Abstract

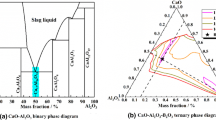

To provide theoretical guidance for performance stability control of low-reactive mold fluxes, the effects of BaO and MgO on the structure and properties of aluminate slag with various CaO/Al2O3 (C/A) ratios were investigated using the Fourier transform infrared spectrometer, Raman spectroscope, hemispherical melting point instrument, rotational viscometer and X-ray diffractometer. The results indicated that with BaO and MgO addition, the structure polymerization was first weakened and then enhanced at C/A of 1.1, and the transition contents corresponded to 8 wt.% BaO and 2 wt.% MgO, respectively, while the structure polymerization decreased continuously at C/A of 1.3. Since the viscosity change was well consistent with the structure evolution, the polymerization degree played a more prominent role in the slag viscosity than superheat degree when the melting temperature difference was within 40 °C. The break temperature decreased initially and then increased with augment of BaO and MgO at C/A of 1.1, while it manifested a decrease trend with BaO addition, and it decreased obviously but then turned to increase with MgO increment at C/A of 1.3. The crystallization phase and crystallization ratio kept stable with BaO increment, while the crystallization ratio rose greatly with MgO promoting LiAlO2 precipitation at C/A of 1.1. The crystal types of all experimental slags were mainly Ca12Al14O33 and CaF2 at C/A of 1.3, and the precipitation of crystalline phase BaAl2O4 demonstrated a rising trend, while that of Ca12Al14O33 gradually declined with BaO augment.

Similar content being viewed by others

References

Z.H. Jiang, Y.W. Dong, H.B. Li, X.M. Zang, Chinese Metallurgy 21 (2011) No. 12, 1–10.

Q. Sun, Times Agricultural Machinery 45 (2018) No. 6, 183.

Y.Q. Li, Y.L. Yu, L.F. Zhang, Z.T. Li, Metall. Res. Technol. 119 (2022) 101.

B. Xie, Research on basic theory of mold flux and its application practice, Chongqing University, Chongqing, China, 2004.

Z.M. Zhu, C. Zhang, D.X. Cai, T. Zhuang, Mold fluxes for high aluminum steel and its manufacturing method, China, CN101332497, 2008.

K. Blazek, H. Yin, G. Skoczylas, M. McClymonds, M. Frazee, T.C. Mao, J.X. Liu, World Iron & Steel 13 (2013) No. 3, 8–17.

J.W. Cho, K. Blazek, M. Frazee, H. Yin, J.H. Park, S.W. Moon, ISIJ Int. 53 (2013) 62–70.

Q. Liu, G. Wen, J. Li, X. Fu, P. Tang, W. Li, Ironmak. Steelmak. 41 (2014) 292–297.

J.L. Liao, Y.Y. Zhang, S. Sridhar, X.D. Wang, Z.T. Zhang, ISIJ Int. 52 (2012) 753–758.

W. Yan, W. Chen, Y. Yang, C. Lippold, A. McLean, Ironmak. Steelmak. 42 (2015) 698–704.

C.B. Shi, M.D. Seo, J.W. Cho, S.H. Kim, Metall. Mater. Trans. B 45 (2014) 1081–1097.

C. Xiao, Molecular dynamics simulation of microstructure and properties of CaO–SiO2–Al2O3–Na2O system melts, Jiangxi University of Science and Technology, Ganzhou, China, 2017.

T. Wu, Q. Wang, T.H. Yao, S.P. He, J. Non-Cryst. Solids 435 (2016) 17–26.

K. Yang, Y.S. Hu, Z. Li, N.M. Anoop Krishnan, M.M. Smedskjaer, C.G. Hoover, J.C. Mauro, G. Sant, M. Bauchy, J. Am. Ceram. Soc. 104 (2021) 3947–3962.

W.G. Kong, J.H. Liu, Y.W. Yu, X.M. Hou, Z.J. He. J. Iron Steel Res. Int. 28 (2021) 1223–1232.

J.C. Du, L.R. Corrales, J. Non-Cryst. Solids 353 (2007) 210–214.

