Abstract

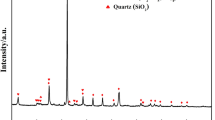

The use of low-grade, refractory and composite paragenetic mineral resources is necessary for overcoming the shortage of iron ore resources in China. As a solution to the treatment of such iron ores, the direct reduction of carbon-bearing pellets can ensure complete iron removal and the effective enrichment of other high-value elements. Thus, this technology enjoys a broad application prospect. However, there are several problems with low-temperature reduction, such as low iron ore reaction efficiency, long reaction time, and high energy consumption. To improve the low-temperature carbothermic reduction efficiency of iron ores, a static magnetic field with magnetic induction intensity of 1.0 T was introduced. An isothermal reduction experiment was conducted at 1223 K to study the low-temperature self-reduction characteristics of carbon-bearing pellets of Bayan Obo lean iron ores in the static magnetic field. Also, the acting mechanism of the magnetic field was explored from the perspective of the reduction process, reaction efficiency, phase composition, microstructure changes, and dynamic behavior of iron ores. The results showed that the magnetic field can increase the low-temperature reduction rate of carbon-bearing pellets of Bayan Obo lean iron ores. Under the conditions of reduction temperature of 1223 K, magnetic induction intensity of 1.0 T, and reduction time of 60 min, the reduction degree was 92.42%, 1.65 times that without a magnetic field. The magnetic field promoted the replacement of Ca2+ and Fe2+, so that the hard-to-reduce iron-bearing silicates were reduced in the order of Fe2SiO4 → (Ca, Na)FeSiO4 → FeO → Fe. The magnetic field enabled loose minerals, more pores and cracks, and changes in the growth morphology and distribution position of metallic iron. Compared with the case under the non-magnetic condition, the metallic iron precipitated from the slag phase in a foliated shape, separated from the matrix iron oxides, and grew up at the junction of the slag phase and coke. The magnetic field significantly increased the interfacial chemical reaction rate of the carbothermic reduction of iron ores and reduced the internal diffusion resistance of gas in the product layer. Specifically, the interfacial chemical reaction rate increased by 138% and the internal diffusion coefficient increased by 309%. Therefore, the effect of the magnetic field on the internal diffusion resistance was the main cause for strengthening the low-temperature reduction of iron ores.

Similar content being viewed by others

References

G.X. Ren, S.W. Xiao, J.L. Li, Z.Y. Peng, M.J. Ran, W. Chen, Mining and Metallurgical Engineering 41 (2021) No. 4, 79–83.

Y. Zhou, J.X. Liu, G.J. Cheng, X.X. Xue, H. Yang, Sep. Purif. Technol. 271 (2021) 118742.

K.Y. Wang, J.E. Zhang, A.M. Fang, C. Dong, F.Y. Hu, Acta Petrologica Sin. 34 (2018) 785–798.

Z.F. Yang, Z.H. Zhu, Z.J. Wang, Q. Li, X.B. Huang, S.H. Wang, Journal of the Chinese Society of Rare Earths 37 (2019) 769–776.

C.Q. Li, Multipurpose Utilization of Mineral Resources 2 (1981) No. 1, 13–15.

J. Yang, T. Jiang, S.H. Ma, S.T. Yang, M. Zhou, J. Iron Steel Res. Int. 29 (2022) 1723–1733.

C. Geng, T.C. Sun, Y.W. Ma, C.Y. Xu, H.F. Yang, J. Iron Steel Res. Int. 24 (2017) 156–164.

X.H. Li, J. Kou, T.C. Sun, X.S. Guo, Y.C. Tian, Miner. Process. Extr. Metall. Rev. 42 (2021) 115–122.

S.C. Wu, Z.Y. Li, T.C. Sun, X.H. Li, Y. Cheng, J. Cent. South Univ. 29 (2022) 443–454.

S. Yuan, Z.K. Liu, J.Q. Liu, Q. Wang, Materials China 38 (2019) 759–767.

Z.M. Ren, Z.S. Lei, C.J. Li, W.D. Xuan, Y.B. Zhong, X. Li, Acta Metall. Sin. 56 (2020) 583–600.

T. Inomoto, Y. Ogawa, T. Toh, J. Iron Steel Inst. Jpn. 43 (2003) 828–835.

T.X. Zheng, Study of microstructure evolution during solidification process of Zn-Bi immiscible alloys by superimposing static magnetic fields, Shanghai University, Shanghai, China, 2016.

T.S. Qiu, S.H. Xiong, Q. Xia, Metal Mine (2004) No. 12, 32–34.

X.C. Li, T.X. Wang, X. Jiang, B.Q. Zhu, Journal of the Chinese Ceramic Society 39 (2011) 452–457.

A.S. Shigarev, L.P. Dmitrieva, Met. Sci. Heat Treat. 20 (1978) 213–217.

X.D. Zhang, Y.L. Jin, Iron Steel Vanadium Titanium 42 (2021) No. 2, 139–145.

Y.L. Jin, F.T. Han, H. Yu, Z.W. Zhao, J.Y. Zhang, Iron Steel Vanadium Titanium 39 (2018) No. 6, 103–109.

S.R. Na, Discrimination of ironmaking calculation, Metallurgical Industry Press, Beijing, China, 2010.

X.G. Huang, Ferrous metallurgy theory, Metallurgical Industry Press, Beijing, China, 2020.

P.M. Guo, P. Zhao, Theory and technology for fast metallurgy at low temperature, Metallurgical Industry Press, Beijing, China, 2020.

Y.L. Jin, H. Yu, J.Y. Zhang, Z.W. Zhao, Acta Metall. Sin. 55 (2019) 410–416.

J.Y. Zhang, Metallurgy physical chemistry, Metallurgical Industry Press, Beijing, China, 2004.

Acknowledgements

The authors are grateful for the financial support from the Natural Science Foundation of Inner Mongolia (2019MS05010) and the National Natural Science Foundation of China (51464039 and 52064044).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare that none of the authors has any financial or scientific conflicts of interest with regard to the research described in this manuscript.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jin, Yl., Jiang, Jt., Dai, Hx. et al. Reaction characteristics of carbon-bearing pellets of Bayan Obo lean iron ores in a static magnetic field. J. Iron Steel Res. Int. 30, 1687–1700 (2023). https://doi.org/10.1007/s42243-023-00912-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-023-00912-w