.: Limestone filler cement in low w/c concrete: a rational use of energy. Cem. Conc. Res. 33 (2003) 865—871

Corinaldesi, V., Moriconi, G., Naik, T.R.: Characterization of marble powder for its use in mortar. Concrete, Construction, Building Mater. 24 (2010) 113—117

Demirel, B.: The effect of the using waste marble dust as fine sand on the mechanical properties of the concrete. Int. J. Phys. Sci. 5 (2010) [9], 1372—1380

Regourd, M.: Special cements with additions. Proc. 8th Congress on the Chemistry of Cements, Rio de Janeiro, Brazil 1 (1986), 119—229

El-Didamony, H., Salem, T., Gabr, N., Mohamed, T.: Limestone as a retarder, filler in limestone blended cement. Ceram.-Silik. 39 (1995) 15—19

Heikal, M., El-Didamony, H., Morsy, M.S.: Limestone-filled pozzolanic cement. Cem. Concr. Res. 30 (2000) 1827—1834

El-Didamony, H., El-Alfi, E.S.: Addition of limestone in the low heat Portland cement-Part II., Ceram.- Silik. 44 (2000) [4] 146—150.

Neville, A.M.: Properties of concrete. 5th Ed. Longman, Essex (UK), (2011) ISBN: 978-0-273-75580-7 (pbk.). http://www.pearsoned.co.uk

Hewlett, P.C.: Lea’s Chemistry of Cement, Concrete. 5th Ed., John Wiley & Sons Inc. New York, Toronto (2004), ISBN: 0470 24416 X

El-Alfi, E.S., Darweesh, H.H.M., El-Didamony, H.: Addition of limestone in the low heat Portland cement-Part I., Ceramics Silikáty, 44 (2000) [3], 109—113

Regourd, M.,: Addition of limestone in the low heat Portlant cement. Proc. 8th Int. Congr. Chem. Cem., Rio de Janeiro, 3 (1986) 199—229

Negro, A., Abbiati, G., Cussino L.: Calcium carbonate substitute in cement. Proc. 8th Int. Congr. Chem. Cem. Rio de Janiero, 3 (1986) 109—113

Tsivilis, S., Chaniotakis, E., Kakali, G., Batis, G.: An analysis of the properties of Portland limestone cements, concrete. Cem. Concr. Compo. 24 (2002) 371—378

Vernet, C., Noworyta, G.: Mechanisms of limestone reactions in the system C3A CaSO4. H2O-CH-CaCO3-H): Competition between calcium monocarbo-, monosulfo-aluminate hydrates formation. Proc. 9th Int. Congr. Chem. Cem., 4 New Delhi, India (1992) 430—436

El-Alfi, S., Radwan, A.M., Abed El-Aleem, S.: Effect of limestone fillers, silica fume pozzolana on the characteristics of sulfate resistant cement pastes. Ceram.-Silik. 48 (2004) [1] 29—33

ASTM-Standards C114-77: Standard test method for chemical analysis of hydraulic cement. (1978) 87—127

Hume, W., Madgwick, T., Moon, F., Sadek, H.: Preliminary geologic report on Gabal Tanka area. Petroleum Research Bulletin (Cairo) 4 (1920) 112—119

Youssef, M.I., Abdel Malik, W.M.: Micropaleontological zonation of the Tertiary rocks of the Tayiba-Feiran area, West-Central Sinai, Egypt. Proc. 6th Arab Science Congress, Damascus (1969) 675—684

Abul-Nasr, R.A.A., Thunell, R.C.: Eocene eustatic sea level changes, evidence from western Sinai, Egypt. Palaeogeography, Palaeoclimatology, Palaeoecology 58 (1987)1—9

Jackson, C.A.-L., Gawthorpe, R.L., Leppard, C.W., Sharp, I.R.: Rift-initiation development of normal fault blocks: insights from the Hammam Faraun fault block Suez Rift, Egypt. J. Geol. Soc. of London 163 (2006) 165—183

Abul Nasr, R.A.: Re-evaluation of the Upper Eocene rock units in West-Central Sinai. MERC Ain Shams University, Earth Science Series 4 (1990) 234—247

Refaat, A.A., Imam, M.M.: The Tayiba Red Beds: Transitional marine-continental deposits in the precursor Suez Rift, Sinai, Egypt. J. African Earth Sci. 26 (1999) [3] 467—506

Jackson, Ch.A.L.: Sedimentology and significance of an early syn-rift paleovalley, Wadi Tayiba, Suez Rift, Egypt. J. African Earth Sci. 52 (2008) 62—68

ASTM-Standards C187-86: Standard test method for normal water of consistency of hydraulic cement. (1993) 148—150

ASTM-Standards, PA, ASTM-C187-98: Standard test method for normal consistency of hydraulic cement. (2002) 163—166

ASTM Designation C191.04-: Standard test method for normal consistency, setting time of hydraulic cement, Annual Book of ASTM Standards (2008) 172—174

ASTM —Standards C191-92: Standard test method for setting time of hydraulic cement. (1993) 866—868

ASTM-Standards, PA, C191-01a: Standard test method for time of setting of hydraulic cement by Vicat needle. (2002) 180—182

ASTM-Standards, C186-92: Determination of the heat of hydration of Portland cement pastes. (1992) 162—164

Krishnaswamy, K.T., Kamasundara, A., Khandekar, A.A.: Concrete Technology, Dhanpat Rai and Sons (1983) 1—11

Kondo, R., Abo-El-Enein, S.A., Diamon, M.: Kinetics, mechanisn of hydrothermal reaction of granulated blast furnace slag. Bull. Chem. Soc. Japan 48 (1975) 222—226

Darweesh, H.H.M.: Effect of combination of Some Pozzolanic Wastes on the Properties of Portlandcement Pastes. iiC l’italiana del Cemento 808 (2005) [4] 298—310

Darweesh, H.H.M., Abo-El-Suoud, M. R.: Quaternary cement composites from industrial byproducts to avoid the environmental pollution. J. EC-Chemistry 2 (2015) [1] 78—91

Darweesh, H.H.M.: Geopolymer cements from slag, fly ash, silica fume activated with sodium hydroxide, water glass. Interceram 66 (2017) [1] 226—231

Darweesh, H.H.M.: Mortar composites based on industrial wastes. Int. J. Mater. Lifetime 3 (2017) [1] 1—8, doi: https://doi.org/10.12691/ijml-3-1-1

Darweesh, H.H.M., Youssef, H.: Preparation of 11 Å Al-substituted Tobermorite from Egyptian Trackyte Rock, its effect on the specific properties of Portland cement. Interceram 63 (2014) [7–8] 358—362

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Darweesh, H.H.M., Abou-El-Anwar, E.A. & Mekky, H.S. Addition of limestone at the expense of gypsum in Portland cement. Interceram. - Int. Ceram. Rev. 67, 18–27 (2018). https://doi.org/10.1007/s42411-018-0030-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42411-018-0030-3