Abstract

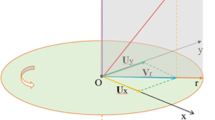

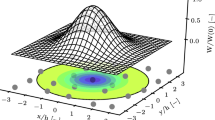

As the width–thickness ratio of the discrete nozzle atomizer's discrete hole greatly influences the loss of atomizing gas flow rate, the discrete nozzle atomizer was transformed into an annular slit atomizer with the same total nozzle outlet area. A numerical simulation study on the effect of various parameters on the atomization in the annular slit atomizer was carried out by coupling both the large eddy simulation (LES) and volume of fluid (VOF) model, which is based on the applicability of LES in capturing the breakup behavior of transient liquid droplets and the advantage of VOF method in directly capturing the phase interface. The simulation results showed that the increase in the atomization pressure makes the gas gain higher momentum, while the increase in the nozzle intersection angle decreases the distance between the nozzle exit and the computational domain axis. The increase in these two variables results in enhancing the gas–liquid interaction in the primary atomization zone and the formation of more aluminum droplets simultaneously. It is considered that the atomization effect becomes better when atomization pressure is 2.5 MPa, and the nozzle intersection angle is 60°. Industrial tests showed that the aluminum powder prepared by the optimized annular slit atomizer has a finer mean particle size and a higher yield of fine powder. The numerical simulation results agree well with the industrial test data of the powder particle size.

Similar content being viewed by others

References

W.E. Frazier, J. Mater. Eng. Perform. 23 (2014) 1917–1928. https://doi.org/10.1007/s11665-014-0958-z.

S. González, F. Cáceres, V. Fox, R.M. Souto, Prog. Org. Coat. 46 (2003) 317–323. https://doi.org/10.1016/s0300-9440(03)00021-3.

L. Galfetti, L.T. De Luca, F. Severini, L. Meda, G. Marra, M. Marchetti, M. Regi, S. Bellucci, J. Phys.: Condens. Matter 18 (2006) S1991. https://doi.org/10.1088/0953-8984/18/33/s15.

J.X. Xu, C.Y. Chen, L.Y. Shen, W.D. Xuan, X.G. Li, S.S. Shuai, X. Li, T. Hu, C.J. Li, J.B. Yu, J. Wang, Z.M. Ren, Acta Phys. Sin. 70 (2021) 140201. https://doi.org/10.7498/aps.70.20202071.

J.Q. Liu, J. Pang, P. Wang, D. Yang, X.Y. Li, J.Q. Zhang, China Metallurgy 32 (2022) No. 2, 1–14. https://doi.org/10.13228/j.boyuan.issn1006-9356.20210531.

I.E. Anderson, E.M.H. White, R. Dehoff, Curr. Opin. Solid State Mater. Sci. 22 (2018) 8–15. https://doi.org/10.1016/j.cossms.2018.01.002.

K.H. Arachchilage, M. Haghshenas, S. Park, L. Zhou, Y. Sohn, B. McWilliams, K. Cho, R. Kumar, Adv. Powder Technol. 30 (2019) 2726–2732. https://doi.org/10.1016/j.apt.2019.08.019.

J. Zhou, Study on desulphurization process by spraying powder at the bottom of furnace, Metallurgical Industry Press, Beijing, China, 2008.

G. Antipas, Metals 2 (2012) 202–210. https://doi.org/10.3390/met2020202.

F. Hernandez, T. Riedemann, J. Tiarks, B. Kong, J.D. Regele, T. Ward, I.E. Anderson, in: TMS 2019 148th Annual Meeting & Exhibition Supplemental Proceedings, The Minerals, Metals & Materials Series, Springer, Berlin, Germany, 2019, pp. 1507–1519. https://doi.org/10.1007/978-3-030-05861-6_143.

D.A. Firmansyah, R. Kaiser, R. Zahaf, Z. Coker, T.Y. Choi, D. Lee, Jpn. J. Appl. Phys. 53 (2014) 05HA09. https://doi.org/10.7567/jjap.53.05ha09.

