Abstract

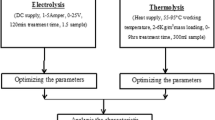

Sugarcane industries have a major contribution to the rural development of country, including pollution level to the environment. Associate with all the waste from the sugarcane industry, wastewater is a key issue to manage. Throughout the sugarcane processing season, large quantities of water consumed and discharge a large amount of wastewater. The investigation has been done to bring wastewater up to recycling limit made by pollution board. The objective of this research work is to reduced the pollutants from sugar industry effluent with thermal oxidation, electrooxidation, and combined with both treatment process. The result shows 68.5% COD and 71.2% color with thermal, 82.5% COD, and 86.5% color with electrocoagulation and 98% COD and 99.2% color reduction with a combined treatment of most appropriate conditions. In settling and filtration study 80% of efficiency was attained with the combined study. The sludge containing a lesser amount of inorganic and treated can be reutilized.

Similar content being viewed by others

References

Frenkel Y (2019) The Mamluk sultanate and its neighbours: economic, social and cultural entanglements. Mamluk Studies, 39–40

de Miranda EE, Fonseca MF (2020) Sugarcane: food production, energy, and environment. Sugarcane Biorefinery, Technology and Perspectives. Academic Press, Cambridge, pp 67–88

Asaithambi P, Matheswaran M (2016) Electrochemical treatment of simulated sugar industrial effluent: optimization and modeling using a response surface methodology. Arab J Chem 9:S981–S987

Bhatnagar A, Kesari KK, Shurpali N (2016) Multidisciplinary approaches to handling wastes in sugar industries. Water Air Soil Pollut 227(1):11

Sharma C, Kumar V (2015) Analysis of the volume of the main water and wastewater in a sugar manufacturing process followed by the suggestion regarding the reutilization of the waste water. In J Curr Eng Tech 5(3):1757–1761

Freyria FS, Armandi M, Compagnoni M, Ramis G, Rossetti I, Bonelli B (2017) Catalytic and photocatalytic processes for the abatement of n-containing pollutants from wastewater. Part 2: organic pollutants. J Nanosci Nanotechnol 17(6):3654–3672

Hameed YT, Idris A, Hussain SA, Abdullah N (2016) A tannin-based agent for coagulation and flocculation of municipal wastewater: chemical composition, performance assessment compared to Polyaluminum chloride, and application in a pilot plant. J Environ Manage 184:494–503

Garg A, Mishra IM, Chand S (2005) Thermochemical precipitation as a pretreatment step for the chemical oxygen demand and colour removal from pulp and paper mill effluent. Ind Engg Chem Res 44:2016–2026

Chaudhari PK, Mishra IM, Chand S (2008) Effluent treatment for alcohol distillery: catalytic thermal pretreatment (Catalytic thermolysis) with energy recovery. Chem Eng Journal 136:14–24

Verma S, Prasad B, Mishra IM (2011) Thermochemical treatment (Thermolysis) of petrochemical wastewater: COD removal mechanism and Floc formation. Ind Eng Chem Res 50(9):5352–5359

Sahu OP, Chaudhari PK (2015) Removal of color and chemical oxygen demand from sugar industry wastewater using thermolysis processes. Desalin Water Treat 56(7):1758–1767

Devi P, Das U, Dalai AK (2016) In-situ chemical oxidation: principle and applications of peroxide and persulfate treatments in wastewater systems. Sci Total Environ 571:643–657

Sahu O (2017) Catalytic thermal pre-treatments of sugar industry wastewater with metal oxides: thermal treatment. Exp Thermal Fluid Sci 85:379–387

Mook WT, Aroua MK, Szlachta M, Lee CS (2017) Optimisation of Reactive Black 5 dye removal by electrocoagulation process using response surface methodology. Water Sci Technol 75(4):952–962

Lindholm-Lehto PC, Knuutinen JS, Ahkola HS, Herve SH (2015) Refractory organic pollutants and toxicity in pulp and paper mill wastewaters. Environ Sci Pollut Res 22(9):6473–6499

Sahu O, Mazumdar B, Chaudhari PK (2014) Treatment of wastewater by electrocoagulation: a review. Environ Sci Pollut Res 21(4):2397–2413

Deokate A (2015) Development of textile waste water treatment reactor to obtain drinking water by solar powered electro-coagulation technique. J Res En Sci Tech 5(1):29–34

Ulucan K, Kabuk AK, Ilhan F, Kurt U (2014) Electrocoagulation process application in bilge water treatment using response surface methodology. In J Electrochem Sci 9:2316–2326

