Abstract

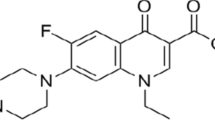

The choice of the functional monomer is addressed in the present study. It is not only dictated by its ability to interact with the template molecule. Its reactivity towards the cross-linker in the radical polymerization reaction is also to be considered in order to yield a suitable distribution of the monomer bearing binding groups within the material and also to adjust the cross-linking degree which provides rigidity to MIP network. MIPs prepared using two functional monomers of very different reactivity in radical polymerization allowed to investigate the criteria for the optimum choice of the functional monomer. MIPs were made of cross-linked poly(methacrylic acid) or poly(maleic acid) bound as thin films to a silica solid support. Ethylene glycol dimethacrylate was the cross-linker. Calculations of the composition drift of the copolymer material from monomers reactivity ratios give new insights into the control of MIP properties by the choice of the functional monomer. As a consequence of the lower reactivity of maleic acid than methacrylic acid for copolymerization with methacrylic esters, the incorporation of maleic acid is low, the cross-linking density is very high, the polymer coating is very thin, and the specific area is high. The final structure of the MIP network with a predominance of isolated functional units closely surrounded by cross-links yields a rigid material capable of preserving the memory of the model molecule of patulin in molecular imprints. Low reactivity of the functional monomer has beneficial effects regarding the binding selectivity for the target molecule compared to materials prepared from the more reactive methacrylic acid which lead to the formation of flexible polymer formed of short poly(methacrylic acid) sequences.

Similar content being viewed by others

References

Sellergren B (2001) Molecularly imprinted polymers. Man-made mimics of antibodies and their applications in analytical chemistry. Elsevier, Amsterdam

Haupt K, Mosbach K (1998) Plastic antibodies: developments and applications. Trends Biotechnol 16:468–475

Alvarez-Lorenzo C, Concheiro A (2013) Handbook of molecularly imprinted polymers. Smithers Rapra, Shawbury

Canfarotta F, Waters A, Sadler R, McGill P, Guerreiro A, Papkovsky D, Haupt K, Piletsky S (2016) Biocompatibility and internalization of molecularly imprinted nanoparticles. Nano Res 9:3463–3477

Ayadi C, Anene A, Kalfat R, Chevalier Y, Hbaieb S (2019) Molecularly imprinted polyaniline on silica support for the selective adsorption of benzophenone-4 from aqueous media. Colloids Surf A 567:32–42

Arfaoui F, Khlifi A, Bargaoui M, Khalfaoui M, Kalfat R (2018) Thin melamine imprinted sol gel coating on silica beads: experimental and statistical physics study. Chem Afr 1:175–185

Chianella I, Lotierzo M, Piletsky SA, Tothill IE, Chen B, Karim K, Turner APF (2002) Rational design of a polymer specific for microcystin-LR using a computational approach. Anal Chem 74:1288–1293

Karlsson BCG, O’Mahony J, Karlsson JG, Bengtsson H, Eriksson LA, Nicholls IA (2009) Structure and dynamics of monomer-template complexation: an explanation for molecularly imprinted polymer recognition site heterogeneity. J Am Chem Soc 131:13297–13304

Cowen T, Stefanucci E, Piletska E, Marrazza G, Canfarotta F, Piletsky SA (2020) Synthetic Mechanism of Molecular Imprinting at the Solid Phase. Macromolecules 53:1435–1442

Anene A, Kalfat R, Chevalier Y, Hbaieb S (2016) Molecularly imprinted polymer-based materials as thin films on silica supports for efficient adsorption of Patulin. Colloid Surf A 497:293–303

Anene A, Hosni K, Chevalier Y, Kalfat R, Hbaieb S (2016) Molecularly imprinted polymer for extraction of Patulin in apple juice samples. Food Control 70:90–95

Puel O, Galtier P, Oswald IP (2010) Biosynthesis and toxicological effects of patulin. Toxins 2:613–631

Wright SA (2015) Patulin in food. Curr Opin Food Sci 2:105–109

Tannous J, Atoui A, El Khoury A, Francis Z, Oswald IP, Puel O, Lteif R (2016) A study on the physicochemical parameters for Penicillium expansum growth and patulin production: effect of temperature, pH, and water activity. Food Sci Nutr 4:611–622

Anene A, Hosni K, Chevalier Y, Kalfat R, Hbaieb S (2017) Optimization of solid phase extraction based on molecularly imprinted polymer for patulin determination. J Tun Chem Soc 19:187–192

