Abstract

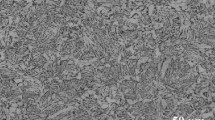

The sulfide stress corrosion (SSC) behaviors of the high strength low alloy steel at the different temperatures were investigated by the microstructural observation and electrochemical noise (EN) analysis. With the corrosion temperature increasing from 20 to 40 °C, SSC ruptured time is prolonged. The increase in corrosion temperature results in the decrease of the saturation solubility of H2S in the solution and thus increases pH value of solution. The increase in corrosion temperature decreases the size of the holes and cracks in the corrosion product film on the surface of the sample, which is due to the formation of the dense FeS corrosion product film. The current kurtosis results indicate that the time for the first occurrence of crack initiation is postponed by the increase in the corrosion temperature. The standard deviation of current noise signals, current kurtosis, power spectral density and energy distribution plot results shows a great consistency, which suggests that EN analysis method can reflect SSC behaviors in real time.

Similar content being viewed by others

References

L.F. Porter, P.E. Repas, JOM 34 (1982) 14–21.

N.J. Kim, JOM 35 (1983) 21–27.

Y. Shao, C. Liu, Z. Yan, H. Li, Y. Liu, J. Mater. Sci. Technol. 34 (2018) 737–744.

X. Li, L. Shi, Y. Liu, K. Gan, C. Liu, Mater. Sci. Eng. A 772 (2020) 138683.

B. Beidokhti, A. Dolati, A.H. Koukabi, Mater. Sci. Eng. A 507 (2009) 167–173.

M. Al-Mansour, A.M. Alfantazi, M. El-boujdaini, Mater. Des. 30 (2009) 4088–4094.

M.C. Zhao, B. Tang, Y.Y. Shan, K. Yang, Metall. Mater. Trans. A 34 (2003) 1089–1096.

P.R. Rhodes, Corrosion 57 (2001) 923–966.

J.M. Zhang, W.H. Sun, S. Hao, J. Iron Steel Res. Int. 17 (2010) No. 10, 63–67.

M.J. Kim, S.H. Lee, J.G. Kim, J.B. Yoon, Corrosion 66 (2010) 125005.

S.W. Ciaraldi, Corrosion 40 (1984) 77–81.

R.A. Carneiro, R.C. Ratnapuli, V.D.F.C. Lins, Mater. Sci. Eng. A 357 (2003) 104–110.

X.B. Shi, W. Yan, W. Wang, L.Y. Zhao, Y.Y. Shan, K. Yang, J. Iron Steel Res. Int. 22 (2015) 937–942.

H. Ma, C. Du, Z. Liu, Y. Li, X. Li, Acta Metall. Sin. 55 (2019) 469–479.

D.H. Xia, Y. Behnamian, J.L. Luo, J. Electrochem. Soc. 166 (2019) C49–C64.

D.H. Xia, J. Wang, Z. Qin, Z. Gao, Z. Wu, J. Wang, L. Yang, W. Hu, J.L. Luo, Mater. Chem. Phys. 233 (2019) 133–140.

E. Quadrini, Mater. Chem. Phys. 20 (1988) 73–85.

S. Gao, P. Jin, B. Brown, D. Young, S. Nešić, M. Singer, Corrosion 73 (2017) 1188–1191.

L. Khaksar, G. Whelan, J. Shirokoff, Int. J. Corros. 2016 (2016) 1025261.

P.C. Okonkwo, M.H. Sliem, R.A. Shakoor, A.M.A. Mohamed, A.M. Abdullah, J. Mater. Eng. Perform. 26 (2017) 3775–3783.

C.J.O. Alonso, M.A. Lucio-Garcia, I.A. Hermoso-Diaz, J.G. Chacon-Nava, A. Martinez-Villafane, J.G. Gonzalez-Rodriguez, Int. J. Electrochem. Sci. 9 (2014) 6717–6733.

J. Kovač, M. Leban, A. Legat, Electrochim. Acta 52 (2007) 7607–7616.

D.H. Xia, S. Song, L. Tao, Z. Qin, Z. Wu, Z. Gao, J. Wang, W. Hu, Y. Behnamian, J.L. Luo, J. Mater. Sci. Technol. 53 (2020) 146–162.

X. Li, J. Song, K. Gan, D.H. Xia, Z. Gao, C. Liu, Y. Liu, J. Electroanal. Chem. 876 (2020) 114480.

C. Mao, C. Liu, L. Yu, H. Li, Y. Liu, Mater. Des. 197 (2021) 109252.

N. Standard, TM0177-2016 Labortory Testing of Metals for Resistance to Sulfide Stress Cracking and Stress Corrosion Cracking in H2S Environments, NACE International: Houston, TX, USA, 2016.

D.H. Xia, S. Song, Y. Behnamian, W. Hu, Y.F. Cheng, J.L. Luo, F. Huet, J. Electrochem. Soc. 167 (2020) 081507.

Y. Teng, Chinese journal of Arid Environmental Monitoring 8 (1994) No. 1, 11–14.

H.Y. Ma, X.L. Cheng, S.H. Chen, C. Wang, J.P. Zhang, H.Q. Yang, J. Electroanal. Chem. 451 (1998) 11–17.

H. Ma, X. Cheng, G. Li, S. Chen, Z. Quan, S. Zhao, L. Niu, Corros. Sci. 42 (2000) 1669–1683.

H. Tian, X. Wang, Z. Cui, Q. Lu, L. Wang, L. Lei, Y. Li, D. Zhang, Corros. Sci. 144 (2018) 145–162.

H. Tian, J. Xin, Y. Li, X. Wang, Z. Cui, Corros. Sci. 158 (2019) 108089.

D. Rickard, G.W. Luther, Chem. Rev. 107 (2007) 514–562.

F.H. Meyer, O.L. Riggs, R.L. McGlasson, J.D. Sudbury, Corrosion 14 (1958) 69–75.

W. Hao, Z. Liu, W. Wu, X. Li, C. Du, D. Zhang, Mater. Sci. Eng. A 710 (2017) 318–328.

U. Bertocci, C. Gabrielli, F. Huet, M. Keddam, J. Electrochem. Soc. 144 (1997) 31–37.

Y.J. Tan, S. Bailey, B. Kinsella, Corros. Sci. 38 (1996) 1681–1695.

S. Reid, G.E.C. Bell, G.L. Edgemon, The use of skewness, kurtosis and neural networks for determining corrosion mechanism from electrochemical noise data, NACE International, Houston, US, 1998.

R.A. Cottis, M.A.A. Al-Awadhi, H. Al-Mazeedi, S. Turgoose, Electrochim. Acta 46 (2001) 3665–3674.

K. Hladky, L.J. Dawson, Corros. Sci. 22 (1982) 231–237.

J. Flis, J.L. Dawson, J. Gill, G.C. Wood, Corros. Sci. 32 (1991) 877–892.

J.C.Uruchurtu, J.L. Dawson, Corrosion 43 (1987) 19–26.

C. Ma, S. Song, Z. Gao, J. Wang, W. Hu, Y. Behnamian, D.H. Xia, Corros. Eng. Sci. Technol. 52 (2017) 432–440.

Acknowledgements

The authors are grateful to the National Natural Science Foundation of China (Grant Nos. 51975404, 52034004 and 52171123) for grant and financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Xh., Liu, Cx., He, B. et al. Analysis of cracks origin behaviors during sulfide stress corrosion (SSC) in HSLA steel at different temperatures by electrochemical noise. J. Iron Steel Res. Int. 29, 1836–1845 (2022). https://doi.org/10.1007/s42243-021-00704-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-021-00704-0