Abstract

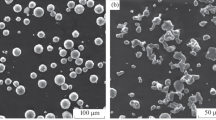

Si3N4–TiN–SiC composites were prepared by partial substitution of the Ti–Si–Fe alloy extracted from high-titanium blast furnace slag for Si under nitrogen atmosphere. The nitridation, microstructure and mechanical properties of the composites were investigated in detail. The results show that Ti–Si–Fe alloy facilitated the nitridation of Si and full nitridation of Si was achieved in the compacts with 3.6–5.4 wt.% Ti–Si–Fe alloy additive, and thus, densification and mechanical performances of the composites were improved obviously. Propagating of microcracks induced by the volume expansions accompanying with the conversion of Ti5Si3 and TiSi2 to nitrides at 950–1050 °C built new N2(g) transport channels in the compacts. In the following up nitridation process, adequate N2(g) was transported through these channels into the compacts to fundamentally enhance contact of N2 with Si, facilitate and ensure the complete nitridation of internal Si. Moreover, the Ti–Si–Fe–Mn–N eutectic liquid played an important role in the formation of both α- and β-Si3N4, and the Fe in the Ti–Si–Fe alloy was of great importance for the formation of fibrous Si3N4 by the reaction between SiO(g) and N2(g).

Similar content being viewed by others

References

F. Liang, W. Zhao, L. Lu, H. Zhang, Y. Bi, J. Zhang, J. Liu, S. Zhang, Metall. Mater. Trans. A 50 (2019) 348–356.

Z. Wang, E. Skybakmoen, T. Grande, J. Am. Ceram. Soc. 92 (2009) 1296–1302.

H. Chen, J. Liu, W. Huang, Mater. Sci. Eng. A 415 (2006) 291–296.

M. Long, Y. Li, H. Qin, W. Xue, P. Jiang, J. Sun, R.V. Kumar, Ceram. Int. 43 (2017) 10720–10725.

H. Klemm, J. Am. Ceram. Soc. 93 (2010) 1501–1522.

W. Wu, J. Gui, S. Wei, W. Xue, Z. Xie, J. Eur. Ceram. Soc. 36 (2016) 2667–2672.

P. Tatarko, M. Kašiarová, J. Dusza, P. Šajgalík, J. Eur. Ceram. Soc. 33 (2013) 2259–2268.

J. Chen, N. Li, Y. Wei, B. Han, W. Yan, J. Eur. Ceram. Soc. 37 (2017) 1821–1829.

M. Rosa, F. Casaril, M. Valle, S. Poli, Ceram. Eng. Sci. Proceed. 35 (2015) 245–257.

X. Zhu, Y. Zhou, K. Hirao, J. Mater. Sci. 39 (2004) 5785–5797.

M. Long, Y. Li, X. Jin, G. Yao, J. Sun, R.V. Kumar, J. Am. Ceram. Soc. 101 (2018) 4350–4356.

C. Ma, Y. Li, P. Jiang, X. Yue, J. Alloy. Compd. 938 (2023) 168723.

C. Chen, X. Liang, M. Luo, S. Zhou, J. Ji, Z. Huang, M. Xu, Ceram. Int. 45 (2019) 5922–5926.

H.L. Hu, Y.P. Zeng, K.H. Zuo, Y.F. Xia, D.X. Yao, J. Günster, J.G. Heinrich, S. Li, J. Eur. Ceram. Soc. 35 (2015) 3781–3787.

J. Huang, Z. Huang, S. Yi, Y.G. Liu, M. Fang, S. Zhang, Sci. Rep. 3 (2013) 3504.

J. Huang, Y.G. Liu, Z. Huang, M. Fang, S. Zhang, W. Xie, J. Yang, S. Huang, Y. Xu, Cryst. Growth Des. 13 (2013) 10–14.

J. Huang, S. Zhang, Z. Huang, Y. Wen, M. Fang, Y. Liu, CrystEngComm 14 (2012) 7301.

L. Zivkovic, Z. Nikolic, S. Boskovic, M. Miljkovic, J. Alloy. Compd. 373 (2004) 231–236.

H. Borodianska, L. Krushinskaya, G. Makarenko, Y. Sakka, I. Uvarova, O. Vasylkiv, J. Nanosci. Nanotech. 9 (2009) 6381–6389.