Kim DG, Kim WY, Yun CY, Son D, Chang D, Bae HS, Lee YH, Sunwoo Y, Hong KH (2013) Agro-industrial wastewater treatment by electrolysis technology. J Electrochem Sci 8:9835–9850

Lee KM, Lai CW, Ngai KS, Juan JC (2016) Recent developments of zinc oxide based photocatalyst in water treatment technology: a review. Water Res 88:428–448

Valipour M (2015) Land use policy and agricultural water management of the previous half of century in Africa. Appl Water Sci 5(4):367–395

Zazou H, Afanga H, Akhouairi S, Ouchtak H, Addi AA, Akbour RA, Assabbane A, Douch J, Elmchaouri A, Duplay J, Jada A (2019) Treatment of textile industry wastewater by electrocoagulation coupled with electrochemical advanced oxidation process. J Water Process Eng 28:214–221

Sahu OP, Chaudhari PK (2015) Electrochemical treatment of sugar industry wastewater: COD and color removal. J Electroanal Chem 739:122–129

APHA (1989) Standard Methods for Examination of Water and Wastewater. In: 20th ed. Washington, DC: American Public Health Association

Chaudhari PK, Mishra IM, Chand S (2007) Decolourization and removal of chemical oxygen demand (COD) with energy recovery: Treatment of biodigester effluent of a molasses-based alcohol distillery using inorganic coagulants. Colloids Surf A Physicochem Engg Asp 296:238–247

Kumar P, Prasad B, Mishra IM, Chand S (2008) Decolorization and COD reduction of dyeing wastewater from a cotton textile mill using thermolysis and coagulation. J Hazard Mat 153:635–645

Shi J, Zhang B, Liang S, Li J, Wang Z (2018) Simultaneous decolorization and desalination of dye wastewater through electrochemical process. Environ Sci Pollut Res 25(9):8455–8464

Naje AS, Chelliapan S, Zakaria Z, Abbas SA (2015) Enhancement of an electrocoagulation process for the treatment of textile wastewater under combined electrical connections using titanium plates. In J Electrochem Sci 10:4495–4512

Anawar HM, Ahmed G (2019) Combined electrochemical-advanced oxidation and enzymatic process for treatment of wastewater containing emerging organic contaminants. Emerging and nanomaterial contaminants in wastewater. Elsevier, Amsterdam, pp 277–307

Tiwari A, Sahu O (2017) Treatment of food-agro (sugar) industry wastewater with copper metal and salt: chemical oxidation and electro-oxidation combined study in batch mode. Water Resour Ind 17:19–25

Vahidifar S, Saffarian MR, Hajidavalloo E (2019) Numerical simulation of particle-laden flow in an industrial wastewater sedimentation tank. Meccanica 54(15):2367–2383

Sahu O, Rao DG, Gopal R, Tiwari A, Pal D (2017) Treatment of wastewater from sugarcane process industry by electrochemical and chemical process: aluminum (metal and salt). J Water Process Eng 17:50–62

MaCabe WL, Smith JC, Harriot P (2001) Unit operations of chemical engineering, 6th edn. McGraw-Hill, New York

Ahmad R, Aslam M, Park E, Chang S, Kwon D, Kim J (2018) Submerged low-cost pyrophyllite ceramic membrane filtration combined with GAC as fluidized particles for industrial wastewater treatment. Chemosphere 206:784–792

Chao Z, Lin Y, Junqiang S, Bengao L, Tao L (2018) Evaluation of powdered activated carbon treatment process in petrochemical wastewater purification. China Pet Process Petrochem Technol 20(4):67–74

Prakash N, Soundarrajan M, Vendan SA, Sudha PN, Renganathan NG (2017) Contemplating the feasibility of vermiculate blended chitosan for heavy metal removal from simulated industrial wastewater. Appl Water Sci 7(8):4207–4218

Ismail HM, Elmalky MG, Hashem AI, Hafez AI (2019) Preparation and characterization of modified corncobs to be used as coagulant material in industrial waste water treatment. J Environ Sci 45(3):21–47

Sahu O, Mazumdar B, Chaudhari PK (2019) Electrochemical treatment of sugar industry wastewater: process optimization by response surface methodology. Int J Environ Sci Technol 16(3):1527–1540

Acknowledgements

Author acknowledge to Department of Chemical and Petroleum Engineering, UIE, Chandigarh University Mohali (Punjab) for providing lab facilities

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares no conflicts of interest.

Rights and permissions

About this article

Cite this article

Sahu, O. Deduction of Organic and Inorganic Pollutant from Sugarcane Processing Plant Effluent by Thermal-oxidation and Electro-oxidation Processes in Batch Experiment. Chemistry Africa 3, 965–978 (2020). https://doi.org/10.1007/s42250-020-00167-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42250-020-00167-y