Abstract

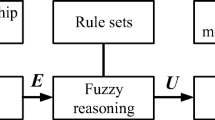

The hot rolling and cold rolling control models of silicon steel strip were examined. Shape control of silicon steel strip of hot rolling was a theoretical analysis model, and the shape control of cold rolling was a data-based prediction model. The mathematical model of the hot-rolled silicon steel section, including the crown genetic model, inter-stand crown recovery model, and hot-rolled strip section prediction model, is used to control the shape of hot-rolled strip. The cold rolling shape control is mainly based on Takagi-Sugeno fuzzy network, which is used to simulate and predict the transverse thickness difference of cold-rolled silicon steel strip. Finally, a predictive model for the transverse thickness difference of silicon steel strips is developed to provide a new quality control method of transverse thickness of combined hot and cold rolling to improve the strip profile quality and increase economic efficiency. The qualified rate of the non-oriented silicon steel strip is finally obtained by applying this model, and it has been steadily upgraded to meet the needs of product quality and flexible production.

Similar content being viewed by others

References

Z. Xia, Y. Kang, Q. Wang, J. Magn. Magn. Mater. 320 (2008) 3229–3233.

G.T. Liu, Z.Q. Liu, P. Yang, W.M. Mao, J Iron Steel Res. Int. 23 (2016) 1234–1242.

K. Yasuda, K. Narita, K. Kobayashi, I. Maeno, ISIJ Int. 31 (2007) 594–598.

S. Omori, T. Kajiwara, H. Hino, H. Goto, Ironmak. Steelmak. 31 (2004) 71–80.

J.S. Son, D.M. Lee, I.S. Kim, S.G. Choi, J. Mater. Process. Technol. 164–165 (2005) 1612–1617.

Y. Hu, D.Y. Gong, Z.Y. Jiang, J.Z. Xu, D.H. Zhang, X.H. Liu, J. Iron Steel Res. Int. 16 (2009) No. 5, 32–34.

M. Bagheripoor, H. Bisadi, Appl. Math. Model. 37 (2013) 4593–4607.

X.C. Wang, Q. Yang, Y.Z. Sun, J. Iron Steel Res. Int. 22 (2015) 185–191.

E.A. Maklakova, A.S. Maklakov, V.R. Gasiyarov, S.S. Voronin, Procedia Eng. 129 (2015) 37–41.

G. Song, X. Wang, Q. Yang, Int. J. Adv. Manuf. Technol. 97 (2018) 2675–2686.

M. Rout, S.K. Pal, S. Singh, J. Manuf. Process. 31 (2018) 301–309.

H.N. He, J. Shao, X. Wang, Q. Yang, Y. Liu, D. Xu, Y. Sun, J. Iron Steel Res. Int. 28 (2021) 279–290.

H.N. He, J. Shao, X. Wang, Q. Yang, X. Feng, Metals 10 (2020)401.

S.M. Awatade, R. Suhane, Materials Today 58 (2022) 744–748.

L. Li, H. Xie, T. Liu, M. Huo, X. Liu, X. Li, K. Shi, J. Li, H. Liu, L. Sun, Z. Jiang, J. Manuf. Process. 81 (2022) 505–521.

S. Shen, D. Guye, X. Ma, S. Yue, N. Armanfard, Mach. Learn. Appl. 7 (2022) 100245.

J. Zhao, X. Wang, Q. Yang, Q. Wang, C. Liu, G. Song, J. Mater. Process. Technol. 265 (2019) 99–111.

J. Li, X. Wang, Q. Yang, Z. Guo, L. Song, X. Mao, Int. J. Adv. Manuf. Technol. 121 (2022) 4087–4098.

M. Han, Y.N. Sun, Y.N. Fan, Expert Syst. Appl. 34 (2008) 2905–2920.

Z.H. Wang, D.Y. Gong, X. Li, G.T. Li, D.H. Zhang, Int. J. Adv. Manuf. Technol. 93 (2017) 3325–3338.

Acknowledgements

This work was financially supported by the National Key Research and Development Plan of China (No. 2020YFB1713600), the National Natural Science Foundation of China (No. 51975043), the Fundamental Research Funds for the Central Universities (Nos. FRF-TP-19-002A3 and FRF-TP-20-105A1), and the China Postdoctoral Science Foundation (No. 2021M690352).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Xiao-chen Wang and Jian Shao are youth editorial board members for Journal of Iron and Steel Research International and were not involved in the editorial review or the decision to publish this article. The authors declare that there is no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

He, Hn., Dai, Zh., Wang, Xc. et al. Whole process prediction model of silicon steel strip on transverse thickness difference based on Takagi-Sugeno fuzzy network. J. Iron Steel Res. Int. 30, 2448–2458 (2023). https://doi.org/10.1007/s42243-023-01094-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-023-01094-1