Abstract

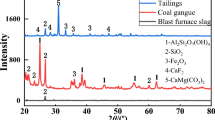

Preparation of ceramsite from solid waste based on the sintering process is a new technology and had a high efficiency in improving producing capability, decreasing consumption of liquefied petroleum gas (LPG), and recovering waste heat of flue gas. An experiment sintering gangue ceramsite was conducted in a 25 kg scale sintering pot with a 100 cm height. The combustion characteristics, phase transformation, and the release profile of SO2* (SO and/or SO2) and NOx* (N2O, NO, and/or NO2) of gangue ceramsite during the sintering process were studied by X-ray diffraction analysis, X-ray fluorescence spectrometry, thermogravimetry–differential thermogravimetry–differential scanning calorimetry, and measurement of physical properties of ceramsite and gas components of flue gas. The results showed that the gangue ceramsite had excellent properties, and its compressive strength and water absorption were 8.2–9.6 MPa and 8.9%–9.8%, respectively, far exceeding the requirement of standard (GB/T 17431.1–2010). The ignition temperature of gangue ceramsite was 443 °C, and the ignition loss was 14.60 mass% at 1000 °C. Kaolinite and calcite disappeared at 600 and 800 °C, respectively. Albite disappeared and mullite formed at 1000 °C. Two peaks of SO2* emissions emerged in the range of 311–346 mg m−3 near 500 °C of upper layer ceramsite and 420–489 mg m−3 near 1000 °C of lower layer ceramsite, respectively. NOx* emissions peak emerged in the range of 227–258 mg m−3 near 550 °C of the upper layer ceramsite, which was related to the oxidation of sulfide and the combustion of LPG. Gangue is a direct heat source for sintering of ceramsite as well. During sintering process, the heat of flue gas above and below 400 °C accounts for 55.9% and 30.0% of the all-output heat, respectively, and was potentially used for producing waste-heat steam or electricity as by-products and drying raw materials during its own initial sintering process, which can realize combined mass and heat utilization for the gangue and further reduce the cost of sintered gangue ceramsite.

Similar content being viewed by others

References

Z.Q. Hu, Q. Zhu, J.J. Xu, M.Y. Ruan, Environ. Technol. Innov. 25 (2021) 102094.

G.L. Guo, H.Z. Li, J.F. Zha, Process Saf. Environ. Protection 124 (2019) 336–344.

Z.Q. Hu, Q. Zhu, J.J. Xu, X. Zhang, Sustainability 12 (2020) 6697.

X.Y. Li, J.H. Shao, J.Q. Zheng, C.Y. Bai, X.H. Zhang, Y.J. Qiao, P. Colombo, Int. J. Appl. Ceram. Technol. (2023) https://doi.org/10.1111/ijac.14359.

X.Y. Li, Y.J. Qiao, J.H. Shao, C.Y. Bai, H.Q. Li, S. Lu, X.H. Zhang, K. Yang, P. Colombo, Ceram. Int. 48 (2022) 33914–33925.

Y.F. Li, S.H. Liu, X.M. Guan, Constr. Build. Mater. 301 (2021) 124114.

Y. Li, Y.M. Liu, Chin. J. Eng. 43 (2021) 1713–1724.

W. Zhou, Metallurgical Industry Automation 38 (2014) No. 3, 72–75.

S. Gao, S.M. Zhang, L.H. Guo, Materials 14 (2021) 6803.

N. Zhang, X.M. Liu, H.H. Sun, Metal Mine (2014) No. 3, 171–176.

X.M. Liu, B.W. Tang, H.F. Yin, M. Emile, Chin. J. Eng. 40 (2018) 438–445.

X.B. Gao, B. Jia, G. Li, X.J. Ma, Energies 15 (2022) 6718.

X.G. Cao, J.H. Fei, P. Wang, N. Li, L.L. Su, Coal Science and Technology 47 (2019) No. 4, 7–12.

J. Ma, Z.M. Yu, S.H. Shu, Z.H. Zeng, Coal Engineering 47 (2015) No. 10, 70–73.

P. Liu, F. Yan, China Mining Magazine (2008) No. 8, 49–51

X.Q. Han, M. Liu, J.J. Yan, S. Karellas, J.S. Wang, F. Xiao, Dry. Technol. 38 (2020) 1971–1987.