O. Aydin, R. Unal, Comput. Fluids 42 (2011) 37–43. https://doi.org/10.1016/j.compfluid.2010.10.013.

M. Tong, D.J. Browne, Comput. Fluids 38 (2009) 1183–1190. https://doi.org/10.1016/j.compfluid.2008.11.014.

J. Ting, I.E. Anderson, Mater. Sci. Eng. A 379 (2004) 264–276. https://doi.org/10.1016/j.msea.2004.02.065.

N. Zeoli, S. Gu, Comput. Mater. Sci. 43 (2008) 268–278. https://doi.org/10.1016/j.commatsci.2007.10.005.

J.S. Thompson, O. Hassan, S.A. Rolland, J. Sienz, Powder Technol. 291 (2016) 75–85. https://doi.org/10.1016/j.powtec.2015.12.001.

X. Li, L. Heisteruber, L. Achelis, V. Uhlenwinkel, U. Fritsching, At. Sprays 21 (2011) 933–948. https://doi.org/10.1615/AtomizSpr.2012004487.

J.Q. Liu, Y.N. Dong, P. Wang, H. Zhao, J. Pang, X.Y. Li, J.Q. Zhang, J. Iron Steel Res. Int. (2022) https://doi.org/10.1007/s42243-022-00855-8.

P.J. O'Rourke, A.A. Amsden, The TAB method for numerical calculation of spray droplet breakup, Los Alamos National Laboratory, Los Alamos, USA, 1987.

R. Reitz, Atomisation Spray Technol. 3 (1987) 309–337.

A. Hillier, H. Isobe, K. Shibata, T. Berger, ApJL 736 (2011) L1. https://doi.org/10.1088/2041-8205/736/1/l1.

X. Li, U. Fritsching, J. Mater. Process. Technol. 239 (2017) 1–17. https://doi.org/10.1016/j.jmatprotec.2016.08.009.

N. Zeoli, H. Tabbara, S. Gu, Chem. Eng. Sci. 66 (2011) 6498–6504. https://doi.org/10.1016/j.ces.2011.09.014.

J.U. Brackbill, D.B. Kothe, C. Zemach, J. Comput. Phys. 100 (1992) 335–354. https://doi.org/10.1016/0021-9991(92)90240-Y.

Z.Q. Liu, Multi-scale modeling of multiphase and inhomogeneous transmission mechanisms in continuous casting mold, Northeastern University, Shenyang, China, 2015.

J. Smagorinsky, Mon. Weather Rev. 91 (1963) 99–164. https://doi.org/10.1175/1520-0493(1963)091<0099:GCEWTP>2.3.CO;2.

C.W. Hirt, B.D. Nichols, J. Comput. Phys. 39 (1981) 201–225. https://doi.org/10.1016/0021-9991(81)90145-5.

X.H. Song, X.Y. Lv, S.S. Xie, Production technology of aluminum and aluminum alloy powder, Metallurgical Industry Press, Beijing, China, 2008.

M. Ishii, T. Hibiki, Thermo-fluid dynamics of two-phase flow, 2nd Ed., Springer, Berlin, Germany, 2011. https://doi.org/10.1007/978-1-4419-7985-8.

W.R. Case, The experimental analysis and simulation of the breakup of a liquid filament jetting from a rotary laminar spray nozzle, ETH Zurich, Zurich, Switzerland, 2016. https://doi.org/10.3929/ethz-a-010870075.

J.L. York, H.F. Stubbs, M.R. Tek, Trans. ASME 75 (1953) 1279–1286. https://doi.org/10.1115/1.4015594.

Acknowledgements

The authors would like to express their gratitude for the financial support provided by the National Natural Science Foundation of China (U21A20317) and gratitude to EditSprings (https://www.editsprings.cn) for the expert linguistic services provided. In addition, numerical calculation is supported by High-Performance Computing Center of Wuhan University of Science and Technology.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Y., Dang, Yc., Chen, Xq. et al. Numerical simulation of effect of various parameters on atomization in an annular slit atomizer. J. Iron Steel Res. Int. 30, 1128–1141 (2023). https://doi.org/10.1007/s42243-023-00943-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-023-00943-3