Abstract

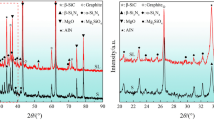

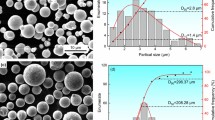

MgO–C refractories with stainless steel fibers were prepared to investigate the effects of stainless steel fibers addition on the thermal shock resistance, oxidation resistance, and microstructure of MgO–C refractories, and the optimum amount of stainless steel fibers was determined. The results showed that adding stainless steel fiber in MgO–C refractories can increase flexural strength and thermal shock resistance, with an optimal addition of 2 wt.%, owing to the bridging effect and crack deflection toughening of stainless steel fibers inside the material. The formation of MgAl1.9Fe0.1O4 composite spinel, which was responsible for higher oxidation resistance, produced volume expansion and prevented the diffusion of oxygen. The strengthening mechanism is physical embedding at room temperature, while it is reaction bonding at high temperature.

Similar content being viewed by others

References

L. Redecker, A. Sax, P. Quirmbach, H. Jansen, J. Am. Ceram. Soc. 99 (2016) 3761–3769. https://doi.org/10.1111/jace.14380.

L. Musante, L.F. Martorello, P.G. Galliano, A.L. Cavalieri, A.G. Tomba Martinez, Ceram. Int. 38 (2012) 4035–4047. https://doi.org/10.1016/j.ceramint.2012.01.062.

K.S. Lee, G.H. Jo, Y.G. Jung, Y. Byeun, Ceram. Int. 42 (2016) 9955–9962. https://doi.org/10.1016/j.ceramint.2016.03.097.

S. Hayashi, H. Takahashi, A. Watanabe, A. Osaka, Y. Miura, J. Ceram. Soc. Jpn. 102 (1994) 23–28. https://doi.org/10.2109/jcersj.102.23.

M. Bag, S. Adak, R. Sarkar, Ceram. Int. 38 (2012) 2339–2346. https://doi.org/10.1016/j.ceramint.2011.10.086.

E.M.M. Ewais, J. Ceram. Soc. Jpn. 112 (2004) 517–532. https://doi.org/10.2109/jcersj.112.517.

A.P. Luz, D.O. Vivaldini, F. López, P.O.R.C. Brant, V.C. Pandolfelli, Ceram. Int. 39 (2013) 8079–8085. https://doi.org/10.1016/j.ceramint.2013.03.080.

B. Liu, J.L. Sun, G.S. Tang, K.Q. Liu, L. Li, Y.F. Liu, J. Iron Steel Res. Int. 17 (2010) 75–78. https://doi.org/10.1016/S1006-706X(10)60187-2.

C. Yu, B. Dong, Y.F. Chen, B.Y. Ma, J. Ding, C.J. Deng, H.X. Zhu, J.H. Di, J. Iron Steel Res. Int. 29 (2022) 1052–1062. https://doi.org/10.1007/s42243-022-00804-5.

T.B. Zhu, Y.W. Li, S.B. Sang, S.L. Jin, Y.B. Li, L. Zhao, X. Liang, Ceram. Int. 40 (2014) 4333–4340. https://doi.org/10.1016/j.ceramint.2013.08.101.

M. Bag, S. Adak, R. Sarkar, Ceram. Int. 38 (2012) 4909–4914. https://doi.org/10.1016/j.ceramint.2012.02.082.

M. Chen, S. Gao, L. Xu, N. Wang, Ceram. Int. 45 (2019) 21023–21028. https://doi.org/10.1016/j.ceramint.2019.06.306.

H. Rastegar, M. Bavand-Vandchali, A. Nemati, F. Golestani-Fard, Ceram. Int. 45 (2019) 3390–3406. https://doi.org/10.1016/j.ceramint.2018.10.253.

T. Bahtli, D.Y. Hopa, V.M. Bostanci, N.S. Ulvan, S.Y. Yasti, Ceram. Int. 44 (2018) 6780–6785. https://doi.org/10.1016/j.ceramint.2018.01.097.

