Abstract

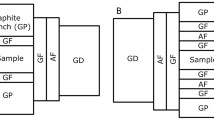

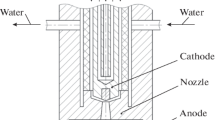

The world’s first three-graphite electrode direct current (DC) plasma heating system (2500 kW) was successfully put into production on the 50-t tundish of a two-strand slab caster. The single metallic torch plasma tundish heaters were reviewed. In addition, the induction heating system was also estimated. The three-graphite electrode DC plasma tundish heating (PTH) system does not require any electrode to be fitted to the tundish. Five electrodes can be used to realize uniform and fast heating of the six-strand tundish. Heating with high power can effectively eliminate the steep temperature drop of the molten steel in the tundish during ladle change-over. The system has turned out to be very reliable, simple, and maintenance-free. The heating rate is high within 0.5 to 2.0 °C/min. Some heats with ultra-low superheat (2.6–11.0 °C) were observed, and the molten steels were successfully cast by the powerful heating capacity and good control performance of the system in the practical production. It can be concluded that continuous casting with superheat of 5–10 °C in the tundish was fully realistic with PTH.

Similar content being viewed by others

References

S. Yogeshwar, Metall. Mater. Trans. B 47 (2016) 2095–2106.

P. Hong, Appl. Mech. Mater. 217 (2012) 2519–2522.

G.A. Filippov, A.S. Tyuftyaev, M.Kh. Gadzhiev, D.I. Yusupov, M.A. Sargsyan, Metallurgist 60 (2016) 267–273.

K. Setsuo, S. Wakida, T. Kanki, T. Hosokawa, Nippon steel Tech. Rep. Overseas 85 (2002) 162–166.

V. Ludlow, A. Normanton, A. Anderson, M. Thiele, J. Ciriza, J. Laraudogoitia, W. van der Knoop, Ironmak. Steelmak. 32 (2005) 68–74.

A. Shiraishi, K. Iwata, H. Tomono, H. Nagahata, A. Mori, Rev. Metall. 87 (1990) 777–784.

S. Tao, H.J. Wu, C. Guo, Y. Li, Z.C. Ma, J. Iron Steel Res. Int. 23 (2016) 329–337.

J.Y. Park, K.H. Oh, H.Y. Ra, ISIJ Int. 41 (2001) 70–75.

M.M. Haque, A.F. Ismail, J. Mater. Process. Technol. 162 (2005) 312–316.

Y.A. Pak, G.A. Filippov, D.I. Yusxupov, A.S. Tyuftyaev, M.E. Isakaev, B.A. Sarychev, Metallurgist 58 (2014) 672–676.

E.Kh. Isakaev, A.S. Tyuftyaev, G.A. Filippov, D.I. Yusupov, Steel in Translation 44 (2014) 665–668.

A.F. Ferreira, W.B. Chrisóstimo, R.C. Sales, W.J.L. Garção, N. de Paula Sousa, Int. J. Adv. Manuf. Technol. 104 (2019) 957–965.

S.K. Choudhary, S. Ganguly, ISIJ Int. 47 (2007) 1759–1766.

Q.W. Zuo, X. An, J.B. Yang, D.Q. Cang, Adv. Mater. Res. 997 (2014) 534–537.

O. Bode, K. Schwerdtfeger, H.G. Geck, F. Höfer, Ironmak. Steelmak. 35 (2008) 137–145.

W. Liang, T.N. Mustoe, Steel Times 226 (1998) CC2–CC4.

S. Kittaka, T. Sato, S. Wakida, M. Miyashita, Nippon Steel Tech. Rep. 92 (2005) 16–21.

C. Yao, M. Wang, M.X. Pan, Y.P. Bao, J. Iron Steel Res. Int. 28 (2021) 1114–1124.

X. Huang, B.G. Thomas, F.M. Najjar, Metall. Mater. Trans. B 23 (1992) 339–356.

B. Yang, A.Y. Deng, P.F. Duan, X.L. Kang, E.G. Wang, J. Iron Steel Res. Int. 29 (2022) 151–164.

G.N. Okorokov, A.I. Donets, A.Z. Shevtsov, V.A. Sinelnikov, P.I. Yugov, B.F. Zinko, M.M. Krutyanskii, A.M. Popov, Metallurgist 42 (1998) 15–20.

H.J Bebber, Steel Times 218 (1990) 244–245.

C. Moore, C.P. Heanley, P.M. Cowx, Steel Times Int. 13 (1989) 44–46.

C. Wang, Study on plasma heating in tundish and nitrogen content in steel, University of Science and Technology Beijing, Beijing, China, 1995.

C. Wang, G.P. Pan, C.Z. Yang, J. Zhang, P. Zhao, Iron and Steel 32 (1997) No. 9, 21–24.

E.Kh. Isakaev, A.S. Tyuftyaev, G.A. Filippov, D.I. Yusupov, Metallurgist 57 (2013) 427–433.

C. Wang, G.P. Pan, J. Zhang, in: 81th Steelmaking Conference Proceedings, Iron and Steel Society of AIME, Toronto, Canada, 1998, pp. 105–112.

H. Bebber, K. Alexander, Steel Res. 72 (2001) 460–465.

Q. Wang, M.Y. Shi, Y.M. Li, B.K. Li, Journal of Northeastern University (Natural Science) 35 (2014) 1442–1446.

H.Y. Tang, K.M. Wang, X.S. Li, J.W. Liu, J.Q. Zhang, Metals 11 (2021) 1075.

E. Abiona, H.L. Yang, R. Chaudhary, R.K. Kandasamy, J.E. Eriksson, in: 8th International Conference on Electromagnetic Processing of Materials, Cannes, France, 2015, pp. 1–5.

M.J. Zhao, Y. Wang, S.F. Yang, J.S. Li, W. Liu, Z.Q. Song, J. Mater. Res. Technol. 13 (2021) 561–572.

M.L. Ye, M.J. Zhao, S. Chen, S.F. Yang, J.S. Li, Metals 10 (2020) 1438.

M.J. Zhao, Y. Wang, S.F. Yang, M.L. Ye, J.S. Li, Y.H. Liu, Metals 11 (2021) 722.

Acknowledgements

I would like to thank Dr. Nai-liang Cheng, Dr. Yong-feng Chen, and Graham Hughes for their assistance with the Plasma heating experiments and their valuable suggestions and discussion. This work was supported by the National Natural Science Foundation of China (Grant No. 52074030).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wang, Y., Wang, C., Zhao, Mj. et al. Development and application of a multi-graphite electrode DC plasma tundish heating. J. Iron Steel Res. Int. 29, 1800–1806 (2022). https://doi.org/10.1007/s42243-022-00778-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-022-00778-4