L. Maillé, Y. Le Petitcorps, J. Roger, J. Eur. Ceram. Soc. 37 (2017) 3885–3889.

H. Alhussain, T. Mise, K. Kobayashi, H. Kiyono, J. Ceram. Soc. Japan 128 (2020) 677–684.

H. Ding, X. Zhang, Q. Liu, W. Miao, J. Zhou, J. Wang, J. Mater. Res. Technol. 14 (2021) 1709–1723.

L. Han, L. Dong, F. Li, H. Duan, H. Zhang, G. Li, Q. Jia, S. Zhang, J. Eur. Ceram. Soc. 42 (2022) 2699–2706.

J.C. Han, G.Q. Chen, S.Y. Du, J.V. Wood, J. Eur. Ceram. Soc. 20 (2000) 927–932.

X.J. Zhang, Y.T. Zheng, J.C. Han, X.H. Yang, Mater. Sci. Forum 546-549 (2007) 1615–1618.

X. Zhang, Y. Zheng, J. Han, L. Zhou, Journal of the Chinese Ceramic Society 34 (2006) 708–712.

J.H. Zhang, S. Xiong, C.M. Ke, H.D. Wu, X.R. Lei, Key Eng. Mater. 768 (2018) 159–166.

L. Yao, C. Ke, J. Zhang, Y. Li, B. Han, J. Wang, Ceram. Int. 48 (2022) 31203–31210.

Z. Chen, W. Yan, Y. Dai, S. Schafföner, B. Han, N. Li, Ceram. Int. 45 (2019) 8533–8538.

L. Maillé, M.A. Dourges, S. Le Ber, P. Weisbecker, F. Teyssandier, Y. Le Petitcorps, R. Pailler, Appl. Surf. Sci. 260 (2012) 29–31.

M. Long, Y. Li, H. Qin, W. Xue, J. Chen, J. Sun, R. Vasant Kumar, Ceram. Int. 42 (2016) 16448–16452.

S.M. Boyer, A.J. Moulson, J. Mater. Sci. 13 (1978) 1637–1646.

X. Qin, J. Zhang, C. Ke, H. Chen, L. Zhao, Inorg. Chem. Commun. 148 (2023) 110278.

Y. Ge, S. Sun, Q. Wang, W. Cui, Y. Zou, Z. Xie, K. Chen, J. Am. Ceram. Soc. 99 (2016) 1464–1471.

B. Ma, Y. Tang, C. Deng, Int. J. Appl. Ceram. Technol. 19 (2022) 2523–2532.

L. Sun, Y. Tang, Y. Cui, T. Du, C. Zhou, B. Ma, J. Wang, Int. J. Appl. Ceram. Technol. 20 (2023) 1269–1277.

L. Han, J. Wang, F. Li, H. Wang, X. Deng, H. Zhang, S. Zhang, J. Eur. Ceram. Soc. 38 (2018) 1210–1218.

Y. Bi, H. Wang, L. Huang, J. Wang, H. Zhang, S. Zhang, Ceram. Int. 43 (2017) 15755–15761.

X. Guo, J. Gu, X. Hu, S. Zhang, Z. Chen, S. Huang, Catal. Today 350 (2020) 91–99.

L. Gao, F. Wang, M.A. Yu, F. Wei, J. Qi, S. Lin, D. Xie, J. Mater. Chem. A 7 (2019) 19838–19845.

Acknowledgements

This work was supported by the Open Foundation of the State Key Laboratory of Refractories and Metallurgy (Grant No. 2018QN11) and National Science and Technology Pillar Program during the Twelfth Five-Year Plan (Grant No. 2011BAB05B05).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yao, Ly., Zhang, Jh., Han, Bq. et al. Preparation of Si3N4–TiN–SiC composite by partial substitution of Ti–Si–Fe alloy for Si under N2 atmosphere. J. Iron Steel Res. Int. (2024). https://doi.org/10.1007/s42243-024-01196-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42243-024-01196-4