Abstract

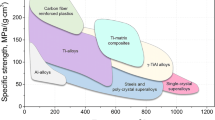

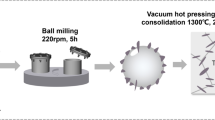

A porous yttrium oxide crucible with both thermal shock resistance and erosion resistance was developed by structural optimization. The structure-optimized yttrium oxide crucible was proved to be suitable for melting highly reactive titanium alloys. Low-cost (TiB + Y2O3)-reinforced titanium matrix composites were prepared by vacuum induction melting using the prepared crucible. The thermal deformation behavior and microstructure evolution of (TiB + Y2O3)-reinforced titanium matrix composites were investigated at deformation temperatures of 900–1100 °C with strain rates of 0.001–1 s−1. The results showed that the prepared yttrium oxide crucible had both thermal shock and erosion resistance, the low-cost titanium matrix composites could be prepared by the developed yttrium oxide crucibles which were homogeneous in composition and highly sensitive to strain rate and deformation temperature, and the peak and rheological stresses decreased with increasing deformation temperature or decreasing strain rate. In addition, the average thermal deformation activation energy of the composites was calculated to be 574.6 kJ/mol by establishing the Arrhenius constitutive equation in consideration of the strain variables, and the fitting goodness between the predicted stress value and the measured value was 97.624%. The calculated analysis of the hot processing map showed that the best stable thermal deformation zone was located in the deformation temperature range of 1000–1100 °C and strain rate range of 0.001–0.01 s−1, where the peak dissipation coefficient was η = 71%. In this zone, the deformation of the reinforcement and matrix was harmonious, the reinforcement was less likely to fracture, dynamic recrystallization occurred more fully and the alloy exhibited near steady rheological characteristics.

Similar content being viewed by others

References

P. Qiu, J. Le, Y. Han, Y. Chen, G. Huang, J. Mao, L. Lei, W. Lu, Compos. B 238 (2022) 109940.

V.A. Popov, E.V. Shelekhov, A.S. Prosviryakov, M.Y. Presniakov, B.R. Senatulin, A.D. Kotov, M.G. Khomutov, J. Alloy. Compd. 707 (2017) 365–370.

W.D. Song, Y.M. Yang, J.G. Ning, J. Nano Res. 23 (2013) 104–107.

B.J. Choi, I.Y. Kim, Y.Z. Lee, Y.J. Kim, Wear 318 (2014) 68–77.

Q. Lu, Y. Lv, C. Zhang, S. Jiang, J.L. Fan, J. Alloy. Compd. 901 (2022) 163521.

X. Lin, H. Huang, F. Dong, Y. Zhang, X. Yuan, B. Zheng, X. Zuo, Acta Metall. Sin. (Engl. Lett.) 34 (2021) 1747–1757.

C.J. Zhang, J.P. Qu, J. Wu, S.Z. Zhang, J.C. Han, M.D. Hayat, P. Cao, Mater. Lett. 233 (2018) 242–245.

J. Li, L. Wang, J. Qin, Y. Chen, W. Lu, D. Zhang, Mater. Charact. 66 (2012) 93–98.

J.Q. Qi, H.W. Wang, C.M. Zou, Z.J. Wei, Mater. Sci. Eng. A 553 (2012) 59–66.

O.O. Ayodele, P.A. Olubambi, Int. J. Eng. Res. Africa 62 (2022) 19–30.

S.C. Sun, E.T. Zhao, C. Hu, Y.J. Tian, W.Z. Chen, H.Z. Cui, R.R. Chen, J. Mater. Res. Technol. 9 (2020) 13250–13263.

C. Zhang, S. Zhang, P. Lin, Z. Hou, F. Kong, Y. Chen, J. Mater. Res. 31 (2016) 1244–1253.

H.B. Wang, S.S. Wang, P.Y. Gao, T. Jiang, X.G. Lu, C.H. Li, Mater. Sci. Eng. A 672 (2016) 170–174.

C. Tan, Z.Y. Chen, Z.L. Xiang, X.Z. Ma, Z.A. Yang, Mater. Sci. Forum 1035 (2021) 89–95.

C. Zhao, R.Y. Wang, K.J. Pan, M.H. Sun, N. Li, Chin. Sci. Bull. 67 (2022) 1155–1166.

T. Tetsui, T. Kobayashi, H. Harada, Mater. Sci. Eng. A 552 (2012) 345–352.

F. Simbarashe, L. Mykhaylo, D.W. Moegamat, P. Lydia, L. Vladimir, T. Sun, R.H. Tang, F.M. Xiao, F.V. Pavel, T.P. Boris, Mater. Des. 186 (2020) 108295.

W. Szkliniarz, A. Szkliniarz, Metals 11 (2021) 669.

A. Kostov, B. Friedrich, D. Zivkovic, Comput. Mater. Sci. 37 (2006) 355–360.

Q.L. Li, H.R. Zhang, M. Gao, J.P. Li, H. Zhang, J. Mater. Process. Technol. 294 (2021) 117094.

T. Tetsui, T. Kobayashi, A. Kishimoto, H. Harada, Intermetallics 20 (2012) 16–23.

T. Tetsui, T. Kobayashi, T. Ueno, H. Harada, Intermetallics 31 (2012) 274–281.

C.J. Zhang, F.T. Kong, S.L. Xiao, E.T. Zhao, L.J. Xu, Y.Y. Chen, Mater. Sci. Eng. A 548 (2012) 152–160.

M. Yi, X. Zhang, G. Liu, B. Wang, H. Shao, G. Qiao, Mater. Charact. 140 (2018) 281–289.

Y. Yang, A.J. Huang, F. Xu, G.P. Li, Chin. J. Nonferrous Met. 15 (2005) 768–774.

N. Tahreen, D.F. Zhang, F.S. Pan, X.Q. Jiang, C. Li, D.Y. Li, D.L. Chen, J. Alloy. Compd. 644 (2015) 814–823.

B. Wang, L.J. Huang, L. Geng, X.D. Rong, Mater. Sci. Eng. A 648 (2015) 443–451.

R. Bobbili, V. Madhu, J. Alloy. Compd. 762 (2018) 842–848.

Y.V.R.K. Prasad, H.L. Gegel, S.M. Doraivelu, J.C. Malas, J.T. Morgan, K.A. Lark, D.R. Barker, Metall. Trans. A 15 (1984) 1883–1892.

Y. Bao, D.Y. Yang, N. Liu, G.Q. Zhang, Z. Li, F.Y. Cao, J.F. Sun, J. Iron Steel Res. Int. 24 (2017) 435–441.

R. Mahdavi, E. Emadoddin, S.M. Abbasi, Trans. Indian Inst. Met. 75 (2022) 2639–2650.

X. Lin, H. Huang, X. Yuan, Y. Wang, B. Zheng, X. Zuo, G. Zhou, J. Alloy. Compd. 901 (2022) 163648.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (52071065), the Fundamental Research Funds for the Central Universities (N2007007), the National Key R&D Program of China (2016YFB-0301201), and the Ten Technology Research Projects of Hunan Province (No. 2022GK1050).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dang, Q., Huang, G., Wang, Y. et al. Mechanical properties and thermal deformation behavior of low-cost titanium matrix composites prepared by a structure-optimized Y2O3 crucible. J. Iron Steel Res. Int. 31, 738–751 (2024). https://doi.org/10.1007/s42243-023-01093-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-023-01093-2