S.P. He, Y. Chen, W.J. Pan, Q.Q. Wang, X.B. Zhang, Q. Wang, J. Iron Steel Res. 32 (2020) 771–779.

J.R. Allwardt, B.T. Poe, J.F. Stebbins, Am. Mineral. 90 (2005) 1453–1457.

Z.J. Wang, I. Sohn, J. Am. Ceram. Soc. 101 (2018) 4285–4295.

B. Lu, W.L. Wang, Metall. Mater. Trans. B 46 (2015) 852–862.

S. Sadaf, J. Lei, H.X. Zhuang, T. Wu, H.C. Wang. Metall. Res. Technol. 119 (2022) 208.

Z.L. Piao, L.G. Zhu, X.J. Wang, P.C. Xiao, J.Y. Zhou. B. Wang, S. Qu, K. Liu, J. Non-Cryst. Solids 542 (2020) 120111.

J. Lei, W. Yang, G.Y. Sheng, C. Zhang, T. Wu. H.C. Wang, Metall. Mater. Trans. B 53 (2022) 2239–2247.

S. Sukenaga, N. Saito, K. Kawakami, K. Nakashima, ISIJ Int. 46 (2006) 352–358.

C.H. Jiang, K.J. Li, J.L. Zhang, Q.H. Qin, Z.J. Liu, W. Liang, M.M. Sun, Z.M. Wang, Metall. Mater. Trans. B 50 (2019) 367–375.

E.Z. Gao, W.L. Wang, L. Zhang, J. Non-Cryst. Solids 473 (2017) 79–86.

P.C. Li, X.J. Ning, Metall. Mater. Trans. B 47 (2016) 446–457.

Y.M. Gao, S.B. Wang, C. Hong, J.X. Ma, F. Yang, Int. J. Miner. Metall. Mater. 21 (2014) 353–362.

J.F. Xu, J.Y. Zhang, C. Jie, F. Ruan, K.C. Chou, Ironmak. Steelmak. 38 (2011) 329–337.

X. Yu, G.H. Wen, P. Tang, F.J. Ma, H. Wang, J. Iron Steel Res. Int. 18 (2011) No. 1, 20–25.

K.H. Moon, M.S. Park, S. Yoo, J.K. Park, J.W. Cho, G. Shin, in: F. Marquis (Eds.), Proceedings of the 8th Pacific Rim International Congress on Advanced Materials and Processing, The Minerals, Metals & Materials Series. Springer, Cham, 2016. pp. 735–745.

S.P. He, Q. Wang, J.H. Zeng, M. Zhang, B. Xie, J. Iron Steel Res. 21 (2009) No. 12, 59–62.

W.P. Tong, Z. Han, L.M. Wang, J. Lu, K. Lu, Surf. Coat. Technol. 202 (2008) 4957–4963.

Z.Y. Chen, Z.G. Lin, J.J. Qi, Y. Feng, L.Q. Chen, G.D. Wang, Acta Metall. Sin. (Engl. Lett.) 35 (2022) 1131–1142.

C.Q. Hu, X.L. Wang, X.F. Shi, Z.X. Wang, W.G. Han, J. Iron Steel Res. Int. 32 (2020) 103–110.

X. Feng, W. Yao, J.L. Li, Continuous Casting (2021) No. 2, 38–42.

G.Y. Sheng, W. Yang, L. Zhao, Z.Y. Liao, T. Wu, Continuous Casting (2021) No. 2, 14–18.

Acknowledgements

The authors would like to deeply appreciate the fund support from the Natural Science Foundation of Anhui Provincial Education Department (KJ2021A0358) and the National Natural Science Foundation of China (51804004).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare that there are no known conflicts of interest associated with this publication and there has been no significant financial support for this work that could have influenced its outcome.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kong, Yq., Wu, T., Xia, Wz. et al. Effect of BaO and MgO on structure and properties of aluminate slag with various CaO/Al2O3 ratios. J. Iron Steel Res. Int. 31, 204–214 (2024). https://doi.org/10.1007/s42243-023-01051-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-023-01051-y