Abstract

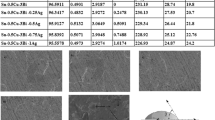

Various environment legislations lead to the ban of Pb in solder alloy making. Solder alloy is an integral part of electronic packaging industry. As a result of this researchers were searching for new combinations without lead which can replace Sn–Pb solder alloy. The new lead free solder joint should possess good mechanical properties, good wetting properties and good corrosion resistance properties. Many lead free solder alloys were discovered. Sn–0.5Cu–3Bi is a good candidate for replacing the Sn–Pb alloy with good properties. The addition of Ag into the alloy enhanced the properties, especially 1% by wt. Ag. In this paper, investigations on the corrosion behavior of Sn–0.5Cu–3Bi–xAg (x = 0, 0.5, 1% by wt.) in 3.5% NaCl is carried out using weight loss method. Microstructure and EDAX analysis were also conducted in the analysis. It is found that the corrosion rate is minimum with 1% by wt. addition of Ag. Corrosion rate is less when compared with the SAC (Sn–Ag–Cu). Sn–0.5Cu–3Bi–1Ag can be considered as a potential lead free solder joint with good corrosion resistance.

Similar content being viewed by others

References

M. Mel, Schwartz, Soldering: Understanding the Basics, 1st edn. (ASM International, West Conshohocken, 2014)

NCMS Lead-Free Solder Project Final Report, NCMS, National Center for Manufacturing Sciences, 3025 Boardwalk, Ann Arbor, Michigan 48108-3266, Report 0401RE96, August 1997

M. Mccormack, S. Jin, JEM 23, 715 (1994). https://doi.org/10.1007/BF02651364

J. Glazer, JEM 23, 693 (1994). https://doi.org/10.1007/BF02651361

Management Methods for Restriction of the Use of Hazardous Substances in Electrical and Electronic Products, http://www.chinarohs.com. Accessed 1 July 2019

J-Moss (Japanese RoHS), http://home.jeita.or.jp/eps/jmoss_en.htm. Accessed 1 July 2019

Act for Resource Recycling of Electrical and Electronic Equipment and Vehicles, http://www.rsjtechnical.com/images/Documents/Korea_RoHS_ELV_April_2007_EcoFrontier.pdf. Accessed 1 July 2019

Turkey Announces RoHS Legislation, http://www.intertek.com/news/2008/10-28-turkey-announces-rohs-legislation/. Accessed 1 July 2019

Restrictions on the Use of Certain Hazardous Substances (RoHS) in Electronic Devices, https://www.dtsc.ca.gov/HazardousWaste/RoHS.cfm. Accessed 1 July 2019

K.N. Tu, A.M. Gusak, M. Li, Physics and materials challenges for lead-free solders. J. Appl. Phys. 93, 1335–1353 (2003)

H.T. Ma, J.C. Suhling, A review of mechanical properties of lead-free solder for electronic packaging. J. Mater. Sci. 44, 1141–1158 (2009)

M. Wang, J. Wang, H. Feng, W. Ke, J. Mater. Sci. Mater. Electron. 23, 148–155 (2012)

S. Jayesh, J. Elias, Met. Mater. Int. (2019). https://doi.org/10.1007/s12540-019-00305-3

S. Jayesh, J. Elias, Experimental investigations on the effect of addition of Ag into ternary lead free solder alloy Sn–1Cu–1Ni. Lett Mater 9(2), 239–242 (2019)

S. Jayesh, J. Elias, Int J Simul Multidiscip Des Optim 10, A11 (2019). https://doi.org/10.1051/smdo/2019013

L.C. Tsao, Corrosion Resistance (In Tech, Shanghai, 2012), pp. 107–132

D.Q. Yu, W. Jillek, E. Schmitt, J. Mater. Sci. Mater. Electron. 17, 219–227 (2006)

S. Meschter, P. Snugovsky, Z. Bagheri, E. Kosiba, M. Romansky, J. Kennedy, L. Snugovsky, JOM J. Min. Met. Mat. S 66, 2320–2333 (2014)

W. Lawson, The effects of design and environmental factors on the reliability of electronic products. Ph.D. Thesis, Salford University (2007)

Dezhi Li, Paul P. Conway, Changqing Liu, Corros. Sci. 50, 995–1004 (2008)

C.W. See et al., Corrosion behavior of corroded Sn–3.0Ag–0.5Cu solder alloy. Procedia Chem 19, 847–854 (2016). https://doi.org/10.1016/j.proche.2016.03.112

R. Baboian, Corrosion Tests and Standards: Application and Interpretation, 2nd edn. (ASTM International, West Conshohocken, 2005). https://doi.org/10.1520/MNL20-2ND-EB

Acknowledgements

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jayesh, S., Elias, J. Investigations on the Corrosion Properties of Sn–0.5Cu–Bi–xAg Lead Free Solder Alloys in 3.5% NaCl Solution. Trans. Electr. Electron. Mater. 22, 150–159 (2021). https://doi.org/10.1007/s42341-020-00219-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42341-020-00219-7