Abstract

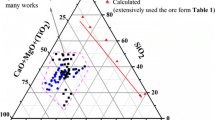

The effects of MgO/Al2O3 and CaO/SiO2 ratios on the viscosity, break-point temperature, and viscous activation energy of a high titanium-bearing slag were studied. The results showed that both the viscosity and the break-point temperature of the slag decreased with the MgO/Al2O3 ratio increasing from 0.50 to 0.65, the viscous activation energy decreased gradually, and the thermal stability became better. In addition, with an increase in CaO/SiO2 ratio from 1.12 to 1.22, the main viscous units in the slag depolymerized and the viscosity of slag decreased. However, the break-point temperature of slag showed an increasing tendency. The viscous activation energy decreased gradually and the thermal stability became better. The basic phase in the experimental high titanium-bearing slag was pyroxene, and its amount increased with increasing the MgO/Al2O3 ratio while decreased with increasing the CaO/SiO2 ratio.

Similar content being viewed by others

References

G.B. Qiu, L. Chen, J.Y. Zhu, X.W. Lv, C.G. Bai, ISIJ Int. 55 (2015) 1367–1376.

R.Z. Xu, J.L. Zhang, Z.Y. Wang, K.X. Jiao, Steel Res. Int. 88 (2017) 1600241.

C. Lv, K. Yang, S.M. Wen, S.J. Bai, Q.C. Feng, JOM 69 (2017) 1801–1805.

C. Feng, M.S. Chu, J. Tang, Z.G. Liu, Int. J. Miner. Metall. Mater. 25 (2018) 609–622.

J. Tang, M.S. Chu, F. Li, C. Feng, Z.G. Liu, Y.S. Zhou, Int. J. Miner. Metall. Mater. 27 (2020) 713–714.

C. Feng, M.S. Chu, J. Tang, Y.T. Tang, Z.G. Liu, Steel Res. Int. 87 (2016) 1274–1283.

S. Wang, Y.F. Guo, T. Jiang, F. Chen, F.Q. Zheng, L.Z. Yang, M.J. Tang, JOM 71 (2019) 323–328.

R.Z. Xu, J.L. Zhang, X.Y. Fan, W.W. Zheng, Y.A. Zhao, ISIJ Int. 57 (2017) 1887–1894.

C.Y. Xu, C. Wang, R.Z. Xu, J.L. Zhang, K.X. Jiao, Int. J. Miner. Metall. Mater. 28 (2021) 797–803.

T. Hu, X.W. Lv, C.G. Bai, Steel Res. Int. 87 (2016) 494–500.

E.H. Wu, R. Zhu, S.L. Yang, L. Ma, J. Li, J. Hou, J. Iron Steel Res. Int. 23 (2016) 655–660.

Y.R. Liu, J.L. Zhang, Z.J. Liu, X.D. Xing, Int. J. Miner. Metall. Mater. 23 (2016) 760–768.

Y.M. Gao, S.B. Wang, C. Hong, X.J. Ma, F. Yang, Int. J. Miner. Metall. Mater. 21 (2014) 353–362.

J. Ma, G.Q. Fu, W. Li, M.Y. Zhu, Int. J. Miner. Metall. Mater. 27 (2020) 310–318.

C.B. Shi, D.L. Zheng, S.H. Shin, J. Li, J.W. Cho, Int. J. Miner. Metall. Mater. 24 (2017) 18–24.

Y.H. Gao, L.T. Bian, Z.Y. Liang, Steel Res. Int. 86 (2015) 386–390.

L.B. Deng, X.F. Zhang, M.X. Zhang, X.L. Jia, J. Non-Cryst. Solids 500 (2018) 310–316.

Y. Li, H.Y. Yu, Z.T. Zhang, M. Zhang, M. Guo. ISIJ Int. 55 (2015) 134–141.

Z.Y. Chang, K.X. Jiao, J.L. Zhang, X.J. Ning, Z.Q. Liu, ISIJ Int. 58 (2018) 2173–2179.

W. Li, G.Q. Fu, M.S. Chu, M.Y. Zhu, Steel Res. Int. 88 (2017) 1600120.

X. Jiang, H.Y. Zhang, H.Y. Zheng, Q.J. Gao, F.M. Shen, J. Iron Steel Res. Int. 27 (2020) 624–630.

X.F. Zhang, T. Jiang, X.X. Xue, B.S. Hu, Steel Res. Int. 87 (2016) 87–94.

C. Feng, M.S. Chu, J. Tang, J. Qin, F. Li, Z.G. Liu, Int. J. Miner. Metall. Mater. 23 (2016) 868–880.

L. Yao, S. Ren, X.Q. Wang, Q.C. Liu, L.Y. Dong, J.F. Yang, J.B. Liu, Steel Res. Int. 87 (2016) 241–249.

Z.N. Jin, H.Y. Yang, J.F. Lv, L.L. Tong, G.B. Chen, Q. Zhang, JOM 70 (2018) 1430.

J.B. Kim, I. Sohn, ISIJ Int. 54 (2014) 2050–2058.

C. Feng, J. Tang, L.H. Gao, Z.G. Liu, M.S. Chu, ISIJ Int. 59 (2019) 31–38.

K. Hu, X.W. Lv, S.P. Li, W. Lv, B. Song, K.X. Han, Metall. Mater. Trans. B 49 (2018) 1963–1973.

S. Wang, Y.F. Guo, T. Jiang, F. Chen, F.Q. Zheng, M.J. Tang, L.Z. Yang, G.Z. Qiu, Trans. Nonferrous Met. Soc. China 28 (2018) 2528–2537.

C. Feng, L.H. Gao, J. Tang, Z.G. Liu, M.S. Chu, Trans. Nonferrous Met. Soc. China 30 (2020) 800–811.

Acknowledgements

The authors were specially grateful to the National Natural Science Foundation of China (Grant No. 51904063) and the Fundamental Research Funds for the Central Universities (N2025023).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gao, Hb., Tang, J., Chu, Ms. et al. Effects of MgO/Al2O3 and CaO/SiO2 ratios on viscosity of high titanium-bearing blast furnace slag. J. Iron Steel Res. Int. 30, 456–464 (2023). https://doi.org/10.1007/s42243-022-00876-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-022-00876-3