Thommes M, Kaneko K, Neimark AV, Olivier JP, Rodriguez-Reinoso F, Rouquerol J, Sing KSW (2015) Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl Chem 87:1051–1069

Ktari N, Fourati N, Zerrouki C, Ruan M, Seydou M, Barbaut F, Nal F, Yaakoubi N, Chehimi MM, Kalfat R (2015) Design of a polypyrrole MIP-SAW sensor for selective detection of flumequine in aqueous media. Correlation between experimental results and DFT calculations. RSC Adv 5:88666–88674

Cormack PAG, Zurutuza Elorza A (2004) Molecularly imprinted polymers: synthesis and characterisation. J Chromatogr B 804:173–182

Vasapollo G, Del Sole R, Mergola L, Lazzoi MR, Scardino A, Scorrano S, Mele G (2011) Molecularly imprinted polymers: present and future prospective. Int J Mol Sci 12:5908–5945

Fu X, Yang Q, Zhou Q, Lin Q, Wang C (2015) Template-monomer interaction in molecular imprinting: is the strongest the best? Open J Org Polym Mater 5:58–68

Zeynab T, Soleimani M, Mohammad M, Nikje A (2019) Characterization and performance evaluation of functional monomer effect on molecular imprinted polyurethane foam. J Chromatogr A 1602:30–40

Davies MP, De Biasi V, Perrett D (2004) Approaches to the rational design of molecularly imprinted polymers. Anal Chim Acta 504:7–14

Del Sole R, De Luca A, Catalano M, Mele G, Vasapollo G (2007) Noncovalent imprinted microspheres: preparation, evaluation and selectivity of DBU template. J Appl Polym Sci 105:2190–2197

Manning GS, Holtzer A (1973) Application of polyelectrolyte limiting laws to potentiometric titration. J Phys Chem 77:2206–2212

Dubin PL, Strauss UP (1970) Hydrophobic bonding in alternating copolymers of maleic acid. J Phys Chem 74:2842–2847

Dubin PL, Strauss UP (1967) Hydrophobic hypercoiling in copolymers of maleic acid and alkyl vinyl ethers. J Phys Chem 71:2757–2759

Sauvage E, Amos DA, Antalek B, Schroeder KM, Tan JS, Plucktaveesak N, Colby RH (2004) Amphiphilic maleic acid-containing alternating copolymers—1 Dissociation behavior and compositions. J Polym Sci Part B Polym Phys 42:3571–3583

Delben F, Paoletti S, Porasso RD, Benegas JC (2006) Potentiometric titrations of maleic acid copolymers in dilute aqueous solution: experimental results and theoretical interpretation. Macromol Chem Phys 207:2299–2310

Borukhov I, Andelman D, Borrega R, Cloitre M, Leibler L, Orland H (2000) Polyelectrolyte titration: theory and experiment. J Phys Chem B 104:11027–11034

Navarro-Villoslada F, San Vicente B, Moreno-Bondi MC (2004) Application of multivariate analysis to the screening of molecularly imprinted polymers for bisphenol A. Anal Chim Acta 504:149–162

Greenley RZ (1980) Recalculation of some reactivity ratios. J Macromol Sci Chem A 14:445–515

Świtała-Żeliazkow M (1999) Radical copolymerization of maleic acid with styrene. Eur Polym J 35:83–88

Greenley RZ (1999) Q and e values for free radical copolymerizations of vinyl monomers and telogens, Chap II. In: Brandrup J, Immergut EH, Grulke EA (eds) Polymer handbook, 4th edn. Wiley, New York, pp 309–320

Paxton TR (1963) Copolymerization reactivity ratios acrylic and methacrylic acids with butyl acrylate and butyl methacrylate. J Polym Sci B Polym Lett 1:73–76

Odian G (2004) Principles of polymerization, Chap 6. Hoboken, NJ, Wiley, New York, pp 464–484

Acknowledgements

This work was supported by funding from the “Partenariat Hubert Curien Utique” for French−Tunisian cooperation, Grant no. 19G1204.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Anene, A., Kalfat, R., Chevalier, Y. et al. Design of Molecularly Imprinted Polymeric Materials: The Crucial Choice of Functional Monomers. Chemistry Africa 3, 769–781 (2020). https://doi.org/10.1007/s42250-020-00180-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42250-020-00180-1