X. Zhu, C.A. Wang, C.L. Tang, D.F. Che, Dry. Technol. 35 (2017) 1492–1505.

X. Zhu, C.A. Wang, L.M. Wang, D.F. Che, Dry. Technol. 37 (2019) 26–37.

S.J. Hu, C.B. Man, X.Z. Gao, J.W. Zhang, X.Y. Xu, D.F. Che, Dry. Technol. 31 (2013) 1194–1205.

W.L. Wang, Z.Y. Luo, Z.L. Shi, K.F. Cen, Waste Manage. Res. 24 (2006) 207–214.

S.L. Gao, B.F. Wang, F.L. Yang, K. Zhang, F.Q. Cheng, Asia-Pacific J. Chem. Eng. 16 (2021) e2713.

F. Meng, J. Yu, A. Tahmasebi, Y. Han, Energy Fuels 27 (2013) 2923–2932.

R.K. Rathnam, L.K. Elliott, T.F. Wall, Y. Liu, B. Moghtaderi, Fuel Process. Technol. 90 (2009) 797–802.

H. Liu, R. Zailani, B.M. Gibbs, Fuel 84 (2005) 833–840.

Y.Y. Zhang, Y.X. Guo, F.Q. Cheng, K.Z. Yan, Y. Cao, Thermochim. Acta 614 (2015) 137–148.

L.H. Liu, Q.F. Liu, S. Zhang, Y.K. Li, L.T. Yang, Fuel 324 (2022) 124803.

Y.H. Liu, Study on nitrogen/sulfur occurrence pattern and its change law in coal, Xi’an Jiaotong University, Xi’an, China, 2002.

Z.B. Zhao, W. Li, B.Q. Li, CIESC Journal 54 (2003) 100–106.

B. Li, G. Chen, H. Zhang, C.D. Sheng, Fuel 118 (2014) 385–391.

J. Ren, C.J. Xie, X. Guo, Z.F. Qin, J.Y. Lin, Z. Li, Energ. Fuel. 28 (2014) 3688–3695.

Y.P. Zhao, H.Q. Hu, L.J. Jin, X.F. He, B. Wu, Fuel Process. Technol. 92 (2011) 780–786.

Q. Wang, H.G. Wang, B.Z. Sun, J.R. Bai, X.H. Guan, Fuel 88 (2009) 1520–1529.

G. Sun, H.S. Liu, Coal Processing and Comprehensive Utilization (2012) No. 3, 53–56.

Y.J. Lü, Coal 21 (2012) No. 1, 72–74.

C.L. Huo, Y.B. He, Z.H. Meng, Shanxi Coking Coal Science & Technology 35 (2011) No. 1, 47–49+52.

X.H. Yang, B. Huang, J.C. Shu, H.X. Xiong, S. Wen, X.Y. Dong, Yunnan Chemical Technology 38 (2011) No. 2, 37–40.

Y.L. Zhang, T.C. Ling, Constr. Build. Mater. 234 (2020) 117424.

B.H. Xu, Q.F. Liu, B. Ai, S.L. Ding, R.L. Frost, J. Therm. Anal. Calorim. 131 (2018) 1413–1422.

G. Habert, N. Choupay, G. Escadeillas, D. Guillaume, J.M. Montel, Appl. Clay Sci. 43 (2009) 322–330.

W.X. Li, B.F. Wang, J. Ren, K. Zhang, F.L. Yang, F.Q. Cheng, Journal of Fuel Chemistry and Technology 45 (2017) 1200–1208.

B.R. Fu, H.L. Lin, Q.S. Duan, Z. Li, Marine Electric & Electronic Engineering 32 (2012) No. S1, 38–41.

Acknowledgements

We would like to acknowledge the support of the Shendong Buertai Colliery and Shandong ECON Energy Saving Technology Co., Ltd on experiments. The financial support from the National Key R&D Program Project (Grant No. 2019YFC1905705) is greatly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that no conflicts of interest and ethical rules could have appeared to influence the work reported in this paper.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Huang, Y., Duan, Xj., Li, Y. et al. Preparation of gangue ceramsite by sintering pot test and potential analysis of waste heat recovery from flue gas. J. Iron Steel Res. Int. 30, 1401–1410 (2023). https://doi.org/10.1007/s42243-023-00993-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-023-00993-7