Abstract

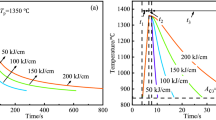

The effects of Ca treatment on the particle, microstructure, and toughness of heat-affected zone (HAZ) of shipbuilding steel with Zr–Ti deoxidation after high-heat-input welding were investigated. The simulated welding at a high-heat-input welding of 200 kJ/cm was carried out using Gleeble-3800 welding simulation. Then, particle characteristics were characterized using an Aztec-Feature automatic particle analysis system. Additionally, an in-situ observation experiment was performed to study the relationships between particle and microstructure by high-temperature confocal laser scanning microscopy (HT-CLSM). The results indicated that the average HAZ toughness at −40 °C was increased from 183 to 290 J by adding 0.0026 wt.% Ca. Meanwhile, the formation of acicular ferrite ratio was increased from 49.34% to 60.28% due to the addition of Ca. The scanning electron microscopy results clearly showed that CaO–Al2O3–TiOx–ZrO2–MnS particles could act as effective nucleation sites for the formation of acicular ferrite, which has been verified by the observation of the particle–microstructure relationship under HT-CLSM. Furthermore, particle characterization results show that the cumulative frequency of particles with the size of 1–3 μm was 33.2% in HAZ of Zr–Ti shipbuilding steel but 66.2% in HAZ of Zr–Ti–Ca shipbuilding steel.

Similar content being viewed by others

References

Y. Wang, L.G. Zhu, Q.J. Zhang, C.J. Zhang, S.M. Wang, Metals 8 (2018) 616.

X.D. Zou, J.C. Sun, D.P. Zhao, H. Matsuura, C. Wang, J. Iron Steel Res. Int. 25 (2018) 164–172.

X. Liu, J. Iron Steel Res. Int. 18 (2011) No. 1, 1–7.

Q.Y. Wang, X.D. Zou, H. Matsuura, C. Wang, Metall. Mater. Trans. B 49 (2018) 18–22.

T.M.D. Borva, W.D. Flores, L.O. Turani, R.C. Junior, Weld. Int. 31 (2017) 184–195.

Y. Tomita, N. Saito, T. Tsuzuki, Y. Tokunaga, K. Okamoto, ISIJ Int. 34 (1994) 829–835.

F.M. Song, Z.G. Li, Y.H. Qian, K. Shen, Hot Work Technol. 35 (2006) No. 5, 69–75.

J.I. Takamura, S. Mizoguchi, in: Proceedings of the 6th International Iron and Steel Congress, The Japan Institute of Metals and Materials, Nagoya, Japan, 1990, pp. 56–70.

T. Furuhara, T. Shinyoshi, G. Miyamoto, J. Yamaguchi, N. Sugita, N. Kimura, N. Takemura, T. Maki, ISIJ Int. 43 (2003) 2028–2037.

Z.Z. Liu, Y.S. Sang, Steelmaking 23 (2007) No. 4, 1–10.

J. Yang, C.F. Li, W.Z. Shen, Heat Treatment of Metals 38 (2013) No. 2, 21–29.

R. Wei, K.M. Wu, H.H. Wang, Y.K. Yao, D.Y. Wang, L.D. Meng, Transactions of the China Welding Institution 33 (2012) No. 10, 71–76.

A. Kojima, A. Kiyose, R. Uemori, M. Minagawa, M. Hoshino, T. Nakashima, K. Ishida, H. Yasui, Nippon Steel Tech. Rep. 90 (2004) 2–5.

A. Kojima, K.I. Yoshii, T. Hada, O. Saeki, K. Ichikawa, Y. Yoshida, Y. Shimura, K. Azuma, Nippon Steel Tech. Rep. 90 (2004) 33–37.

J.L. Lee, Y.T. Pan, ISIJ Int. 35 (1995) 1027–1033.

Z.L. Feng, Welding Research Abroad 42 (1996) 340–349.

W.G. Zhao, W. Wang, S.H. Chen, J.B. Qu, Mater. Sci. Eng. A 528 (2011) 7417–7422.

H.N. Lou, C. Wang, B.X. Wang, Z.D. Wang, Y.Q. Li, Z.G. Chen, Metals 8 (2018) 534.

Y.M. Kim, H. Lee, N.J. Kim, Mater. Sci. Eng. A 478 (2008) 361–370.

H.K. Sung, S.Y. Shin, W. Cha, K. Oh, S. Lee, N.J. Kim, Mater. Sci. Eng. A 528 (2011) 3350–3357.

K. Zhu, Z. Yang, Metall. Mater. Trans. A 42 (2011) 2207–2213.

J.H. Shim, Y.J. Oh, Y.W. Suh, J.D. Shim, J.S. Byun, D.N. Lee, Acta Mater. 49 (2001) 2115–2122.

J.S. Byun, J.H. Shim, Y.W. Cho, D.N. Lee, Acta Mater. 51 (2003) 1593–1606.

A.R. Mills, G. Thewlis, J.A. Whiteman, Mater. Sci. Technol. 3 (1987) 1051–1061.

H. Goto, K.I. Miyazawa, W. Yamada, K. Tanaka, ISIJ Int. 35 (1995) 708–714.

Y.W. Cho, J.S. Byun, J.M. Shim, Mater. Sci. Forum 426-4 (2003) 1511–1516.

J.S. Byun, J.H. Shim, Y.W. Cho, Scripta Mater. 48 (2003) 449–454.

K. Yamamoto, T. Hasegawa, J.I. Takamura, ISIJ Int. 36 (1996) 80–86.

G. Shiesato, M. Sugiyama, S. Aihara, R. Uemori, Y. Tomita, Tetsu-to-Hagane 87 (2001) 93–100.

X.D. Zou, J.C. Sun, H. Matsuura, C. Wang, Metall. Mater. Trans. A 50 (2019) 4506–4512.

S. Kanazawa, A. Nakashima, K. Okamoto, K. Kanaya, Tetsu-to-Hagane 61 (1975) 2589–2603.

Acknowledgements

This study was supported by the Open Project Program of Beijing Key Laboratory of Pipeline Critical Technology and Equipment for Deepwater Oil & Gas Development (Grant No. BIPT2019001) and the Natural Science Foundation of Hebei Province (Grant No. E2021318004). The authors would like to express sincere thanks to Dr. Yang He and Dr. Jie Zhang of University of Science and Technology Beijing, China for their careful revision of this paper.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Liu, Hb., Kang, J., Zhao, Xj. et al. Influence of Ca treatment on particle–microstructure relationship in heat-affected zone of shipbuilding steel with Zr–Ti deoxidation after high-heat-input welding. J. Iron Steel Res. Int. 29, 1291–1298 (2022). https://doi.org/10.1007/s42243-022-00791-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-022-00791-7