K.S. Campos, G.F.B.L. e Silva, E.H.M. Nunes, W.L. Vasconcelos, Ceram Int. 38 (2012) 5661–5667. https://doi.org/10.1016/j.ceramint.2012.04.009.

C. Yu, H.X. Zhu, W.J. Yuan, C.J. Deng, P. Cui, S.M. Zhou, J. Alloy. Compd. 579 (2013) 348–354. https://doi.org/10.1016/j.jallcom.2013.06.088.

G.R. Liu, L.A. Chen, H.L. Zhao, Bull. Chin. Ceram. Soc. 8 (1989) 22–28. https://doi.org/10.16552/j.cnki.issn1001-1625.1989.04.005.

C.M. Peret, V.C. Pandolfelli, Am. Ceram. Soc. Bull. 85 (2006) 9401–9407. https://doi.org/10.1590/S0366-69132005000100002.

G.R. Liu, Bull. Chin. Ceram. Soc. 16 (1997) 55–61. https://doi.org/10.16552/j.cnki.issn1001-1625.1997.01.011.

C.H. Sump, J. Mater. Energy Syst. 6 (1985) 279–286. https://doi.org/10.1007/BF02833517.

S.N. Laha, Trans. Indian Ceram. Soc. 39 (1980) 131–137. https://doi.org/10.1080/0371750X.1980.10840735.

W.G. Bareiro, F. de Andrade Silva, E.D. Sotelino, Constr. Build. Mater. 240 (2020) 117881. https://doi.org/10.1016/j.conbuildmat.2019.117881.

K.X. Ni, M.J. Zhang, H.Z. Gu, A. Huang, H.M. Li, Z.J. Shao, Refractories 50 (2016) 10–15. https://doi.org/10.3969/j.issn.1001-1935.2016.01.003.

Y. Sun, D.M. Zhang, Y. Zhou, Q. Fu, J. Kumming Univ. Sci. Technol. 22 (1997) 154–158. https://doi.org/10.16112/j.cnki.53-1223/n.1997.01.032.

W.B. Wang, Refractory technology, 2nd ed., Metallurgical Industry Press, Beijing, China, 2007.

H. Jansen, Ironmak. Steelmak. 34 (2007) 384–388. https://doi.org/10.1179/174328107X225134.

S.M. Kumar, H. Jansen, H. Bunse, R. Gaebel, J. Schlüter, J. Rzepczyk, Stahl Eisen. 126 (2006) 33–36.

Y.X. Dai, J. Li, W. Yan, C.B. Shi, J. Mater. Res. Technol. 9 (2020) 4292–4308. https://doi.org/10.1016/j.jmrt.2020.02.055.

J.Z. Shang, B.L. Liu, K. Shi, X.Y. Han, Y. Xia, Y. Liu, J. Mater. Sci. 57 (2022) 17172–17187. https://doi.org/10.1007/s10853-022-07687-7.

S. Zhang, N.J. Marriott, W.E. Lee, J. Eur. Ceram. Soc. 21 (2001) 1037–1047. https://doi.org/10.1016/S0955-2219(00)00308-3.

H.S. Tripathi, A. Ghosh, Ceram. Int. 36 (2010) 1189–1192. https://doi.org/10.1016/j.ceramint.2009.12.011.

X.Y. Han, K. Shi, S.H. Ma, Y. Xia, Y. Liu, J.Z. Shang, , Ceram. Int. 48 (2022) 4576–4583. https://doi.org/10.1016/j.ceramint.2021.10.244.

Acknowledgements

This work was supported by the Scientific and Technological Research Project of the Henan Provincial Department of Science and Technology of China (No. 212102210579).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors of this article have no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shang, Jz., Liu, Bl., Shi, K. et al. Effect of stainless steel fibers on properties of MgO–C refractories. J. Iron Steel Res. Int. 30, 2186–2193 (2023). https://doi.org/10.1007/s42243-023-00938-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-023-00938-0